Dynamic testing method of thickness of battery AGM (absorbent glass mat) separator and testing device thereof

A testing method and testing device technology, applied in the direction of measuring devices, optical devices, mechanical thickness measurement, etc., to achieve the effects of simple operation, improvement of key quality indicators, and improvement of the utilization rate of finished products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

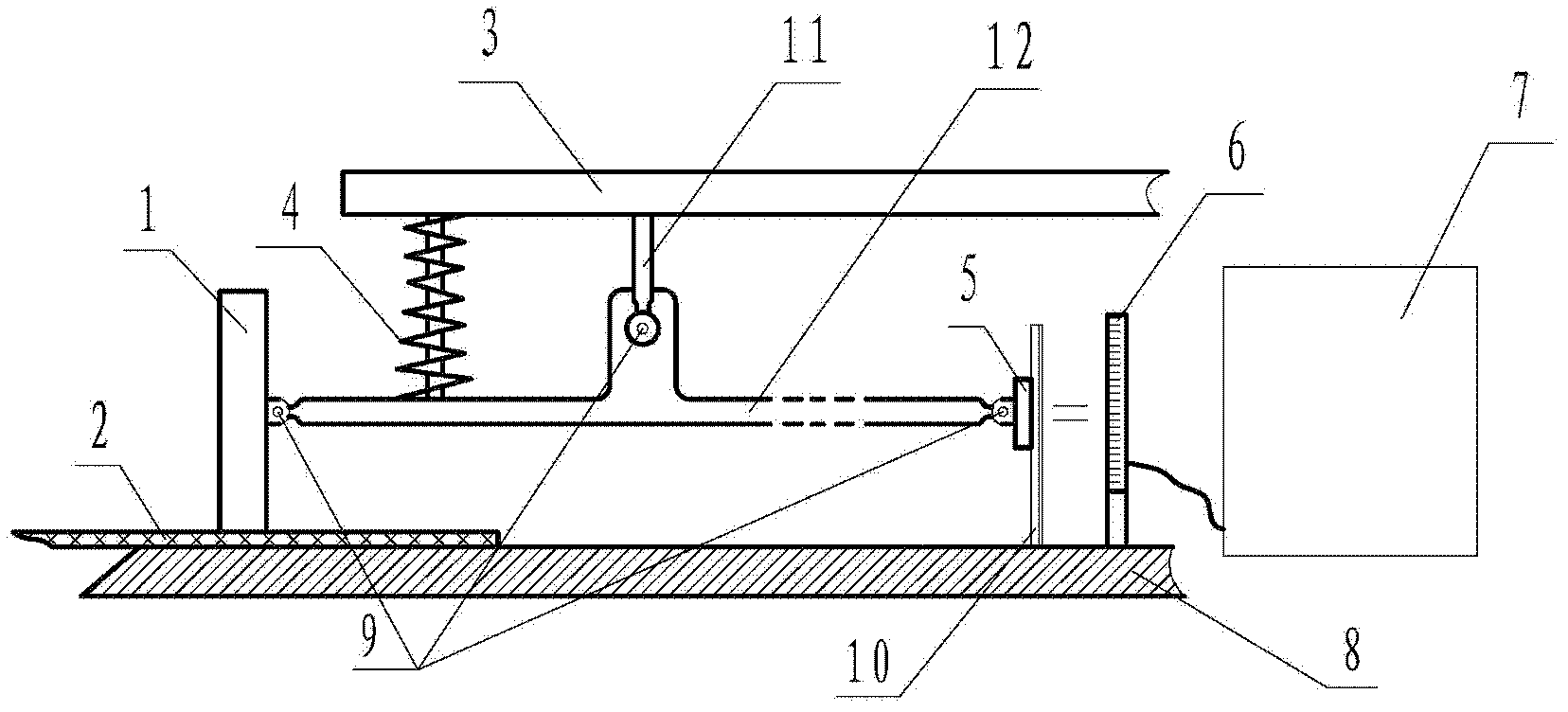

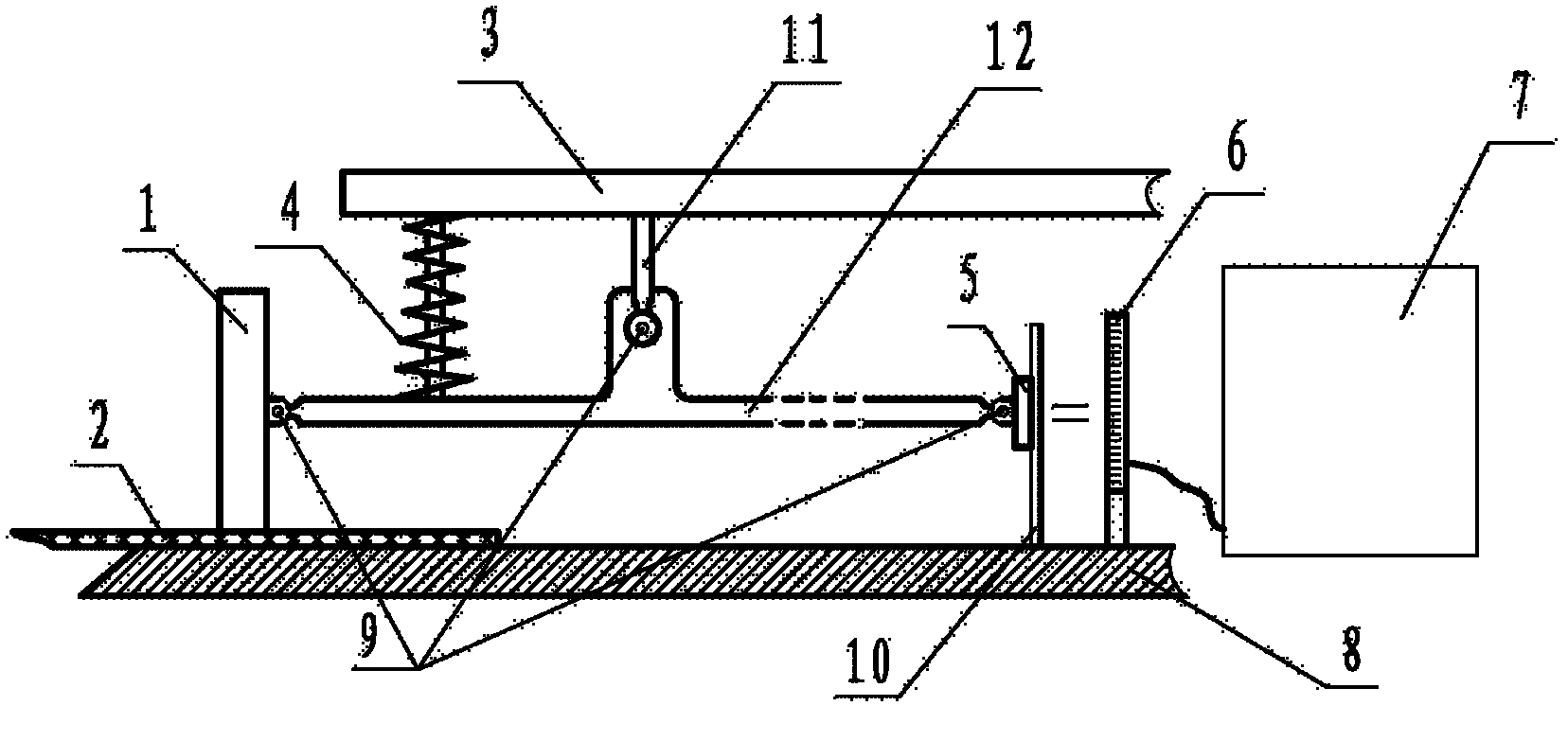

[0023] The method of testing the dynamic thickness of the battery AGM separator is: flatten the AGM separator on a reference surface, and measure the thickness by dynamically pressing a thickness sensing head from the surface of the AGM separator, and the sensed thickness is measured by a lever device. After the thickness value is physically amplified, the photoelectric signal is transmitted to a grating ruler to realize the signal identification, and finally the measured thickness data is displayed and stored through computer data processing.

[0024] The test device used in the battery AGM separator dynamic thickness test method: a horizontal fixed bridge 3, the fixed bridge 3 extends downwards a support arm 11, the lower end of the support arm 11 is movably connected to a fulcrum of a lever through a rotating shaft 9, At a place deviated from the fulcrum of the lever, a return spring 4 is connected between the fixed bridge 3 and the lever, the front end of the short arm of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com