Heater of micro-boiling heat-transfer experimental device

A boiling heat transfer and experimental device technology, applied in laboratory utensils, heating or cooling equipment, chemical instruments and methods, etc., can solve the problems of increasing thermal resistance, thermal insulation material bursting, leakage, etc., to achieve uniform force, eliminate effect of stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The following examples describe the present invention in more detail:

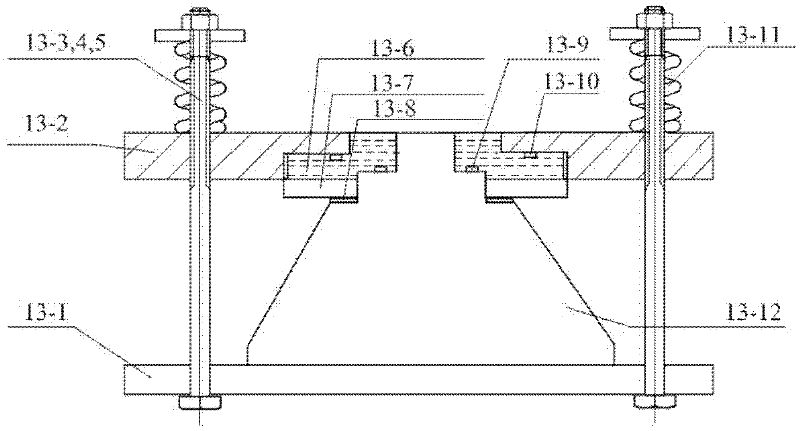

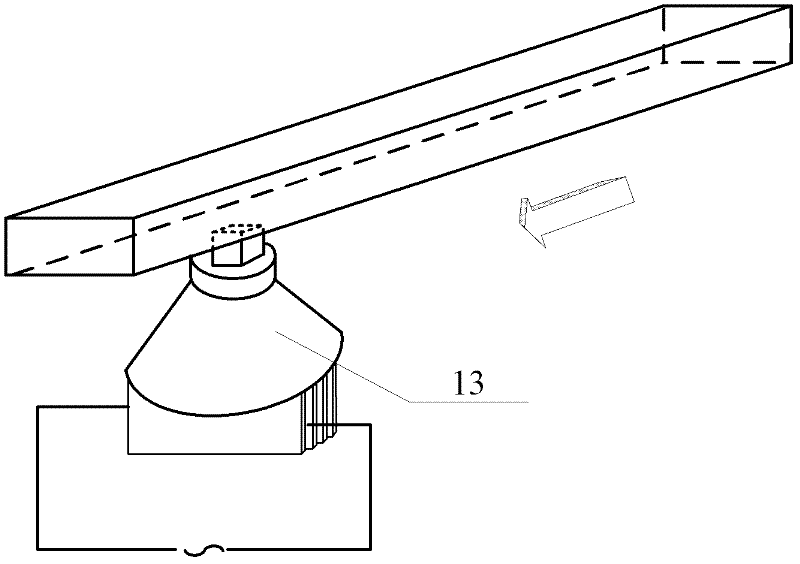

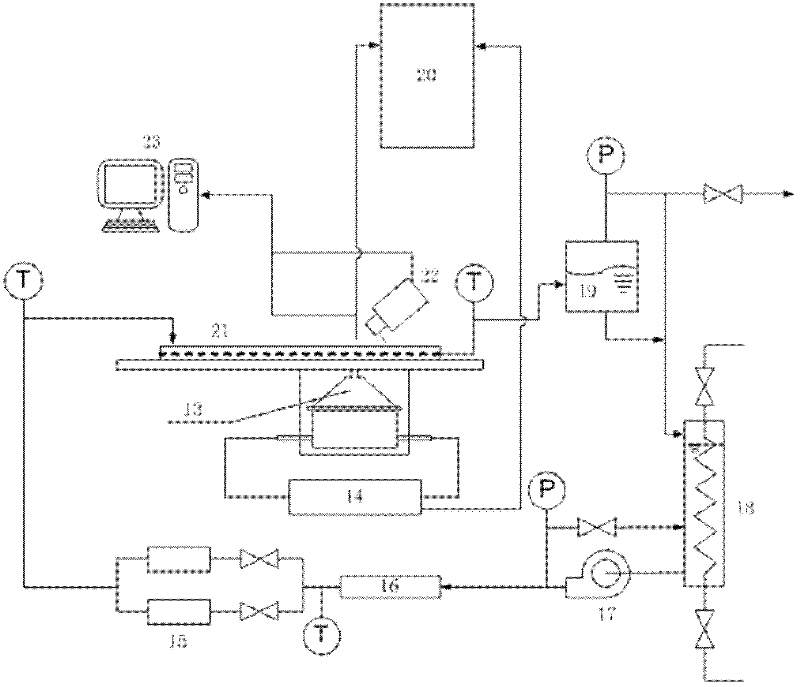

[0017] combine figure 1 , the heater of the miniaturized boiling heat transfer experimental device of the present invention consists of ceramic heat insulating sleeve 13-6, sealing washers 13-9 and 13-10, stainless steel pressure equalizing washers 13-7, cover plate 13-1 and fastening bolts 13-11 and so on constitute. The fixing between the cover plate 13-1 and the test section shell 13-2 is realized by fastening bolts. The cover plate and the heating copper block 13-12 are close together, and the top of the heating copper block 13-12 is processed with a step. Heat insulating gasket 13-8 and stainless steel pressure equalizing washer 13-7 are respectively installed, between the stainless steel pressure equalizing washer and the shell of the test section is ceramic heat insulating sleeve 13-6, heating copper block 13-12 and heat insulating sleeve 13- There is a seal ring 13-9 between the 6, a seal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com