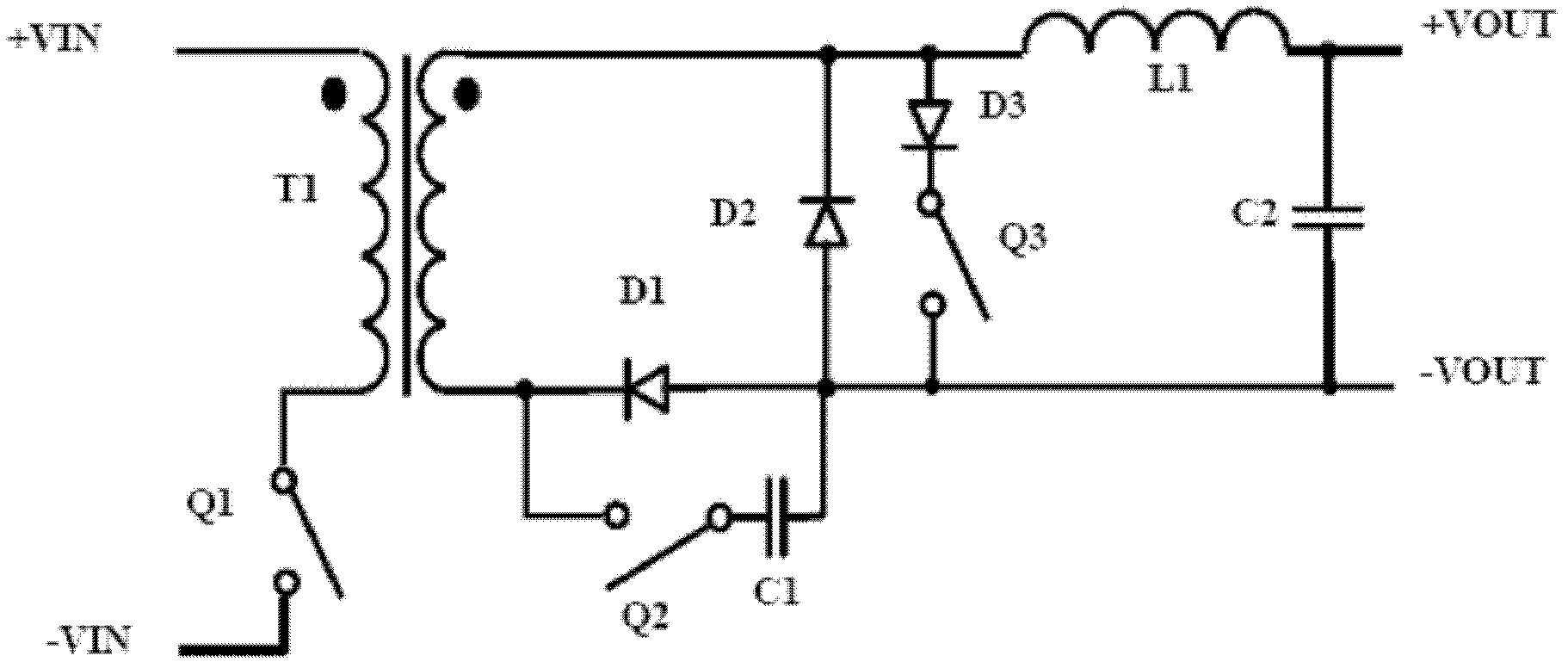

Single-end forward power inverter

A forward converter, single-ended technology, applied in the direction of converting DC power input to DC power output, output power conversion devices, instruments, etc., can solve the problem that the secondary side diode circuit cannot be used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

