Distillation seawater desalting system using expander and compressor

An expander and compressor technology, applied in seawater treatment, general water supply saving, heating water/sewage treatment, etc., can solve the problems of low energy utilization efficiency, increased equipment investment, poor adjustability, etc., to improve steam utilization efficiency, Realize the effect of efficient utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

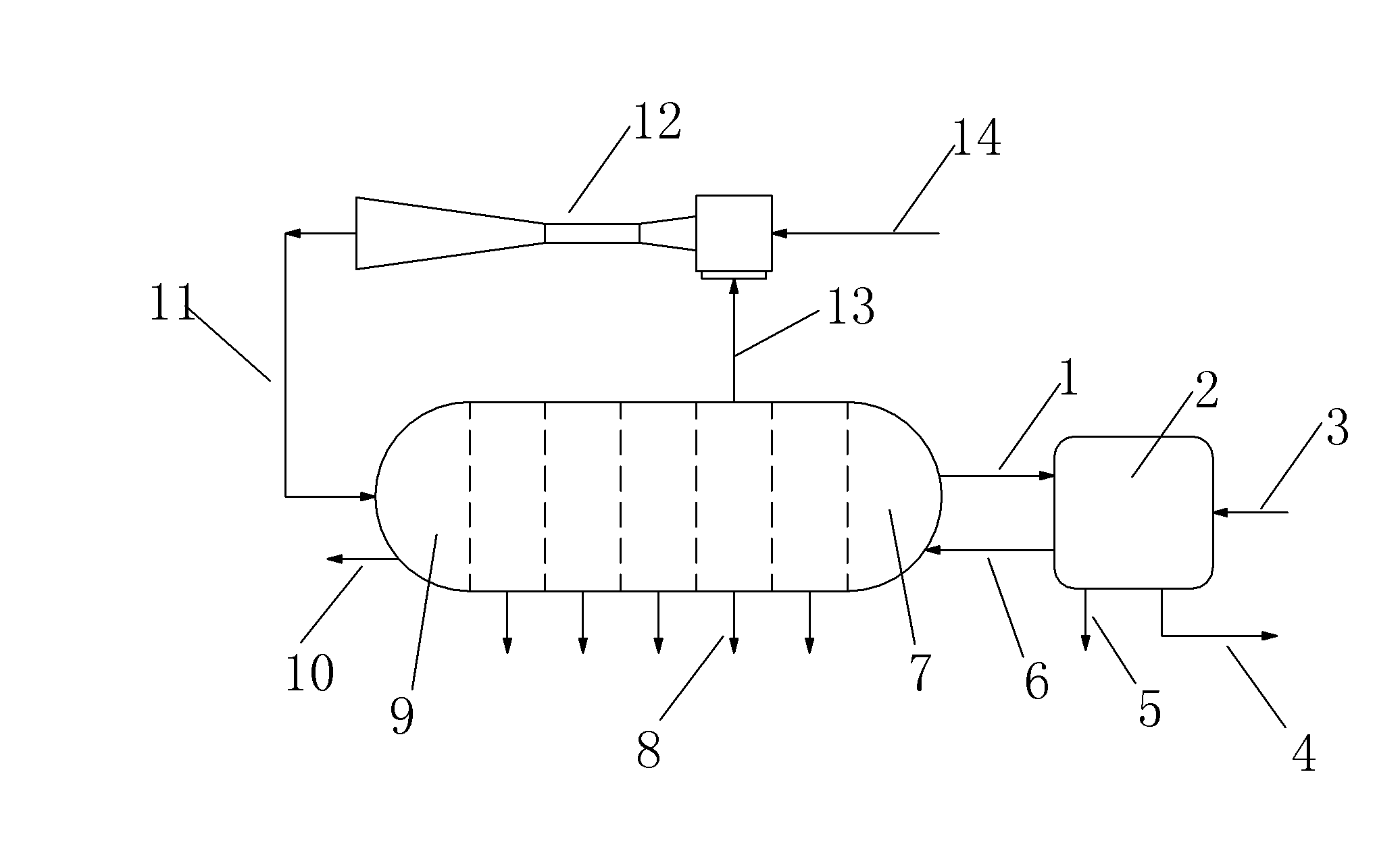

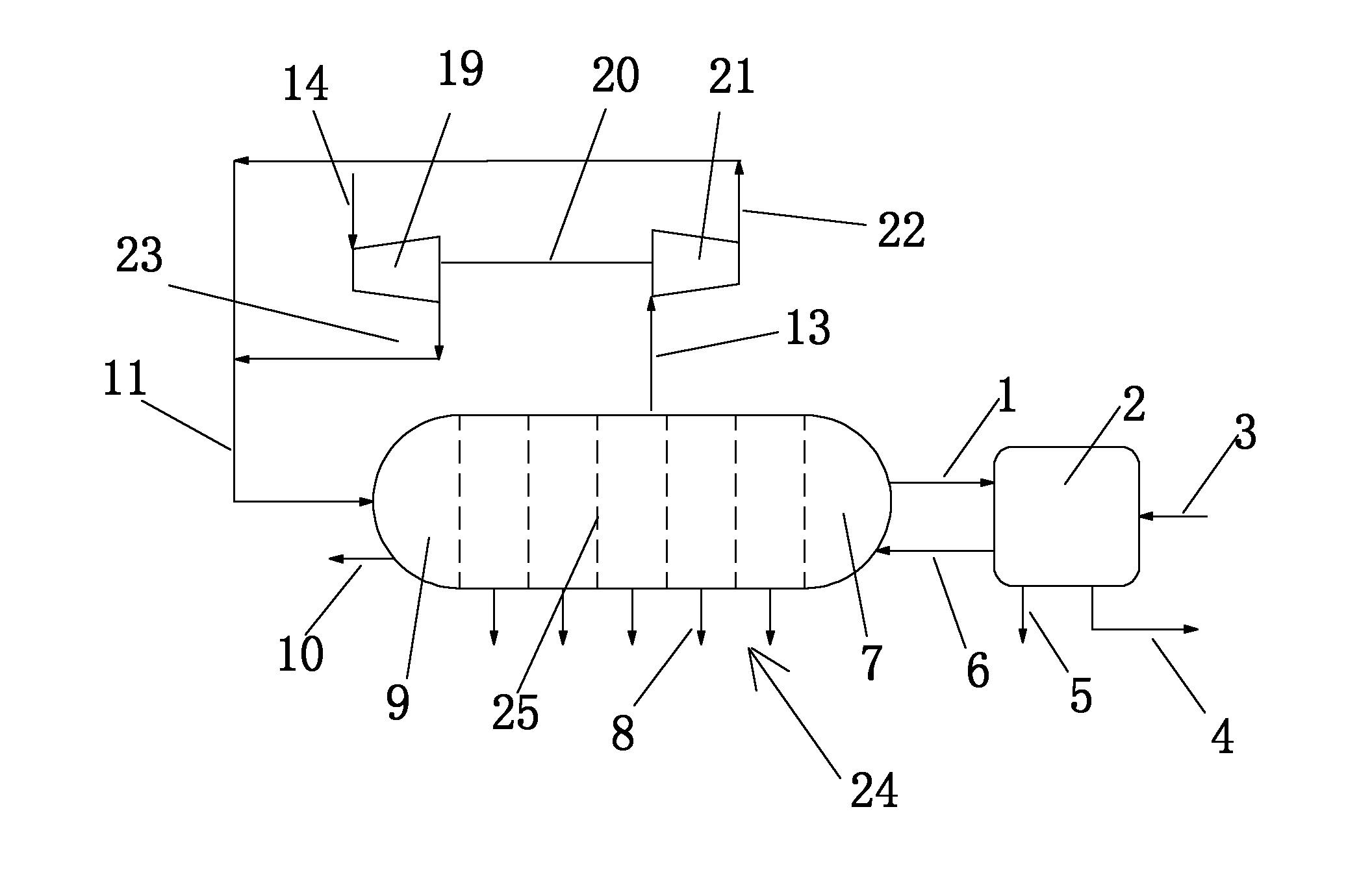

[0034] The distillation seawater desalination system using an expander and a compressor of the present invention will be described in detail below with reference to the embodiments and the accompanying drawings.

