Paper folding roll structure for folding machine for boxed extraction type paper towels

A folding machine and paper roller technology, applied in the field of origami roller structure, can solve the problems of low work efficiency, affecting the quality of processing and finished products, low paper folding precision, etc., to reduce energy consumption and operating costs, realize automatic operation, and paper folding precision. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

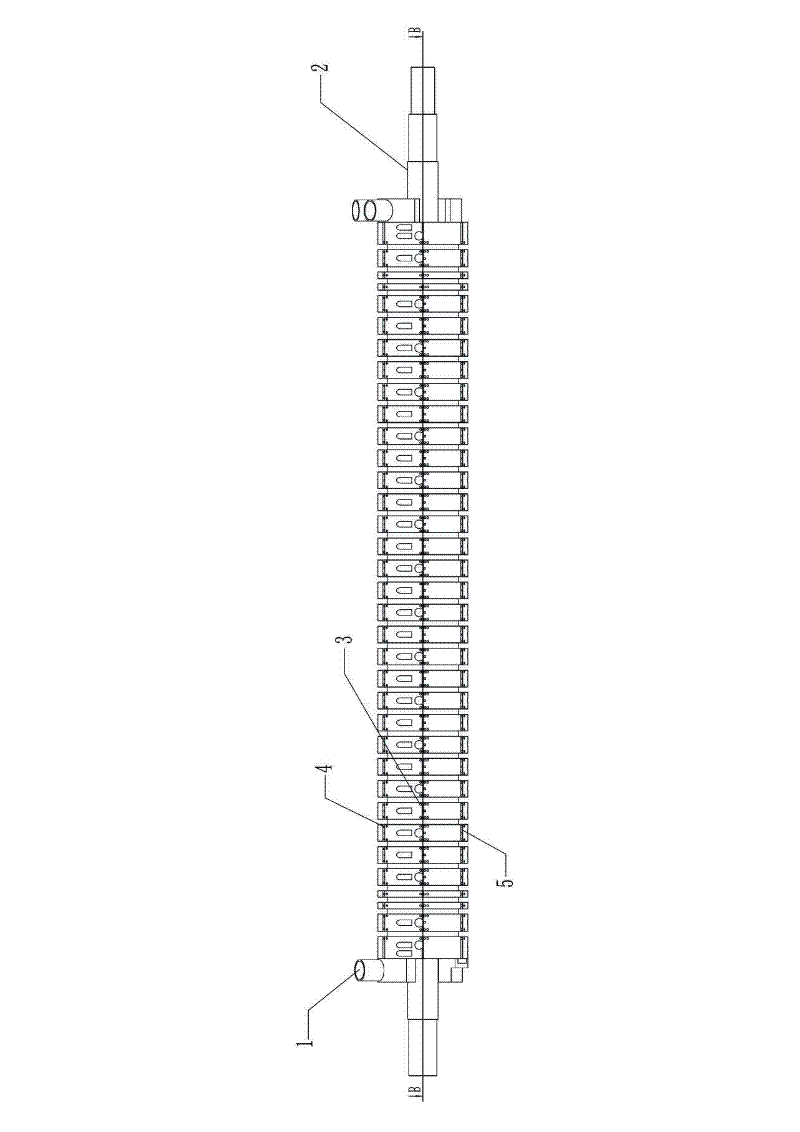

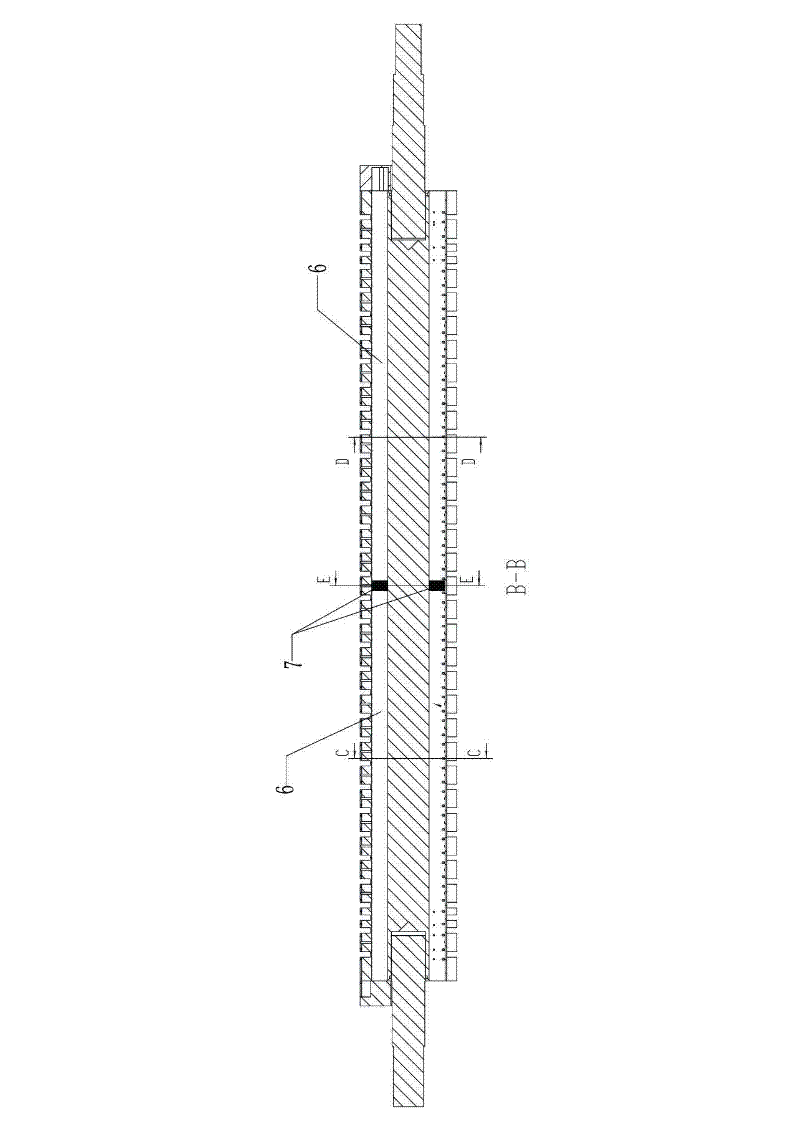

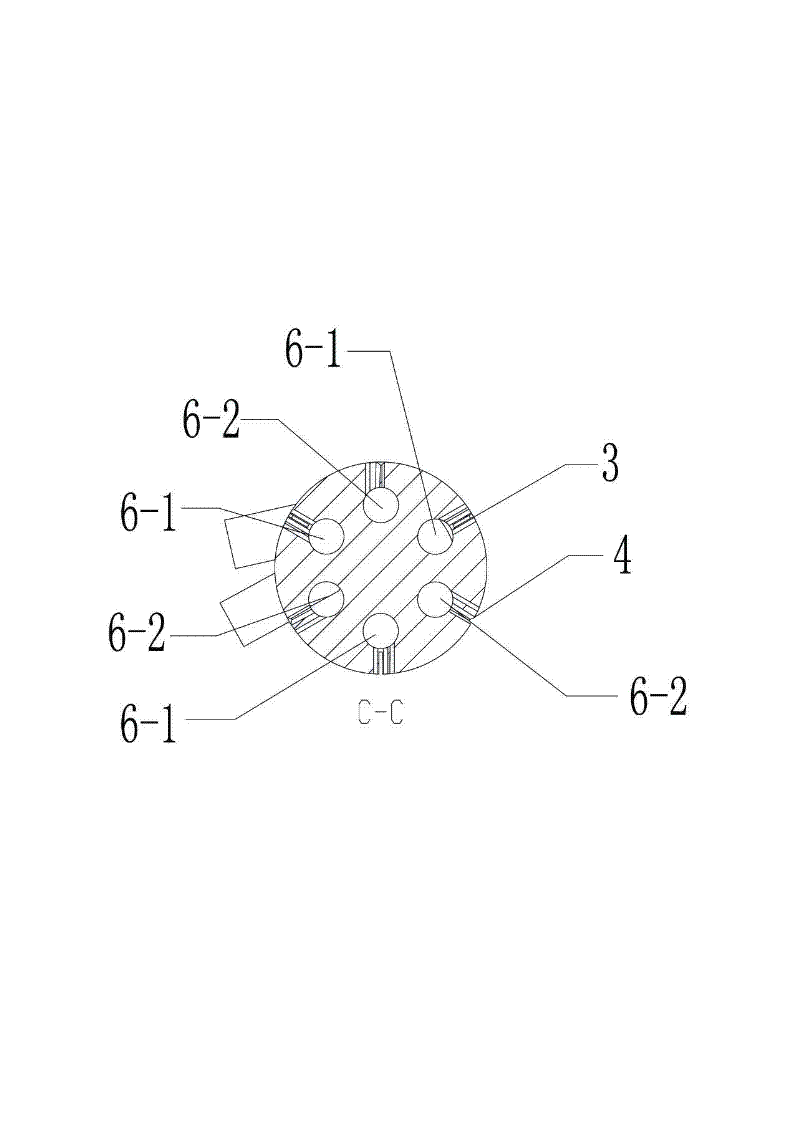

[0026] Embodiment 1: according to the appended figure 1 to attach Figure 5 As shown, the folding roll structure used on the box-pumping tissue folding machine described in this embodiment includes a folding roll body 2 with suction control ports 1 at both ends, wherein the suction control ports 1 of this embodiment It can be arranged on both ends of the folding roller body 2 or on both ends of the roller surface, or on both ends of the folding roller body 2 and on both ends of the roller surface. The vacuum equipment is connected, and the other end forms a periodic cooperation with the airflow passage 6 of the rotating folding roller body 2. During operation, the rotation of the folding paper roller body 2 makes each section of the airflow passage 6 form a periodicity with the respective suction control port 1. Connect the suction, that is, when the airflow channel 6 of the origami roller body 2 is turned to communicate with the suction control port 1, the vacuuming equipmen...

Embodiment 2

[0027] Embodiment 2: According to the attached figure 1 to attach figure 2 And attached Figure 6 to attach Figure 8 As shown, the difference from Example 1 is that the paper-feeding airflow channel and the folding paper suction airflow channel of this embodiment are the same airflow channel 8, therefore, there are three airflow channels 8 in this embodiment, and the corresponding airflow channel of this embodiment Both the paper feeding suction hole 3 and the folding paper suction hole 4 communicate with the same airflow channel 8 .

Embodiment 3

[0028] Embodiment 3: according to the appended Figure 9 to attach Figure 10 And attached Figure 11 to attach Figure 13 As shown, the difference from Embodiment 1 is that the folding groove 5 is not provided on the roller surface of the folding roller body 2 of this embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com