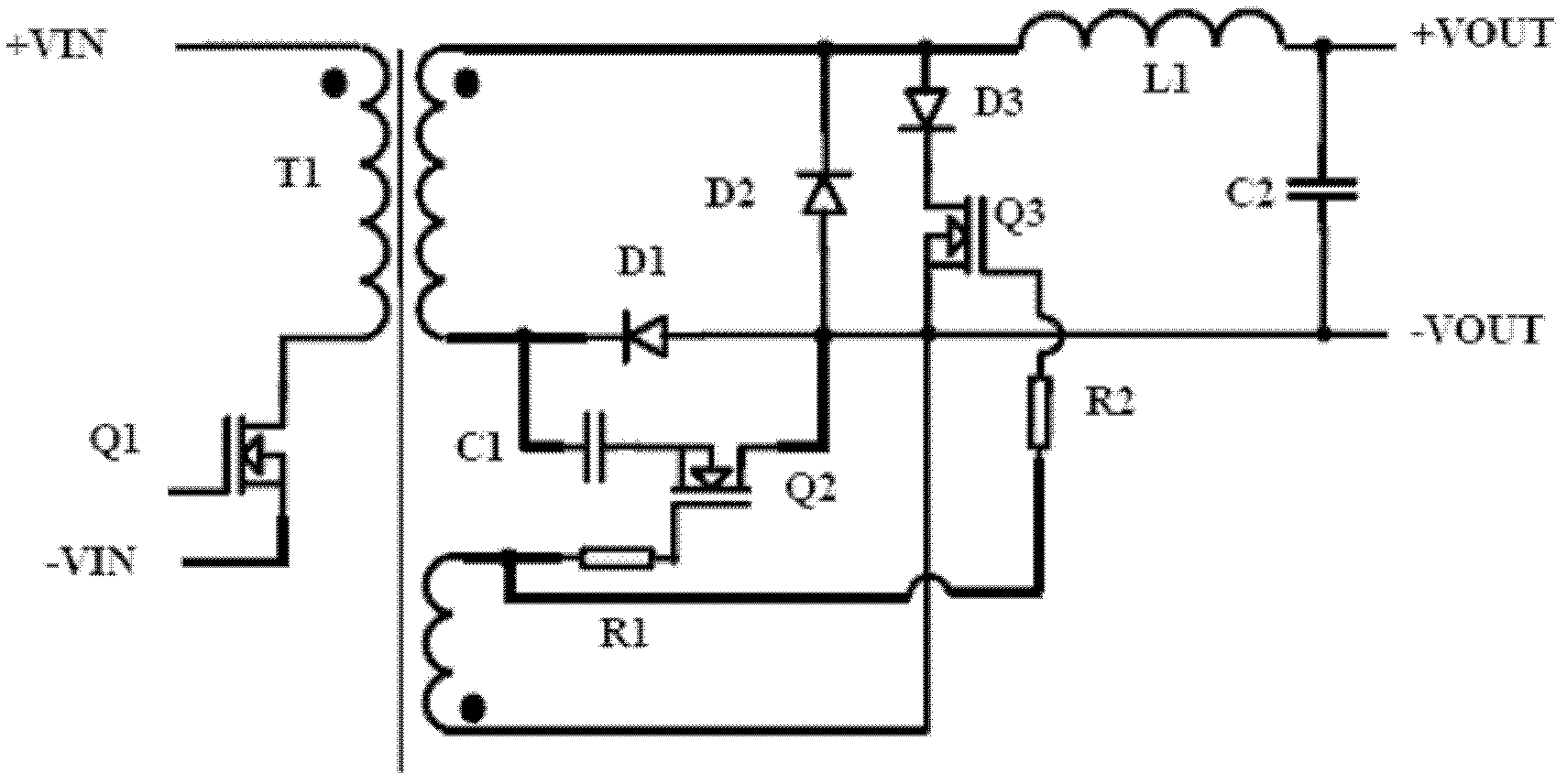

Embodiment 1

[0029] figure 2 The specific circuit schematic diagram of the single-ended forward converter provided by this embodiment is shown, as figure 2 As shown, in this embodiment, both the clamp transistor Q2 and the discharge transistor Q3 are NMOS transistors.

[0030] figure 2 neutralize figure 1 The same components and connection relationship in the above will not be repeated here, and only the connection relationship of the components related to the clamping tube Q2 and the discharge tube Q3 will be described.

[0031] The source of the clamping tube Q2 is connected to one end of the clamping capacitor C1, and the other end of the clamping capacitor C1 is connected to the cathode of the rectifier tube D1, and the gate of the clamping tube Q2 is connected to the differential voltage of the auxiliary winding of the transformer T through the resistor R1 Famous end.

[0032] The source of the discharge tube Q3 is connected to the anode of the freewheeling tube D2, the drain o...

