Ballastless track plate prefabricating pedestal

A technology of ballastless track and prefabricated table, which is applied in the direction of manufacturing tools, auxiliary molding equipment, ceramic molding machines, etc., can solve the problems of large amount of reinforced concrete and other materials, complicated construction, and long cycle, so as to save the number of configurations and adapt to the Strong, reasonable design effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

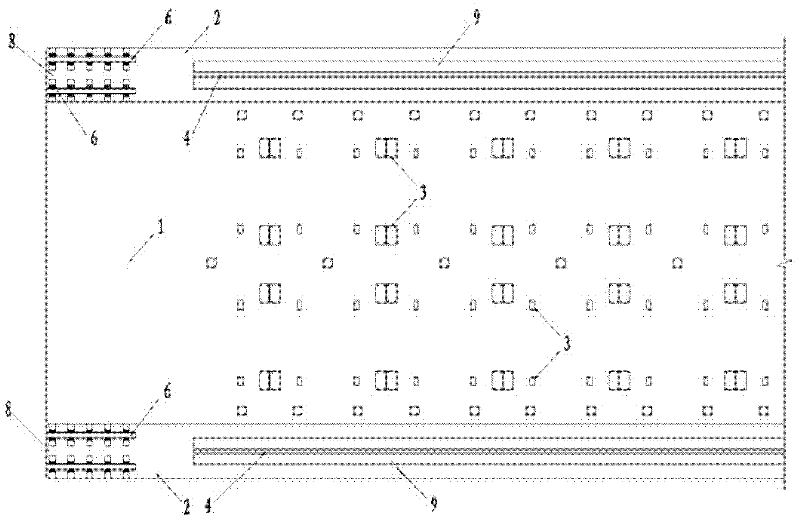

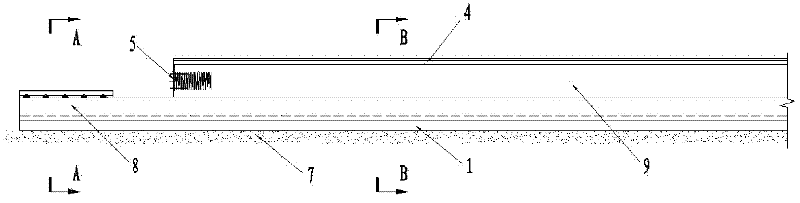

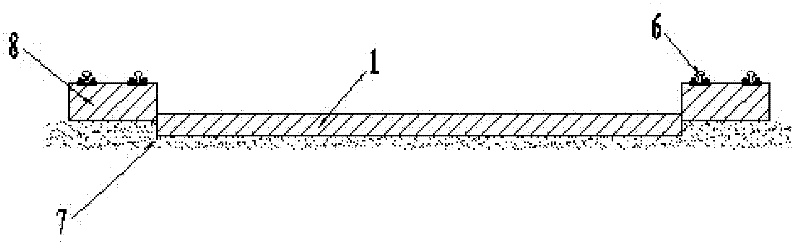

[0019] The preferred embodiment of the ballastless track slab prefabricated base of the present invention is as follows: Figure 1 to Figure 6 Shown:

[0020] It includes a base plate 1 with a rectangular top surface. The two sides of the base plate 1 are respectively provided with a reaction wall 2. The base plate 1 and the reaction wall 2 are split structures. There are several A ballastless track slab template embedded part 3, the ballastless track slab template embedded part 3 is exposed above the top surface of the ground plate 1;

[0021] The reaction wall 2 includes an end reaction wall 8 and a middle reaction wall 9, the end reaction wall 8 has a rectangular cross section, the middle reaction wall 9 has an inverted T-shaped cross section, and the middle The reaction wall 9 is higher than the end section reaction wall 8;

[0022] The middle section reaction wall 9 is provided with a rail 4, and the rail 4 is partly exposed above the top surface of the middle section r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com