Vortex type grinding machine

A grinding machine and eddy current technology, applied in the field of machinery, can solve the problems of injury to operators, manual support, inconvenient operation, etc., and achieve the effects of high utilization rate of consumables, balanced operation and beautiful appearance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

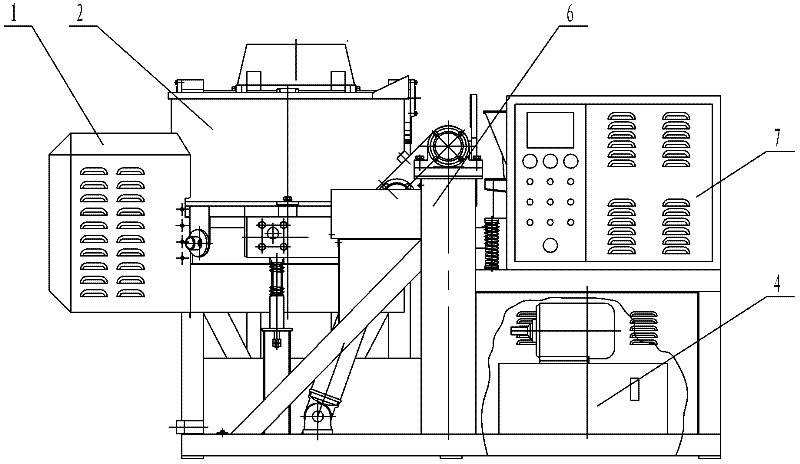

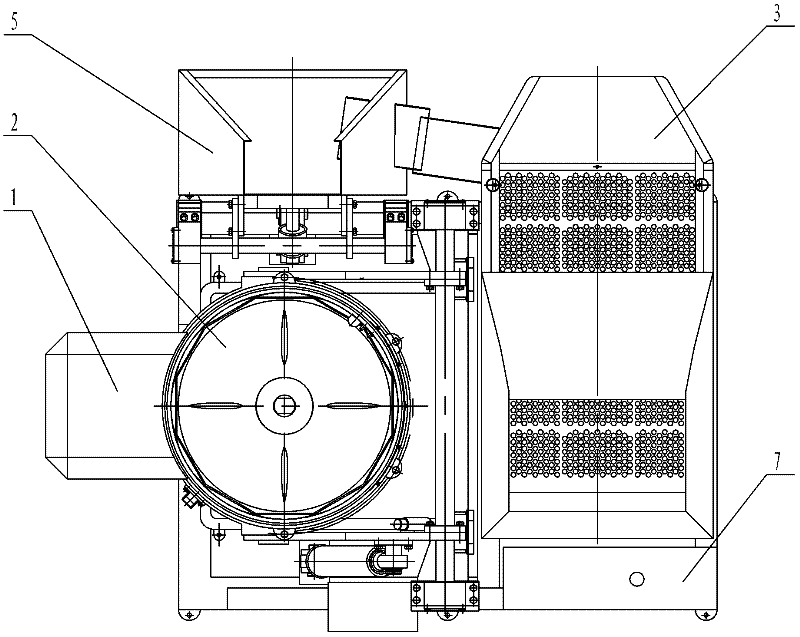

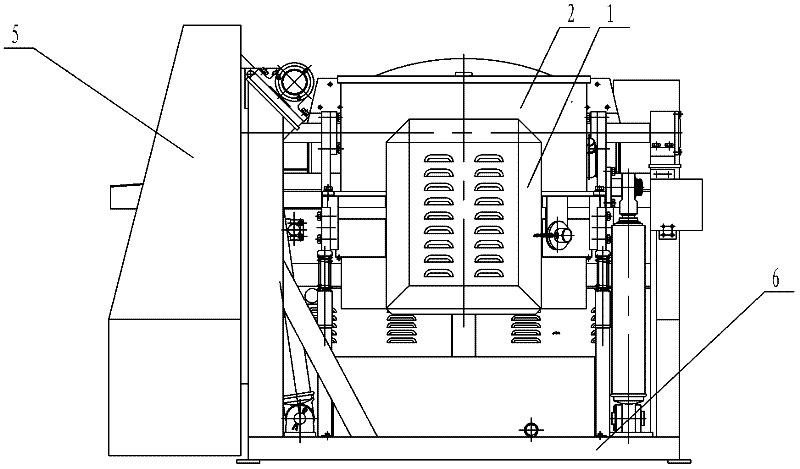

[0029] The present invention will be further described below in conjunction with specific drawings.

[0030] Such as Figure 1 to Figure 12 Shown: The eddy current grinding machine includes motor cover 1, grinding mechanism 2, sorting mechanism 3, hydraulic tank 4, feeding mechanism 5, base 6, electrical box 7, grinding tank 8, fixed disc 9, turning shaft 10, return Turntable 11, slewing sleeve 12, large pulley 13, motor pulley 14, three-phase asynchronous motor 15, overturn cylinder 16, wear-resistant layer 17, rotary shaft 18, motor fixing plate 19, rotary drum 20, shaft cover 21, the first Axle sleeve 22, first bearing 23, second bearing 24, second axle sleeve 25, third axle sleeve 26, seal ring 27, flip lever 28, bearing seat 29, cylinder seat 30, bearing seat 31, upper hopper 32, Hopper shaft 33, hopper outlet 34, feeding cylinder 35, cylinder upper seat 36, cylinder lower seat 37, support rod 38, receiving hopper 39, vibrating screen upper part 40, vibrating screen lowe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com