Optimized cutter selecting method for numerical control milling for free-form surface

A CNC milling and curved surface technology, applied in the direction of program control, computer control, general control system, etc., can solve problems such as tool interference, achieve the effect of ensuring accuracy, improving processing efficiency and effect, and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

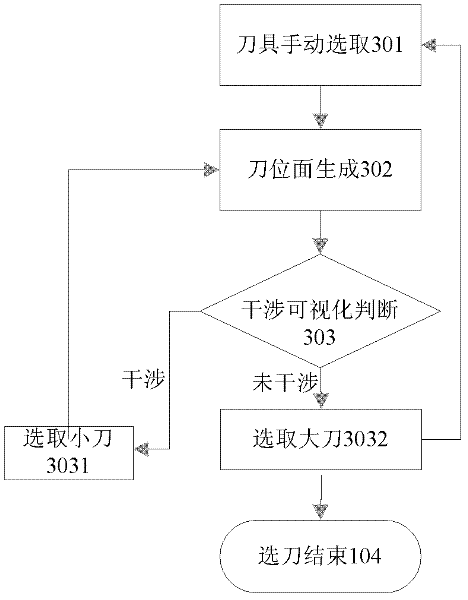

[0018] The present invention constructs a curved surface to be processed through the point cloud, which is a cubic NURBS curved surface. Spherical milling cutters with diameters of φ4, φ6, φ8, φ10, φ16 and φ20 can be used to generate equidistant tool positions for the same free-form surface; surface. Then by observing the tool position surface, it can be judged whether tool interference occurs.

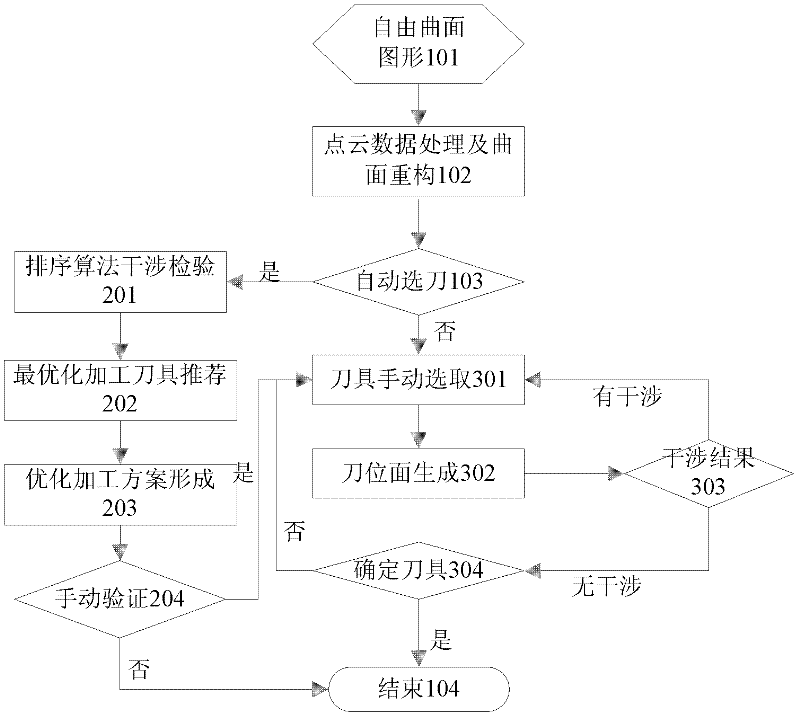

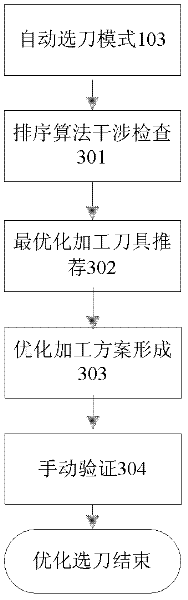

[0019] see figure 1 , the numerical control milling process optimization tool selection method of free-form surface of the present invention, comprises the following steps:

[0020] S101. Obtain point cloud data or CAD three-dimensional graphics of free-form surface graphics;

[0021] S102, processing point cloud data, and reconstructing a free-form surface;

[0022] S103, whether to use the automatic tool selection mode, if the automatic tool selection mode is adopted, then go to step S201, otherwise, if the manual tool selection mode is adopted, then go to step S301;

[0023] S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com