Vehicle tire

A technology for pneumatic tires and vehicles, applied in the field of vehicle pneumatic tires, can solve the problems of reduced tire durability, disconnection, and erosion of cords, etc., and achieves the effects of ensuring retreading capability, improving durability, and good damage protection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

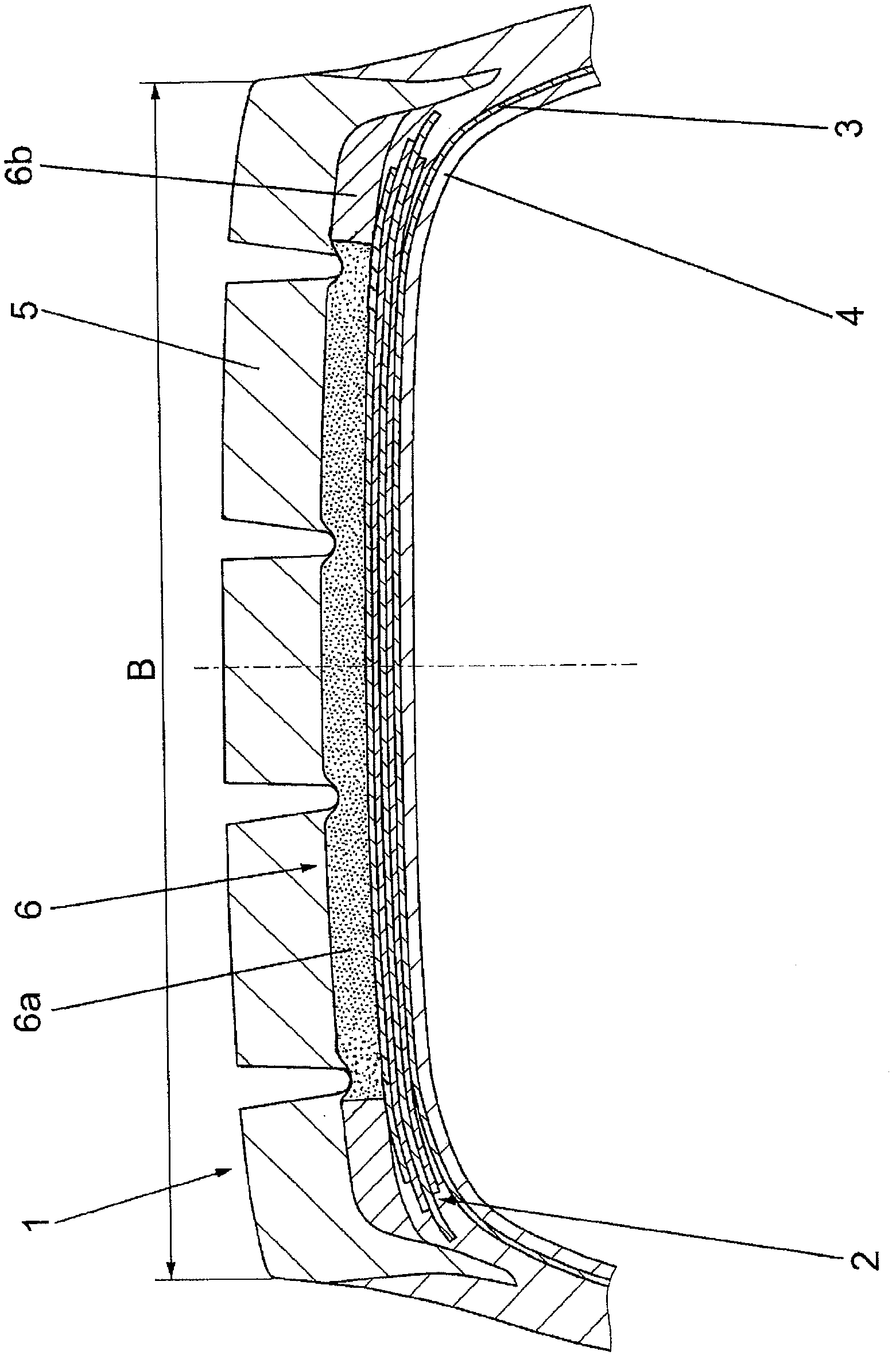

[0025] figure 1 A tread 1 is shown among the usual components of a pneumatic tire for commercial vehicles, one preferably with four cord belt layers 2 consisting of reinforcing fabrics (preferably composed of steel wires) embedded in rubber, one also reinforced with Textile reinforced radial carcass 3 and an airtight inner layer 4 . The figure shows only the axially outer end portion of the sidewall of the tyre. The bead region with bead core and core profile is not shown.

