NdFeB sintered magnet production method and production device, and NdFeB sintered magnet produced with said production method

A technology of sintered magnets and manufacturing methods, which is applied in the manufacture of inductors/transformers/magnets, magnetic materials, magnetic objects, etc., can solve the problems of demagnetization curve squareness, magnetic properties, material utilization efficiency, and manufacturing costs. Effects of residual magnetic flux density, easy handling, and low-cost manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

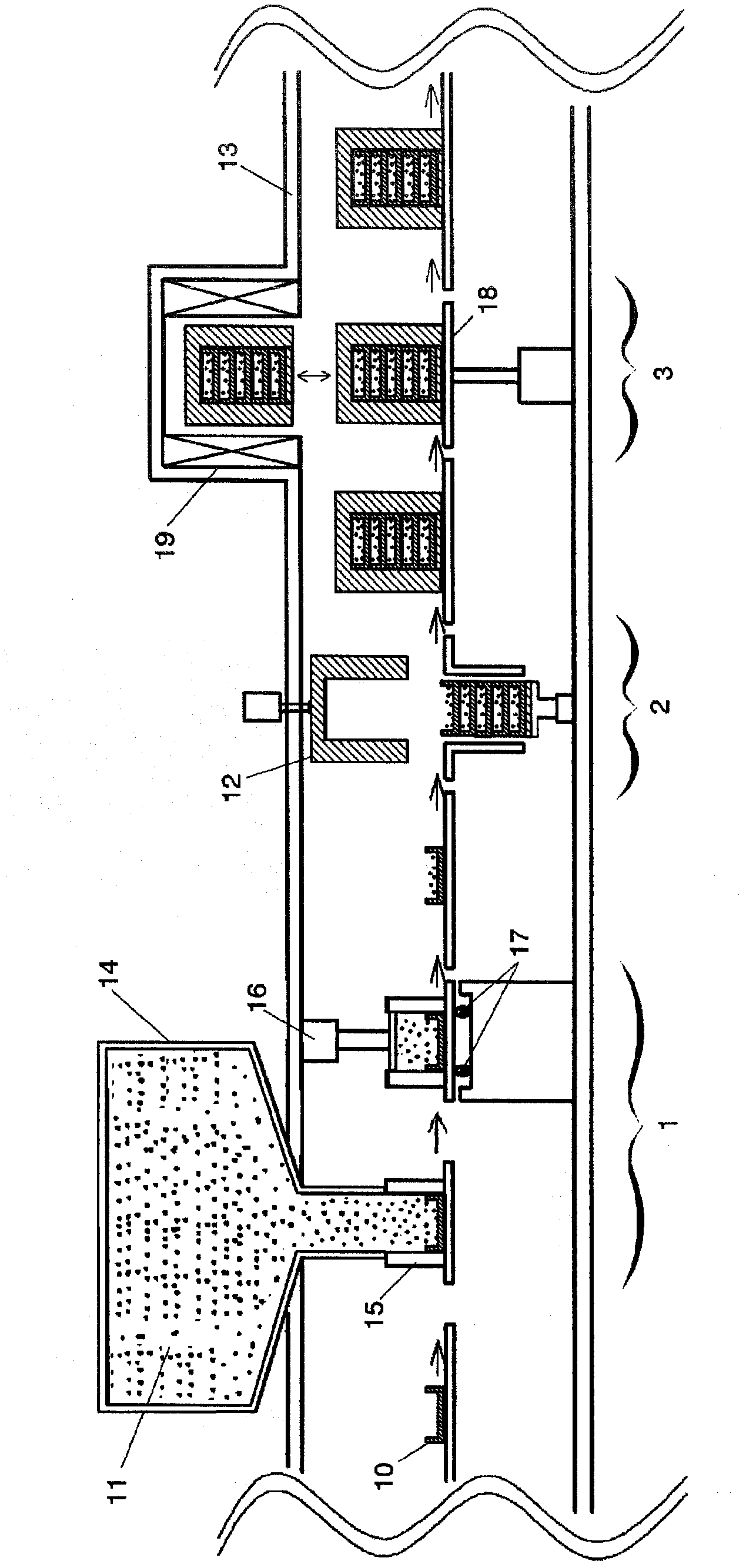

[0067] use Figure 5 and Figure 6 The first embodiment of the manufacturing apparatus of the NdFeB-based sintered magnet of the present invention will be described. The basic structure of the device and figure 1 have the same structure, but differ in that the orientation part 3 is provided with an induction heating coil 20 for heating the alloy powder 11 together with the mold 10 . In the sintered magnet manufacturing apparatus of this embodiment, the mold 10 is inserted inside the induction heating coil 20 , and an electric current is supplied to the induction heating coil 20 to heat the alloy powder 11 together with the mold 10 . Since the induction heating coil 20 is arranged above the conveyance line so that its central axis coincides with the central axis of the magnetic field applying coil 19, heating and magnetic field application can be continuously performed only by moving the elevating platform 18 up and down.

[0068] In addition, the heating method is not limit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com