Gas producer with double-bell jar coal bearing device

A technology of gas generator and gas furnace, which is applied in the manufacture of combustible gas and petroleum industry, etc. It can solve the problems of threatening the health of operators, incomplete combustion of fuel, waste of raw materials, etc., so as to avoid energy loss, prevent gas leakage, The effect of reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with specific drawings and embodiments.

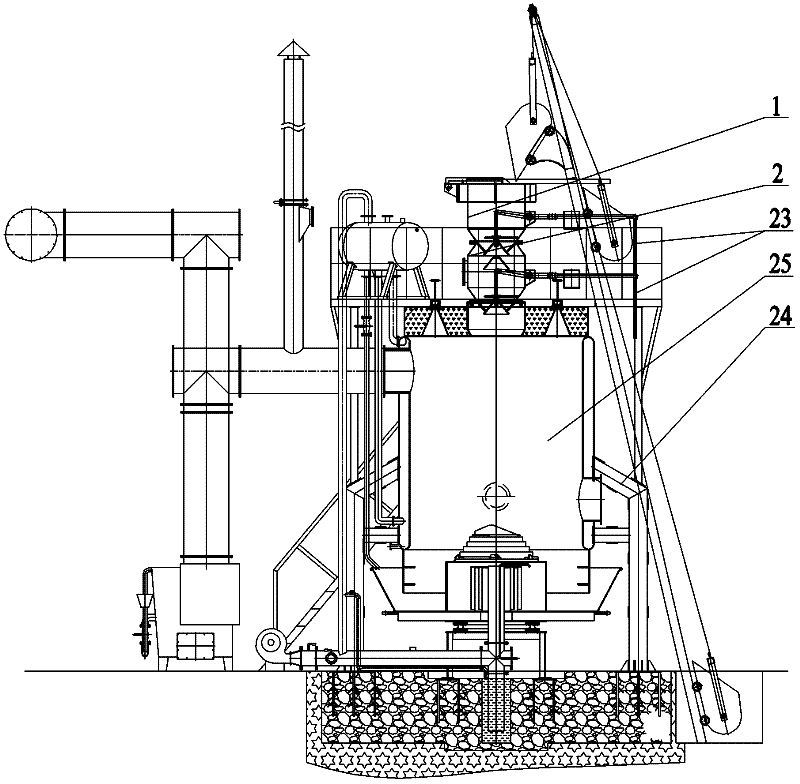

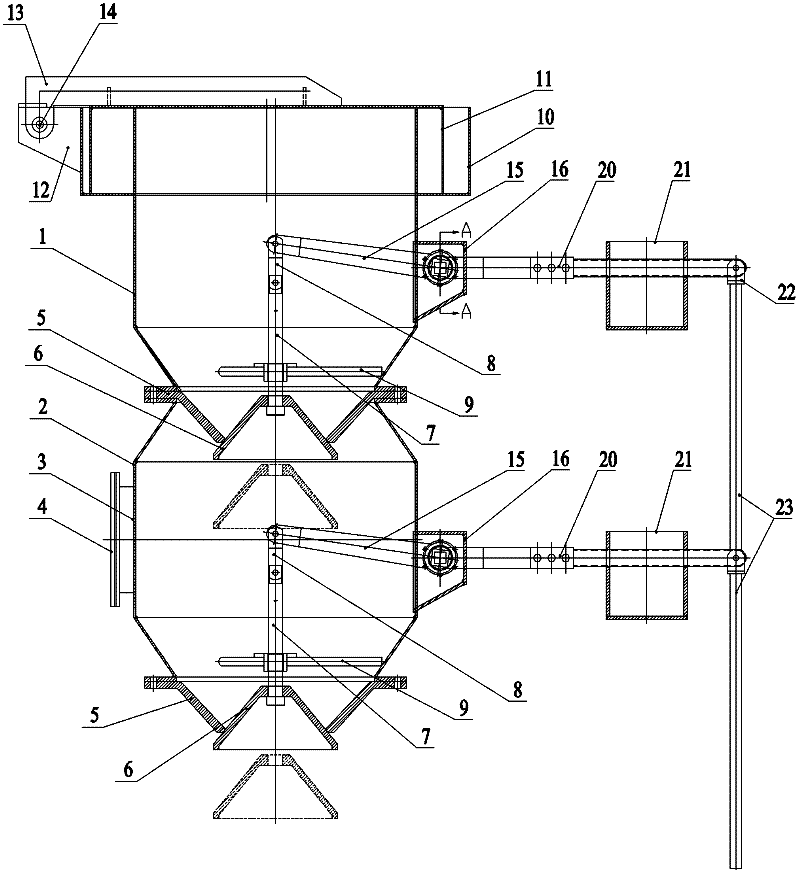

[0028] As shown in the figure, the gas furnace in the embodiment has a gas furnace body 25 fixedly installed on the furnace body support 24, and the gas furnace body 25 has a gas bag, a feeding mechanism, an ash discharge mechanism, a ventilation mechanism and a gas interface. mechanism, a double bell jar coal bearing device is installed on the top of the gas furnace body 25, the double bell jar coal bearing device mainly consists of an upper coal hopper 1, a lower coal hopper 2, a cover mechanism, a material cup 6 and a material cup The lifting mechanism consists of several parts.

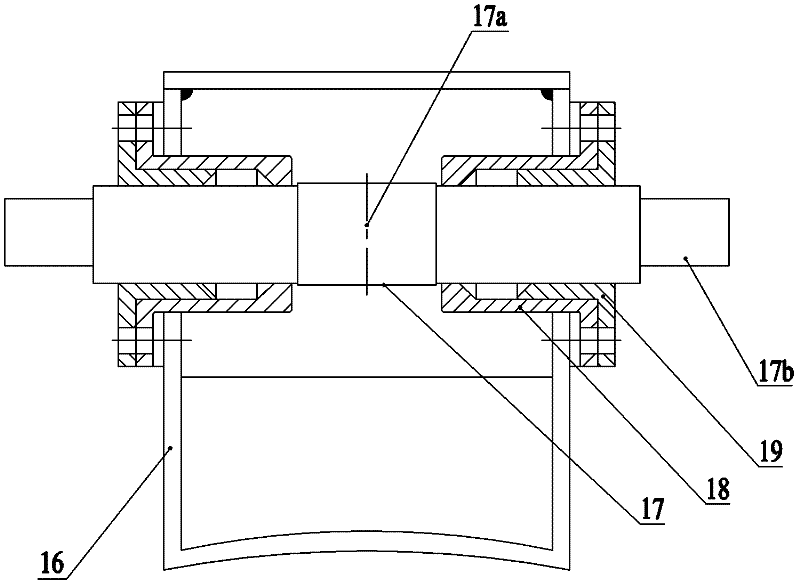

[0029] like figure 1 As shown, the charging port of the upper coal hopper 1 is equipped with a cover plate mechanism, and the discharge port of the upper coal hopper 1 is equipped with a sealing seat 5, and the lower end of the sealing seat 5 extends into the feeding port of the l...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap