Fixed seat of yarn-unwinding tube on cord-knitted winding machine with knotless net

A technology of winding machine and yarn bobbin, which is applied in the direction of conveying filamentous materials, thin material processing, transportation and packaging, etc., can solve the problems that the bobbin cannot be too long and cannot be used, and achieves convenient production, low cost, Practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

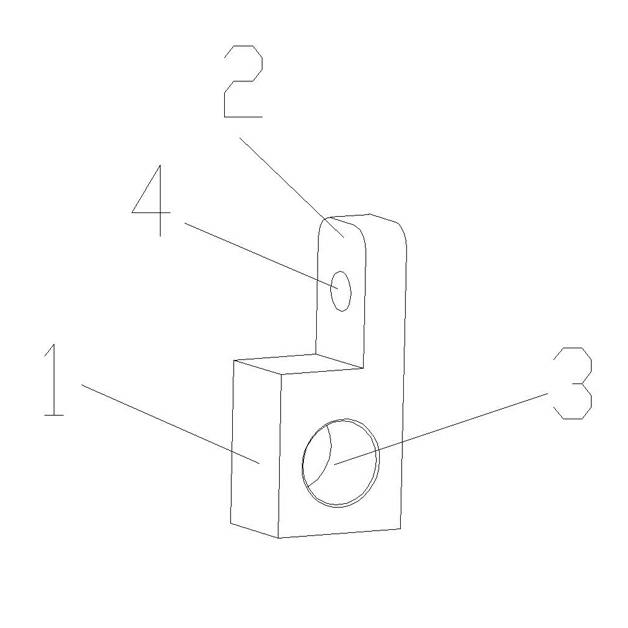

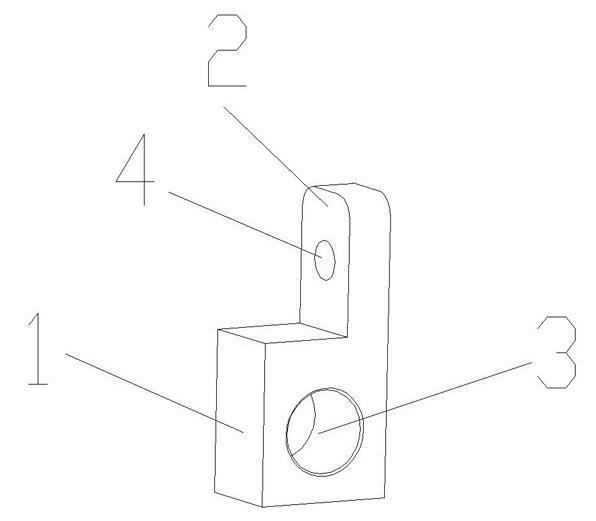

[0011] Such as figure 1 The lower bobbin fixing seat on a rope knitting knotless net winding machine shown includes a body, and the body includes a first body 1 and a second body 2; the top of the first body 1 is vertically provided with a second body The body 2, and the thickness of the second body 2 is one-third of the thickness of the first body 1; the first body 1 is provided with a first through hole 3; the second body 2 is provided with a second through hole 4. The first body 1 and the second body 2 are integrally manufactured. The first through hole 3 and the second through hole 4 are perpendicular to each other in the direction of their centerlines. The lower bobbin fixing seat on the rope knitting knotless net winding machine of the present embodiment is an important part on the rope knitting knotless net winding machine. The utility model has the characteristics of convenient manufacture, low cost and strong practicability.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com