Planar maglev linear-motion platform

A linear motion, planar technology, applied in the direction of the workbench, manufacturing tools, etc., can solve the problem of limited planar motion travel, achieve the effect of large planar travel range, high dynamic response performance and motion accuracy, and avoid crawling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

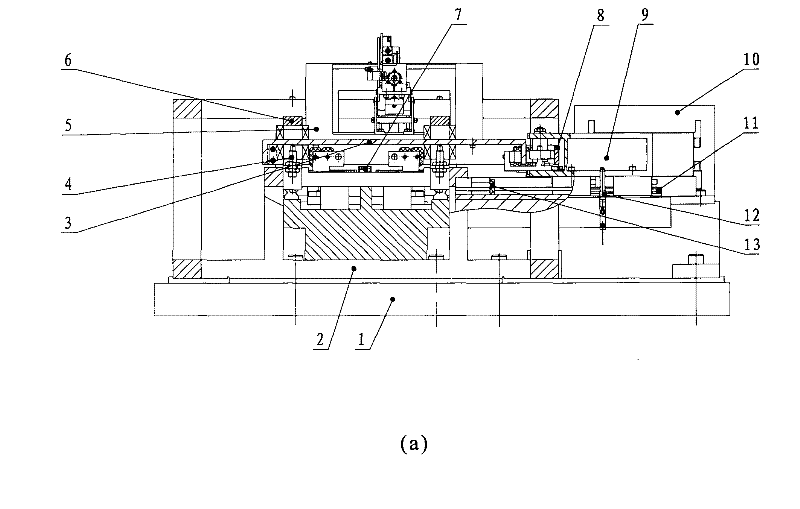

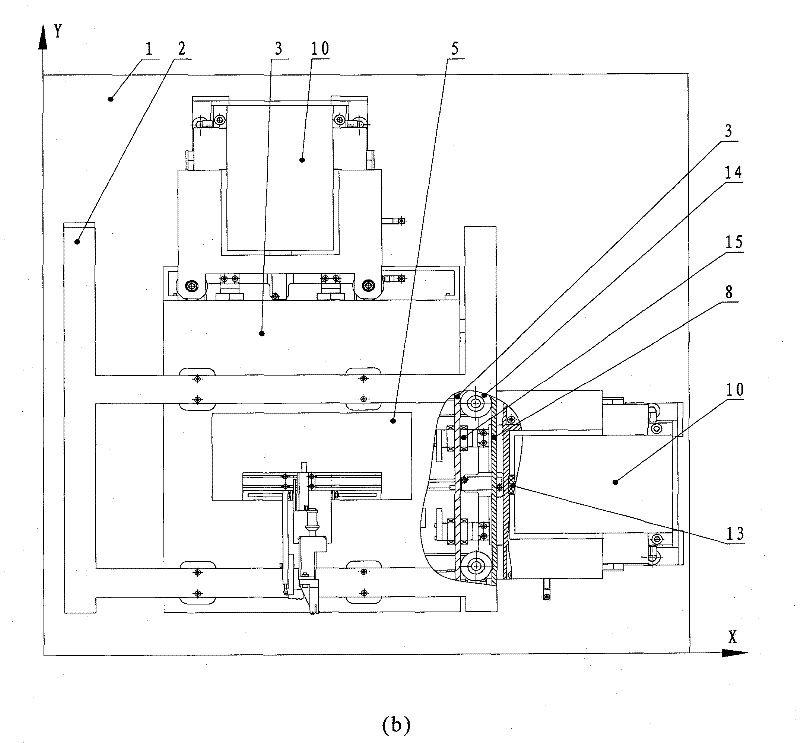

[0011] see figure 1 , the planar maglev linear motion platform of the present invention, the main components include: a base (1), an electromagnet bracket (2) (supporting four pairs of vertical electromagnets), a maglev working platform (3), four sets of vertical Eddy current sensor (4), working load (5), four pairs of differential drive electromagnets (6), two sets of linear encoders for detecting motor displacement (7), positioning plate (8), drive bracket (9) , vertically place two linear motors (10) that move in the XY direction respectively, two pairs of parallel guide rails (11) that are consistent with the direction of motion of the motors, a photoelectric switch (12), and a limit block (13). Two pairs of rolling bearings (14) and two pairs of horizontal guiding electromagnets (15) are respectively arranged on each guiding direction. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com