Near-field electrostatic jet-printing head

A near-field electrostatic and printing head technology, applied in printing and other directions, can solve the problems of low positioning accuracy, high driving voltage, platform movement speed/acceleration deposition failure, etc., achieve high positioning accuracy, low driving voltage, and reduce spraying voltage The effect of the threshold

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

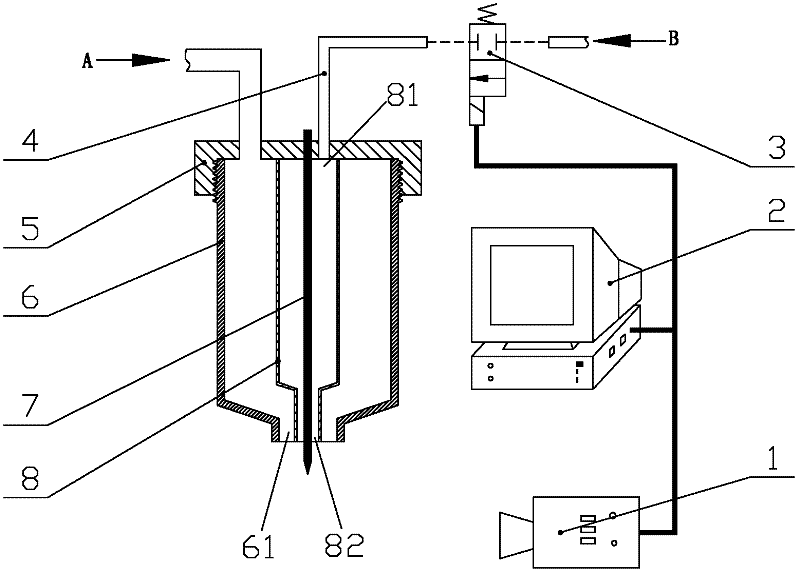

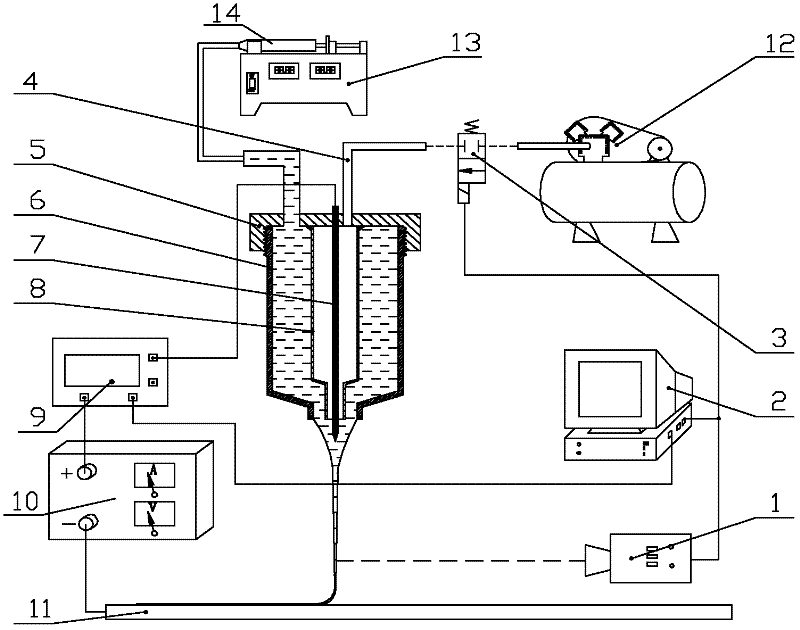

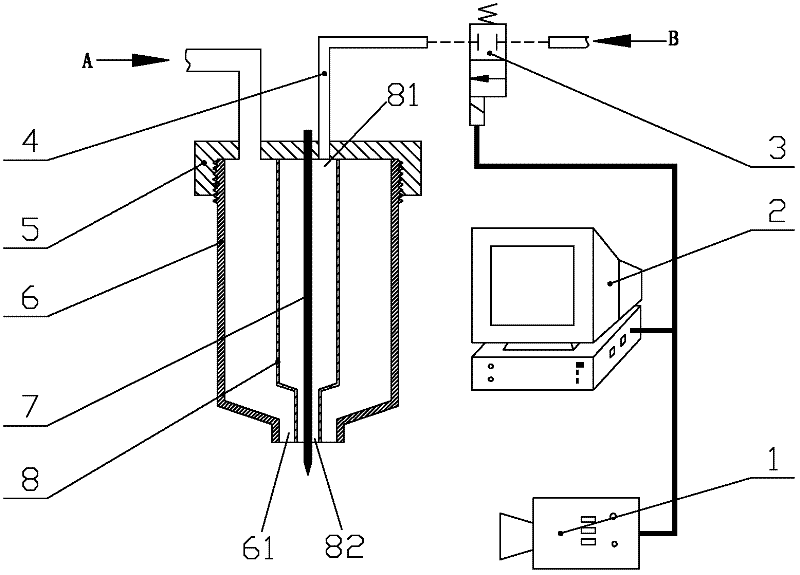

[0024] join figure 1 and figure 2 , The embodiment of the present invention is equipped with a laser generator 1, a computer 2, a solenoid valve 3, an air guide tube 4, a sealing head 5, a nozzle tube 6, a conductive probe 7 and an air tube 8. The laser generator 1 can generate a high-temperature laser beam, irradiate the jet to instantly vaporize the jet, and cut off the jet printing, which can improve the positioning accuracy and structural size accuracy when the printing is stopped; the computer 2 is connected with the laser generator 1 and the solenoid valve 3, and uses It is used to control the switch of the laser generator 1 and the solenoid valve 3; the solenoid valve 3 is used to control the flow of high-pressure gas A; the nozzle 6 is an insulating hollow tube for placing the solution, the upper end has an external thread, and the lower end is a nozzle ;The head 4 is connected to the upper end of the nozzle through the internal thread to prevent the solution from ov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com