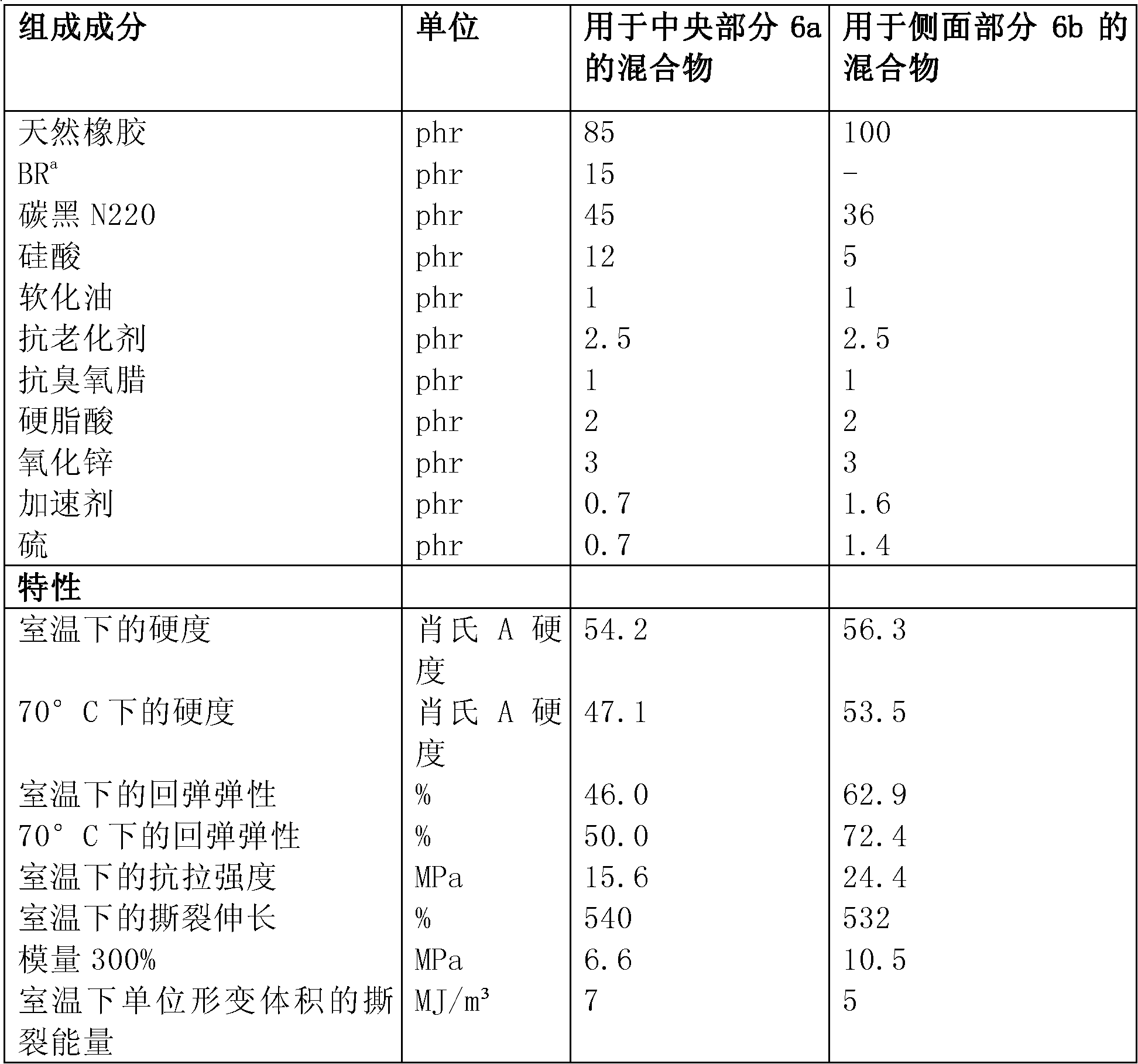

[0026] The tread 1 consists of a radially outer rubber layer (tread cap 5 ) and a radially inner rubber layer (tread base 6 ). A lower plate not shown in the figure may also be arranged under the tread base 6 . The tread base 6 has a substantially constant thickness of about 4.5 mm and is divided into three parts in the axial direction such that it consists of a central part 6a and two side parts 6b. The central part 6a extends centrally relative to the tire center up to the two outer circumferential s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com