Balance shaft assembly

A balance shaft and assembly technology, which is applied in the field of vehicles and engineering, can solve problems such as high cost, poor processing technology, and insufficient carrying capacity, and achieve the effect of low cost, compact structure, and improved carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

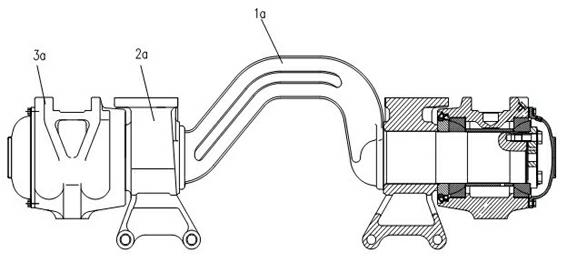

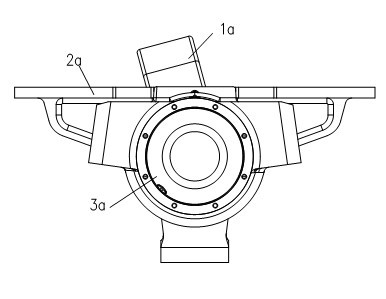

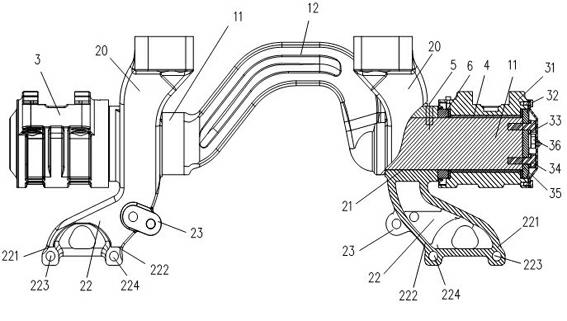

[0026] like image 3 , Figure 4 As shown, the balance shaft assembly of the present invention includes a balance shaft 1, a bracket 2, a bearing hub assembly 3 and a bushing 4; wherein the balance shaft 1 is vertically arranged and connected with the bracket 2 through a positioning pin 5, and the bearing hub assembly 3 is connected to the The balance shafts 1 are connected by a sliding fit through bushings 4 . The specific structure is further detailed as follows:

[0027] The balance shaft 1 has support parts 11 at both ends and an eccentric part 12 formed by bending to one side in the middle; four bolt holes 111 are provided in the axial direction of the support parts 11 at both ends, and a positioning hole 112 is provided in the radial direction; the balance shaft 1. The bearing part adopts intermediate frequency surface quenching.

[0028] The brackets 2 are a pair of symmetrical arrangements, respectively supporting the support parts 11 at both ends of the balance sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com