Long-distance automatic verification system of digital display type temperature indicating instrument

A technology of indicating instrument and digital display, which is applied in the field of remote automatic verification system of digital display temperature indicating instrument, can solve the problems of time-consuming and laborious, restricting the efficiency of automatic verification, affecting the objectivity of the verification process, etc., so as to reduce the cost of verification and improve the accuracy of verification. efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

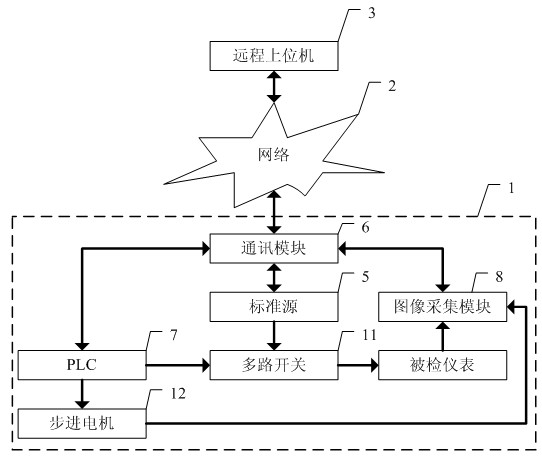

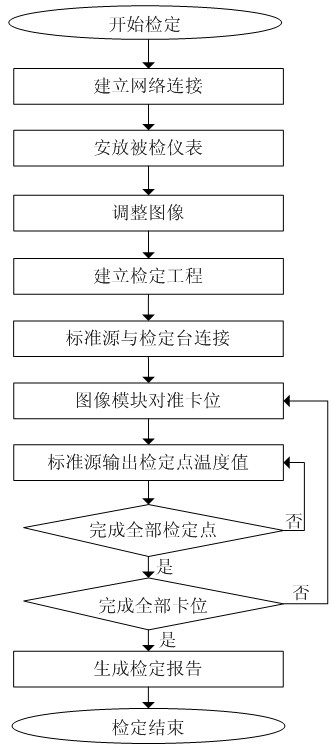

[0017] Such as figure 1 As shown, the present invention includes a field terminal 1, a network 2 and a remote host computer 3; the communication module 6 in the field terminal (1) is connected to the remote host computer 3 via the network 2. The medium of data transmission in the network 2 is Ethernet; the upper computer 3 at the remote end is mainly responsible for data processing and controlling the field end 1 through the network 2 . It can realize the separation of data collection and data processing, and the tested instrument can be calibrated by the superior certifying agency without sending it for censoring.

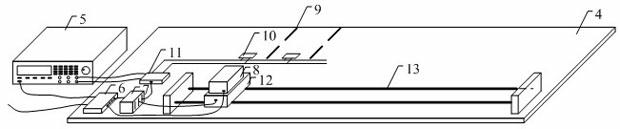

[0018] One of the standard sources 5 in the field terminal 1 is connected to the communication module 6 through RS232 and GPIB, and the other is connected to the multi-way switch 11; the stepping motor 12 is connected to the image acquisit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com