Kelp deep-water composite space culture facility and method

A technology of compound space and macroalgae, applied in the fields of botany equipment and methods, seaweed cultivation, horticulture, etc., can solve problems such as environmental conditions, achieve clear light transmittance, increase biomass, and avoid the potential danger of wind and waves.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

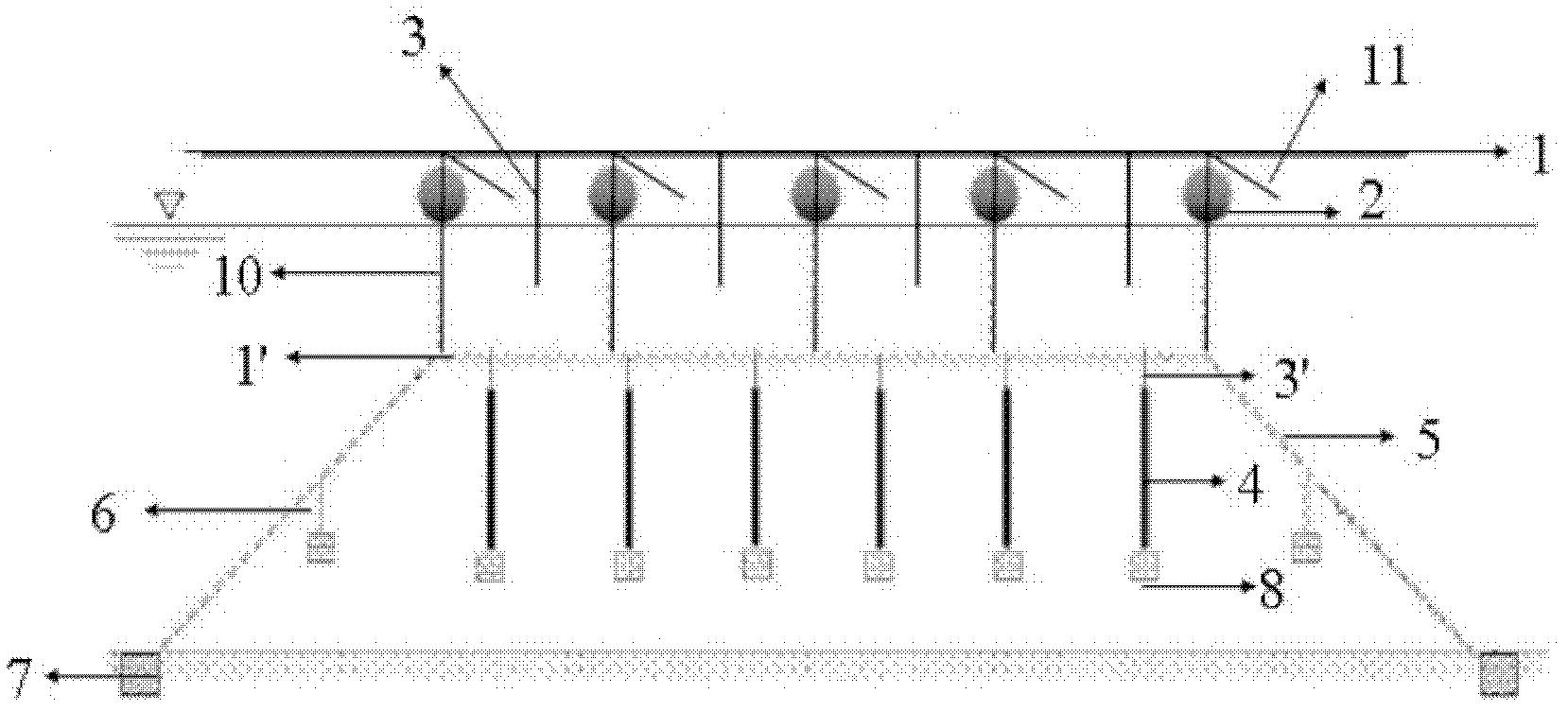

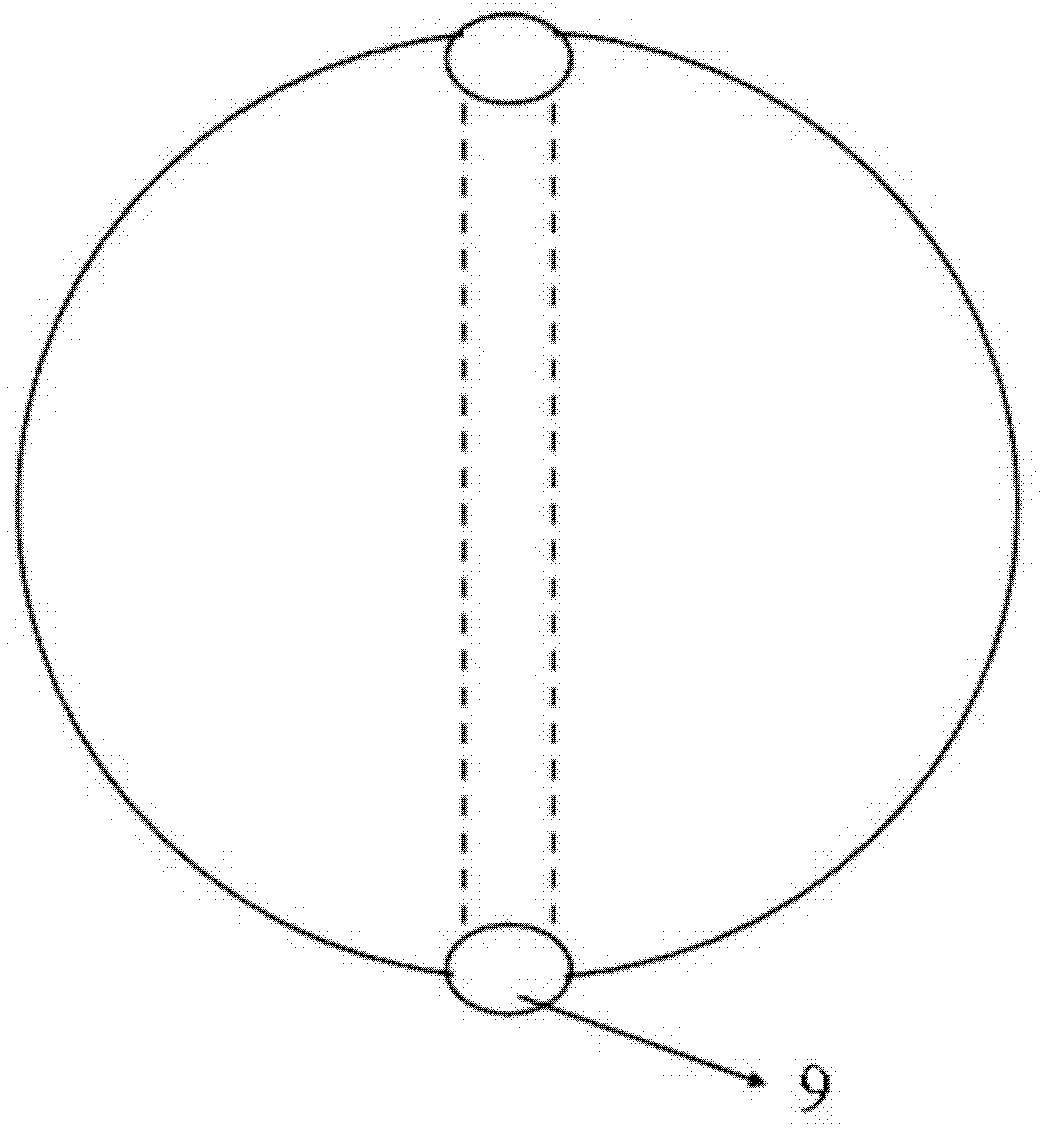

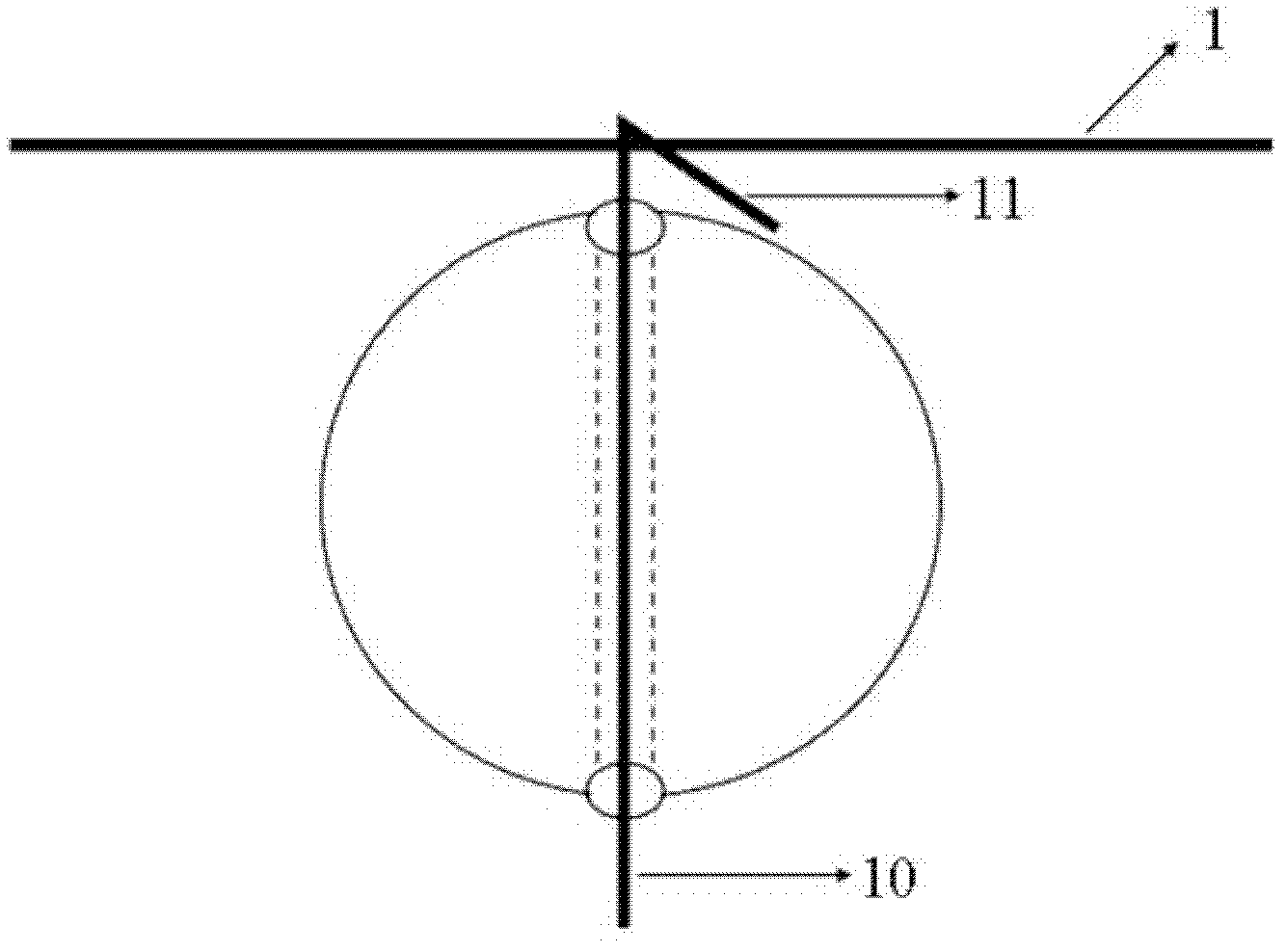

Embodiment 1

[0038] The experiment time is from October 23, 2010 to July 30, 2011. The test site is the sea area of Lidao in Rongcheng City. The water depth of the aquaculture area is 25m, the transparency is 10m, the maximum flow rate is 50cm / s, no industrial and domestic sewage is injected, the annual surface water temperature