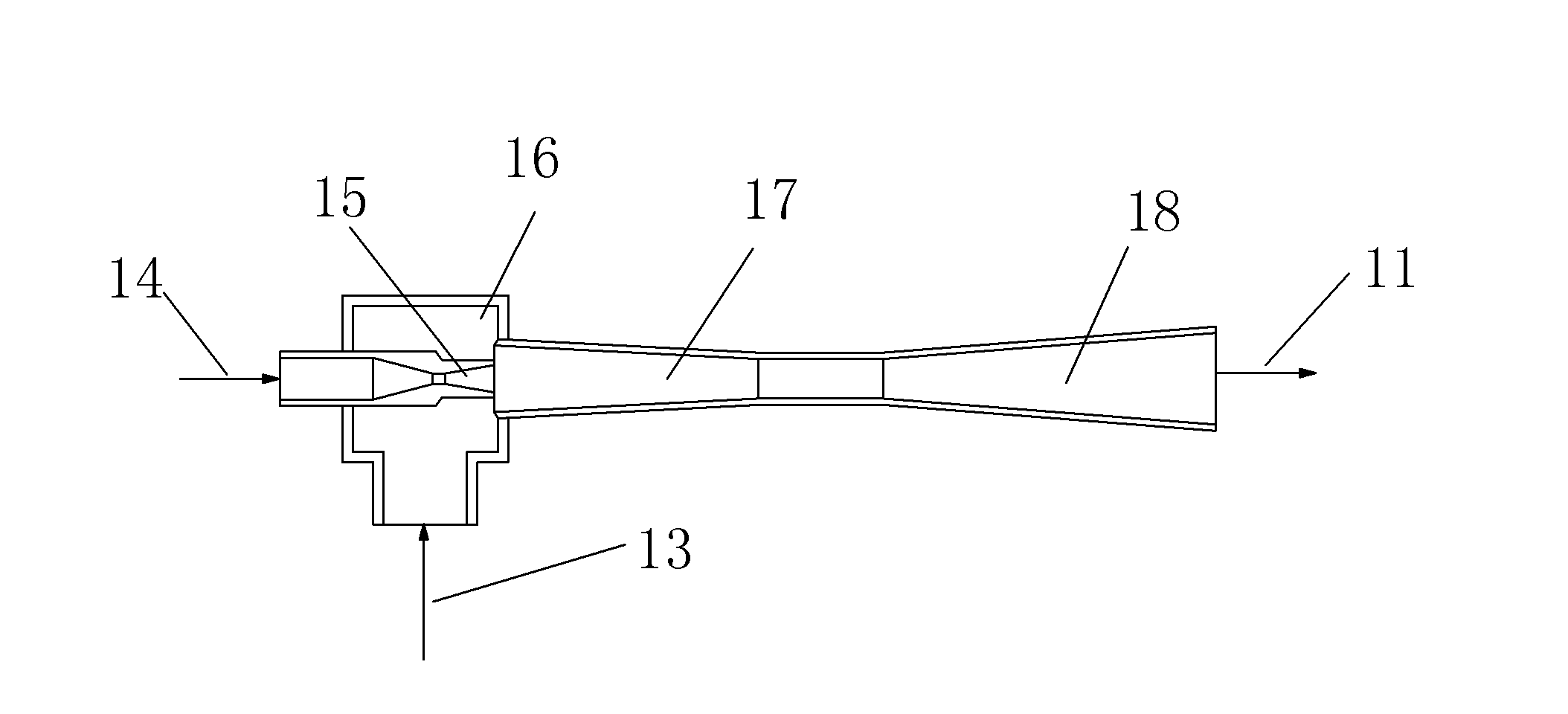

[0035] The main difference between the distillation seawater desalination system using an expander and a compressor of the present invention and the multi-effect distillation seawater desalination system widely used at present is that the traditional multi-effect distillation system is replaced by a combination of an expander and a compressor with higher energy efficiency steam jet pump in. in,

[0036] The expander can expand the input high-pressure working steam, reduce the pressure, and then input it into the first-effect evaporator; at the same time, the expansion of steam in the expander works to drive the compressor to compress the low-pressure steam of the intermediate-effect or final-effect evaporator, increasing the steam pressure and Re-enter the first eff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com