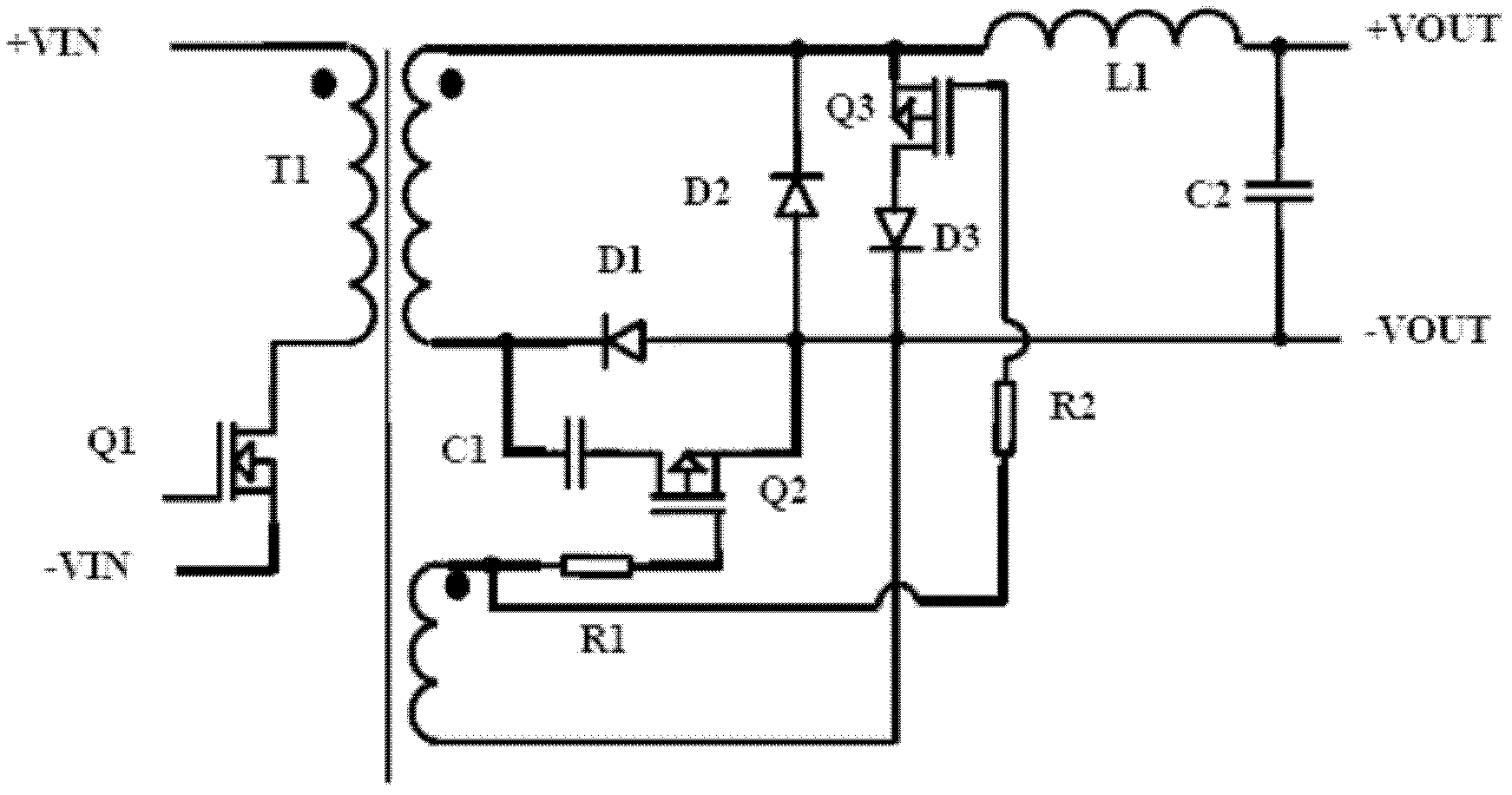

Embodiment 2

[0039] image 3 A specific circuit diagram of a single-ended forward converter provided in this embodiment is shown, as shown in image 3 As shown, in this embodiment, both the clamp transistor Q2 and the discharge transistor Q3 are PMOS transistors.

[0040] image 3 neutralize figure 1 The same components and connection relationship in the above will not be repeated here, and only the components and connection relationship related to the clamping tube Q2 and the discharge tube Q3 will be described.

[0041] The drain of the clamping transistor Q2 is connected to one end of the clamping capacitor C1, and the other end of the clamping capacitor C1 is connected to the cathode of the rectifier D1. Therefore, the drain of the clamping tube Q2 is connected to the opposite end of the secondary winding of the transformer T.

[0042] The source of the clamping tube Q2 is connected to the anode of the rectifier D1, so the source of the clamping tube Q2 is also connected to the outpu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com