Full-automatic optical thickness gauge and refractive index/transmittance data processing method thereof

An optical thickness gauge and data processing technology, applied in the direction of using optical devices, instruments, measuring devices, etc., can solve the problem that it is difficult to ensure the quality of coating, increase the work intensity of coating operators, and it is difficult to ensure the accuracy and precision of measurement and other issues to achieve the effect of eliminating interference, accurate judgment, and more content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below in conjunction with accompanying drawing, the present invention is described in further detail:

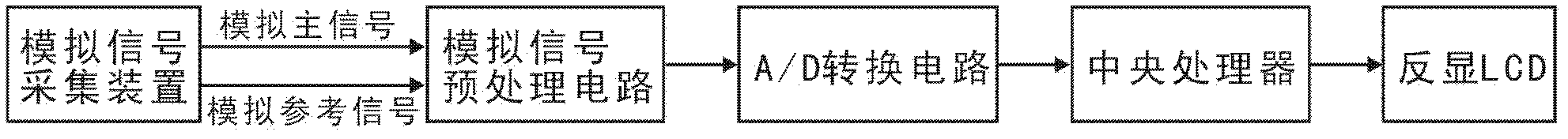

[0032] Such as figure 1 As shown, the fully automatic optical thickness gauge among the present invention comprises analog signal acquisition device, analog signal preprocessing circuit, A / D conversion circuit, central processing unit and anti-display LCD, the signal output end of analog signal acquisition device and analog signal The signal input end of the preprocessing circuit is connected, the signal output end of the analog signal preprocessing circuit is connected with the signal input end of the A / D conversion circuit, the signal output end of the A / D conversion circuit is connected with the refraction / transmittance data signal of the central processing unit The input end is connected, and the video signal output end of the central processing unit is connected with the signal input end of the reverse display LCD.

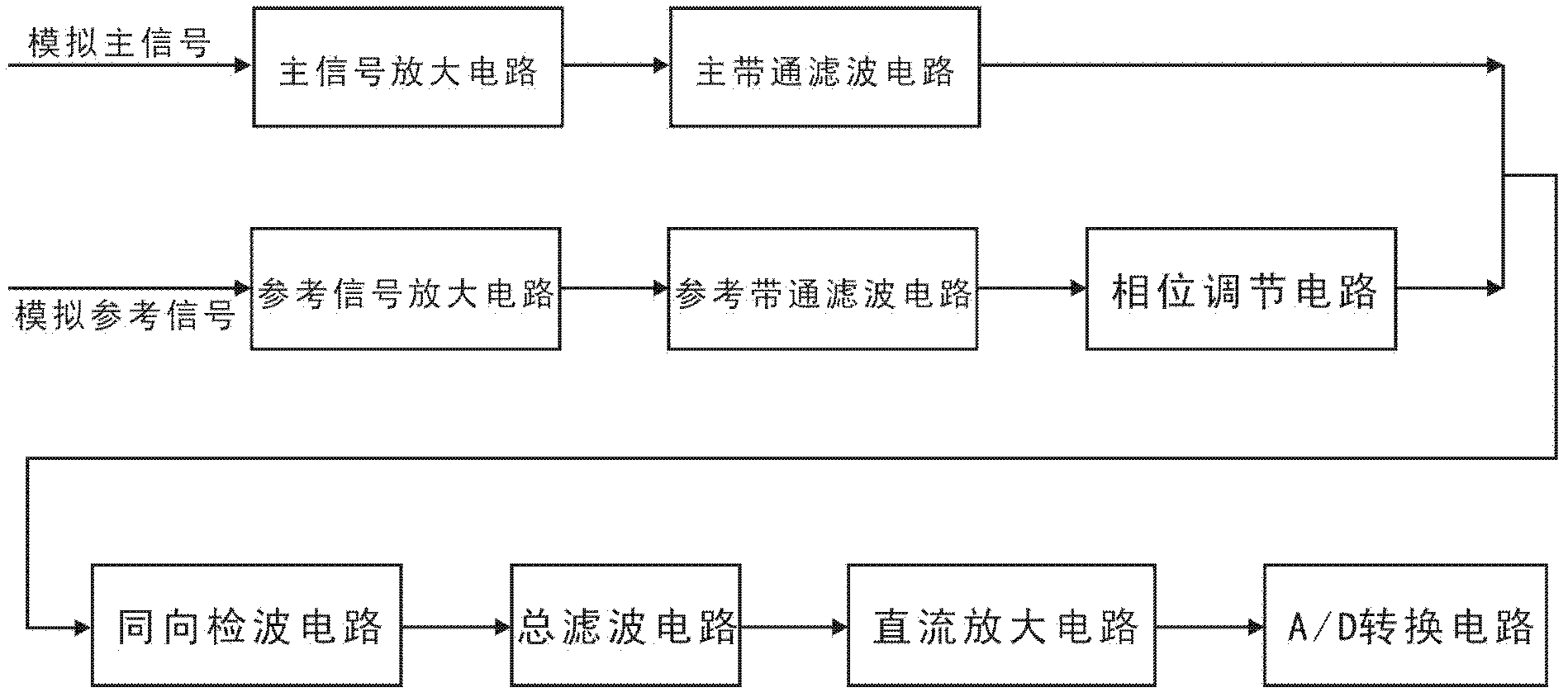

[0033] Such as figure 2 As shown, the analo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com