Flexible capacitive micromachined ultrasonic transducer array with increased effective capacitance

A technology of capacitive micromachining and ultrasonic transducers, applied in piezoelectric devices/electrostrictive devices, circuits, electrical components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

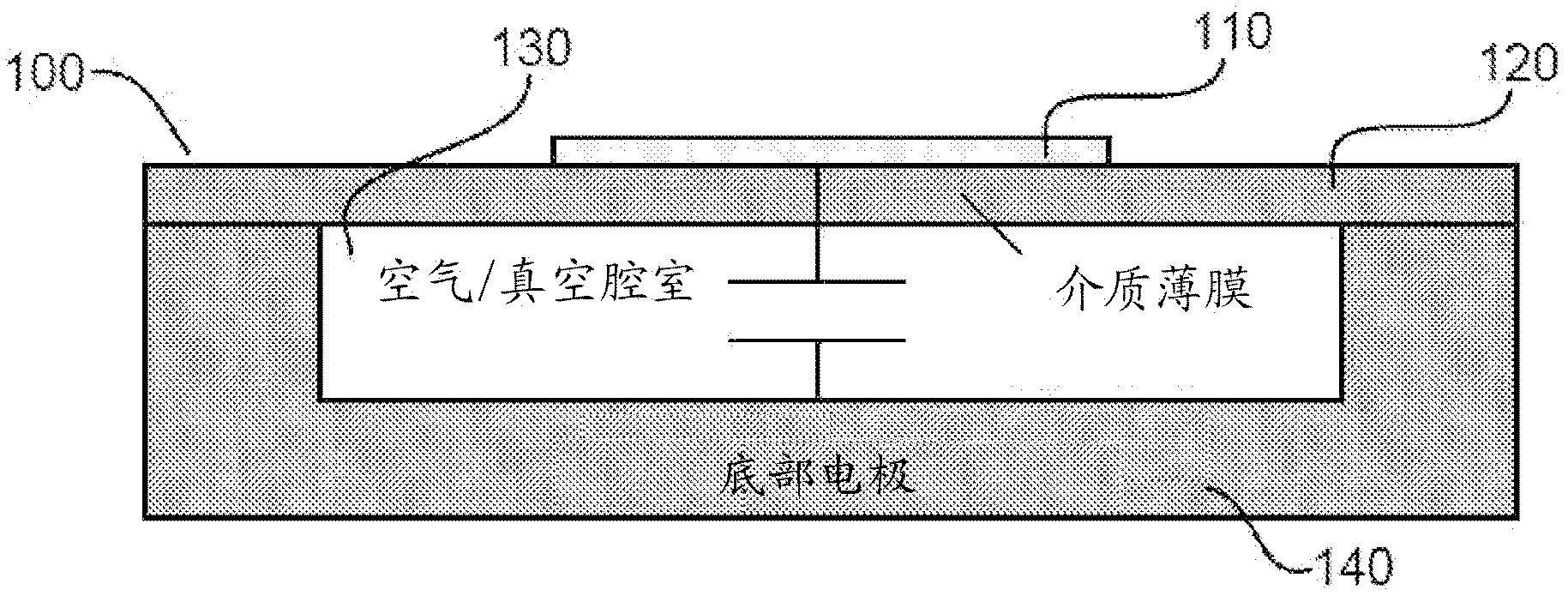

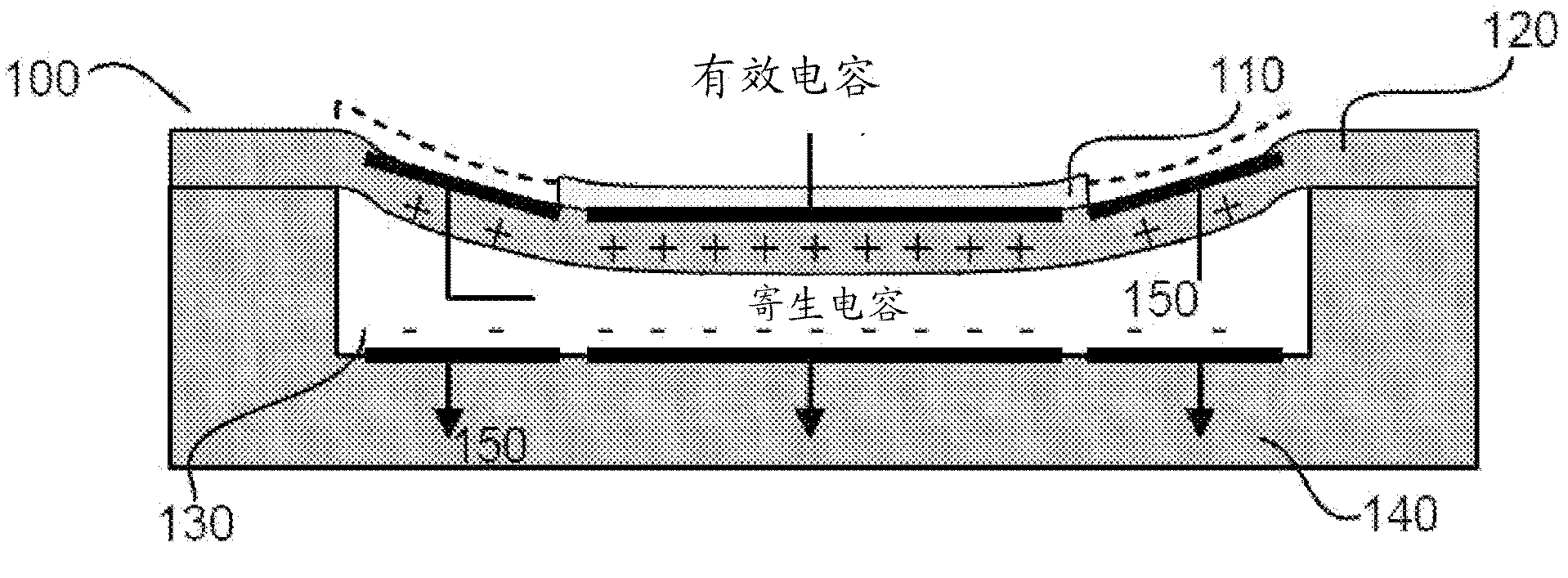

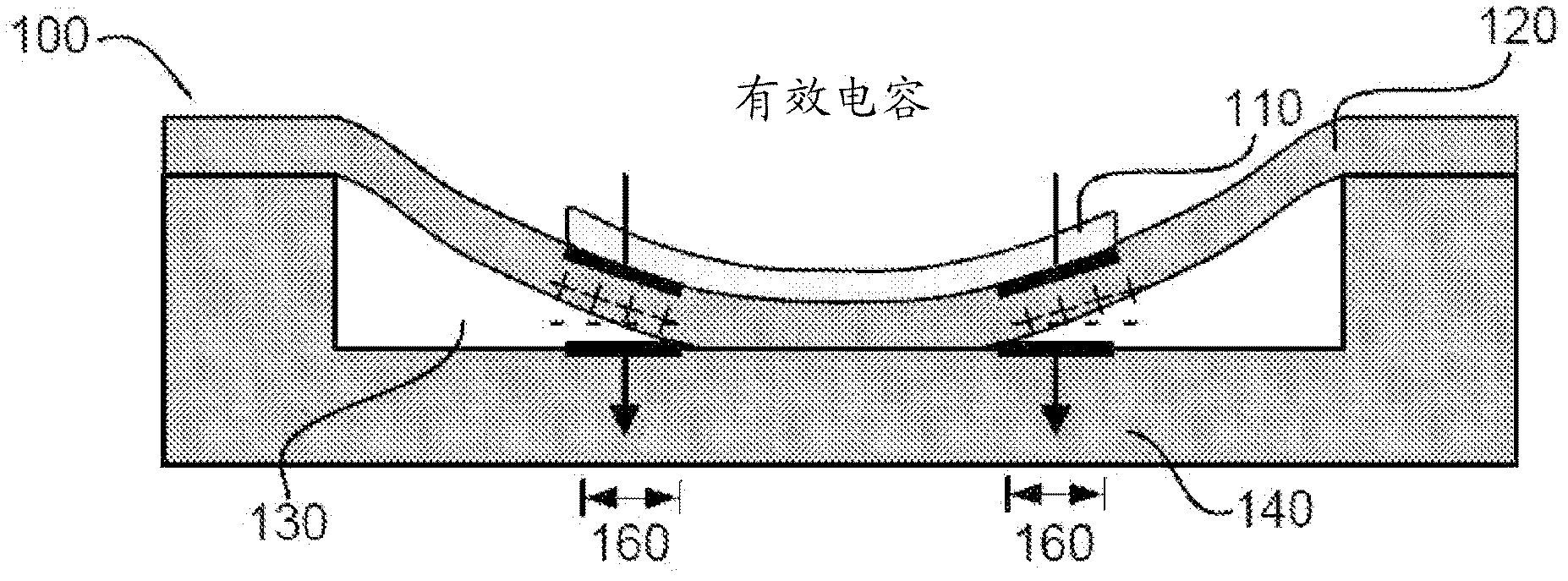

[0053] refer to Figures 8 to 10 , shows a capacitive micromachined ultrasound transducer (CMUT) 200 with a concave shaped bottom electrode 240 . The recessed air chamber 230 is defined by the recess of the bottom electrode 240 . go to Figure 8 , the top electrode 210 covers 100% of the area 260 of the membrane 220 above the air chamber 230 . Therefore, the effective capacitance of CMUT 200 can be significantly higher than figure 1 The effective capacitance of a conventional CMUT (which has a top electrode 110 covering only 25% of the membrane area 120) of .

[0054] go to Figure 9 , the entire area 260 of the membrane 220 above the air chamber 230 is considered to develop an effective capacitance when a direct current (DC) bias is applied. The recess of the bottom electrode 240 substantially matches the deflection of the membrane 220 when a DC bias is applied.

[0055] If the bottom electrode 240 defines a concave shape or curved profile, the membrane 220 can fully f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Young's modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com