Latch needle bed assembly of double-needle-bed tricot machine

A double needle bed warp knitting machine and latch needle bed technology, which is applied in the field of latch needle bed components, can solve the problems of extremely high machining accuracy requirements, increased production costs, large needle groove deviation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

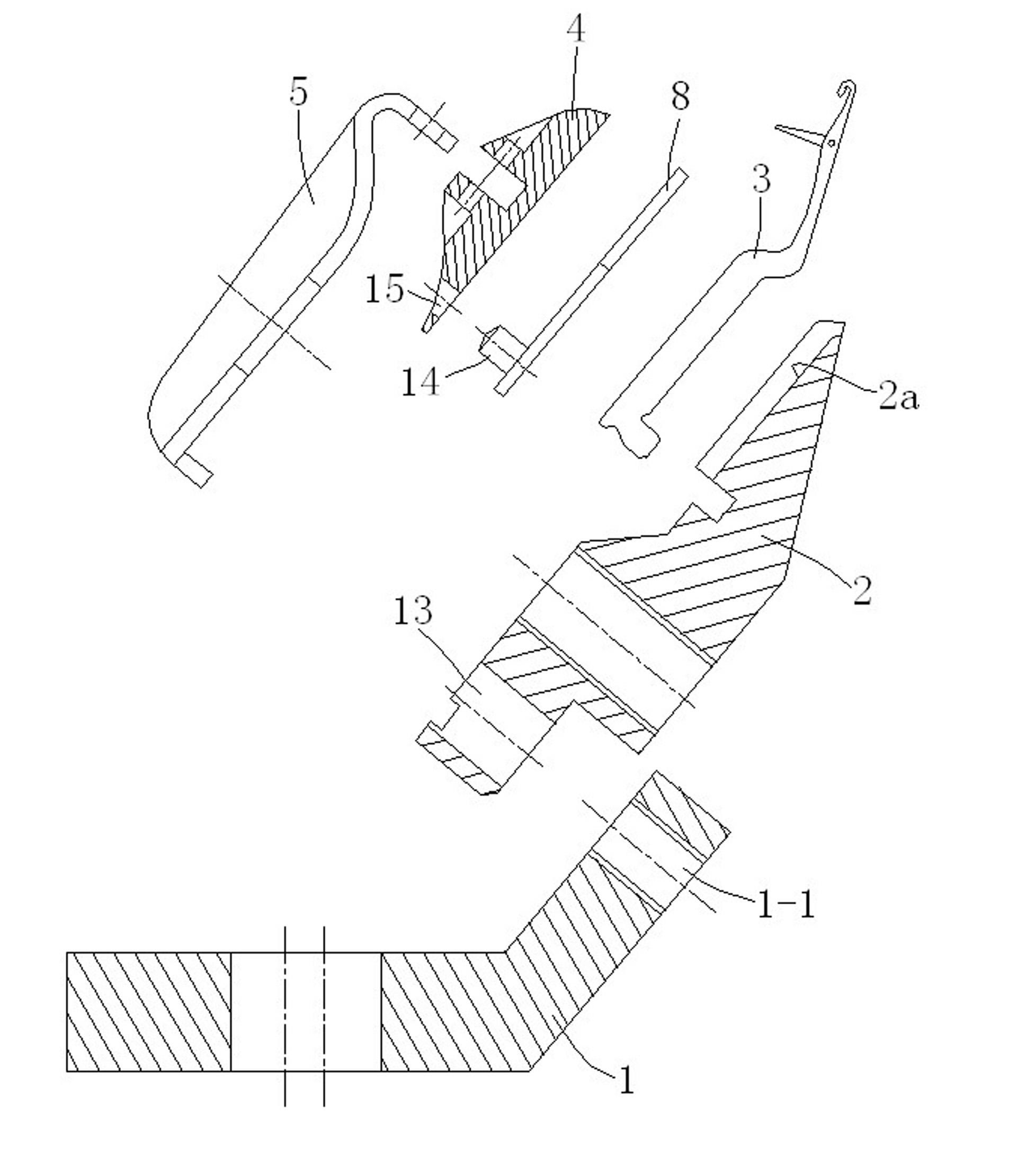

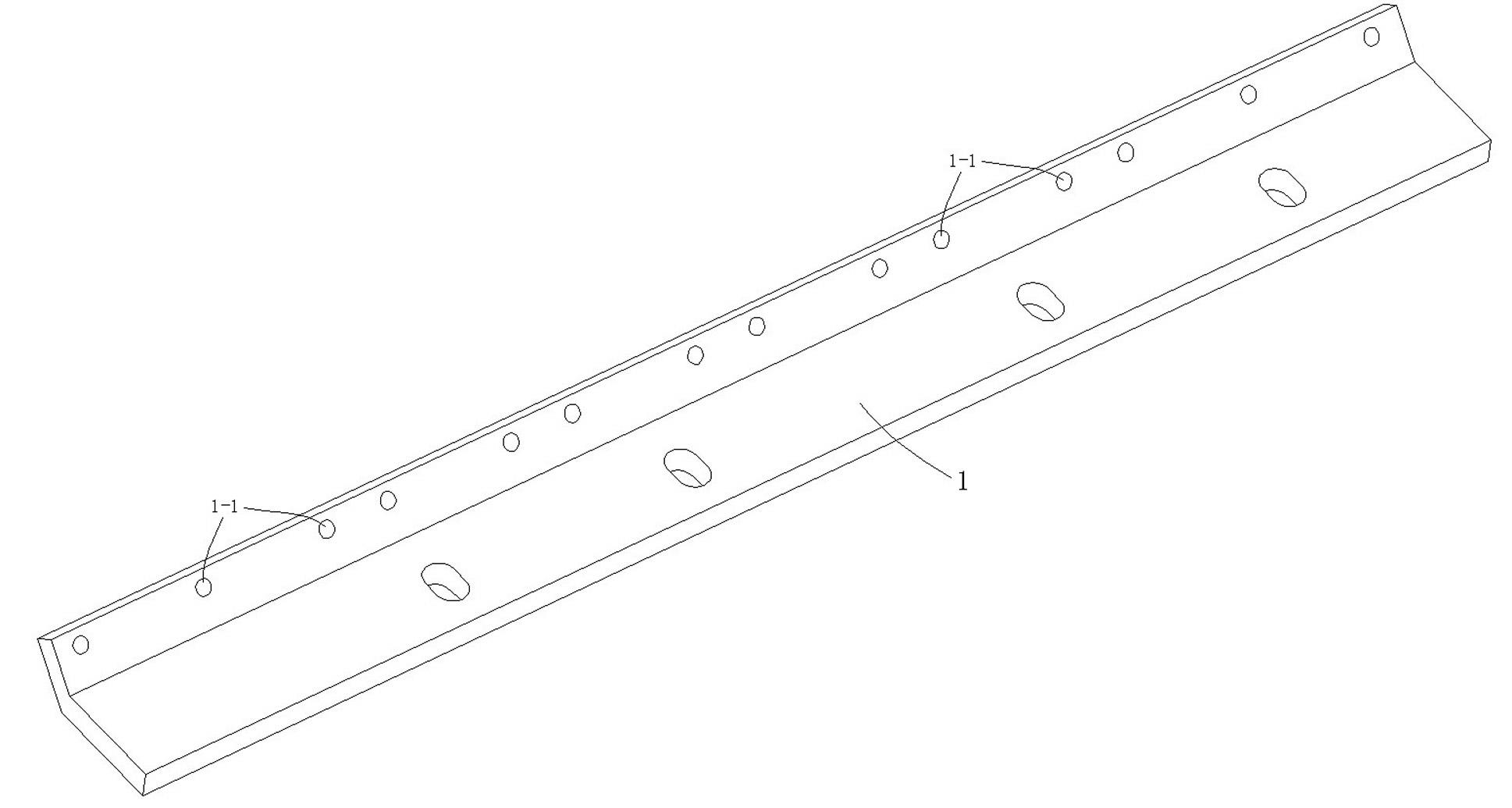

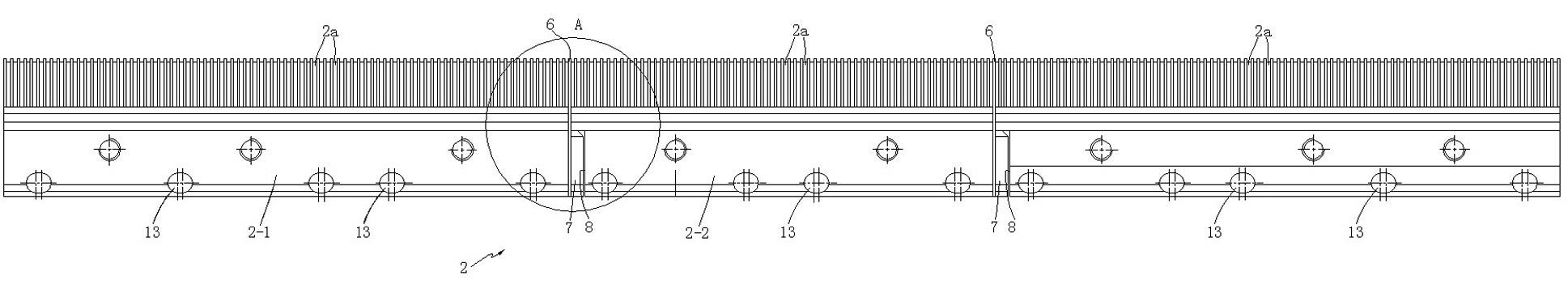

[0026] see Figure 1 to Figure 14 The illustrated latch needle bed assembly of a double needle bed warp knitting machine includes a needle bed base 1, a needle groove plate 2, a latch needle 3, a needle pressure plate 4 and a stamping plate 5; There are some needle grooves 2a matched with the latch needles 3, the stamping plate 5 passes through the needle pressing plate 4 and bolts are used to press the latch needles 3 into the needle grooves 2a of the needle groove plate 2 , the needle groove plate 2 is separated from the needle bed base 1, and the needle groove plate 2 is composed of a plurality of independent small needle groove plates, and each small needle groove plate is connected with the needle bed base respectively 1 fixedly connected, the latch needle bed assembly also includes a latch needle for adjusting the distance between the latch needles at the junction of the adjacent small needle groove plates 2-1, 2-2 and making the adjacent small needle groove plates 2-1, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com