Outer diameter measuring instrument for big size shaft type parts

A technology for shaft parts and measuring instruments, applied in the field of measuring tools, can solve the problems of error change, difficulty in measuring bow height and chord length, and error amplification, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

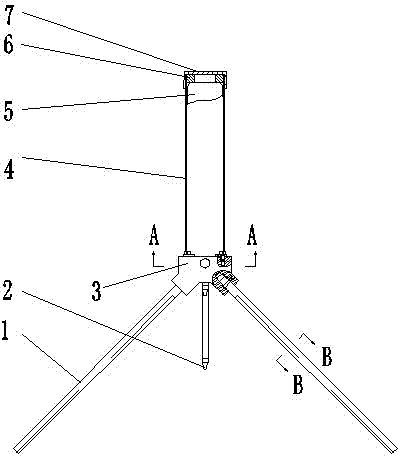

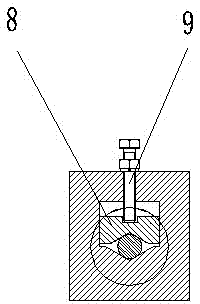

[0018] Such as figure 1 As shown in the figure, a measuring instrument for the outer diameter of large-sized shaft parts uses the measuring principle of the three-point contact method on a circle, and mainly consists of an angle arm 1, a grating scale 5, a base 3, a top block 8, and a sleeve 4 , locking bolt 9, signal processing circuit, single-chip microcomputer, liquid crystal display (LCD) and other components. The cross-section of the angle arm 1 adopts a double-arc top concave structure. During measurement, by adjusting the contact between the double-arc top of the angle arm and the outer diameter of the workpiece, the perpendicularity between the angle arm and the axis of the workpiece to be measured is ensured. The two angled arms 1 are symmetrically arranged under the base 3, and the angled arms 1 and the base 3 adopt a taper interference fit, and the value of the opening angle is determined by the angle between the axes of the two taper holes on the base. The base 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com