changes in the range of 3~23℃, the salinity is 28.5~32.1, pH=7.01~9.74, which belongs to the national fishery water quality standard ( I) Class. Use the above-mentioned macroalgae deep-water composite space cultivation facilities and methods for cultivation, such as figure 1 As shown, the surface raft culture device and the middle vertical culture device are each equipped with 50 rows of floats, the spacing between the rows is 4m, and each row has 10 plastic floats2, the float spacing is 3-5m, and the floats 2 With a middle through hole 9, such as figure 2 As shown, the hanging rope on the surface raft culture device is 5-7m long, so that the suspended scallops ...

Embodiment 2

[0042] The experiment time is from October 24, 2010 to July 30, 2011. The test site is the sea area of Zhangzi Island in Dalian. The water depth of the aquaculture area is 30m, the transparency is 11m, the maximum flow rate is 55cm / s, no industrial and domestic sewage is injected, the annual surface water temperature changes in the range of -1.0~24℃, the salinity is 29.5~33, and the pH=7.30~8.30, which belongs to the national fishery water quality standard (I) Class. The cultivation method adopts the above-mentioned macroalgae deep-water composite space cultivation technology. The surface raft-type cultivation device and the middle-layer vertical cultivation device are each equipped with 100 rows of floating nets. The spacing between rows is 3.5m, and each row has 30 plastic floating buckets. The distance between the buckets is 3-5m, and the floating bucket has a central through hole. The hanging rope 3 on the surface raft-type breeding device is 5-7m long, so that the suspe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com