Method and device for online optimized control of operation of two-sludge denitrifying dephosphatation process

A technology for denitrification, phosphorus removal, and process operation, which is applied in the field of on-line optimization control methods and devices, can solve the problems of incomplete denitrification reaction, large fluctuation of influent water quality, unstable system operation, etc. Cost doubling, avoiding high operating costs, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

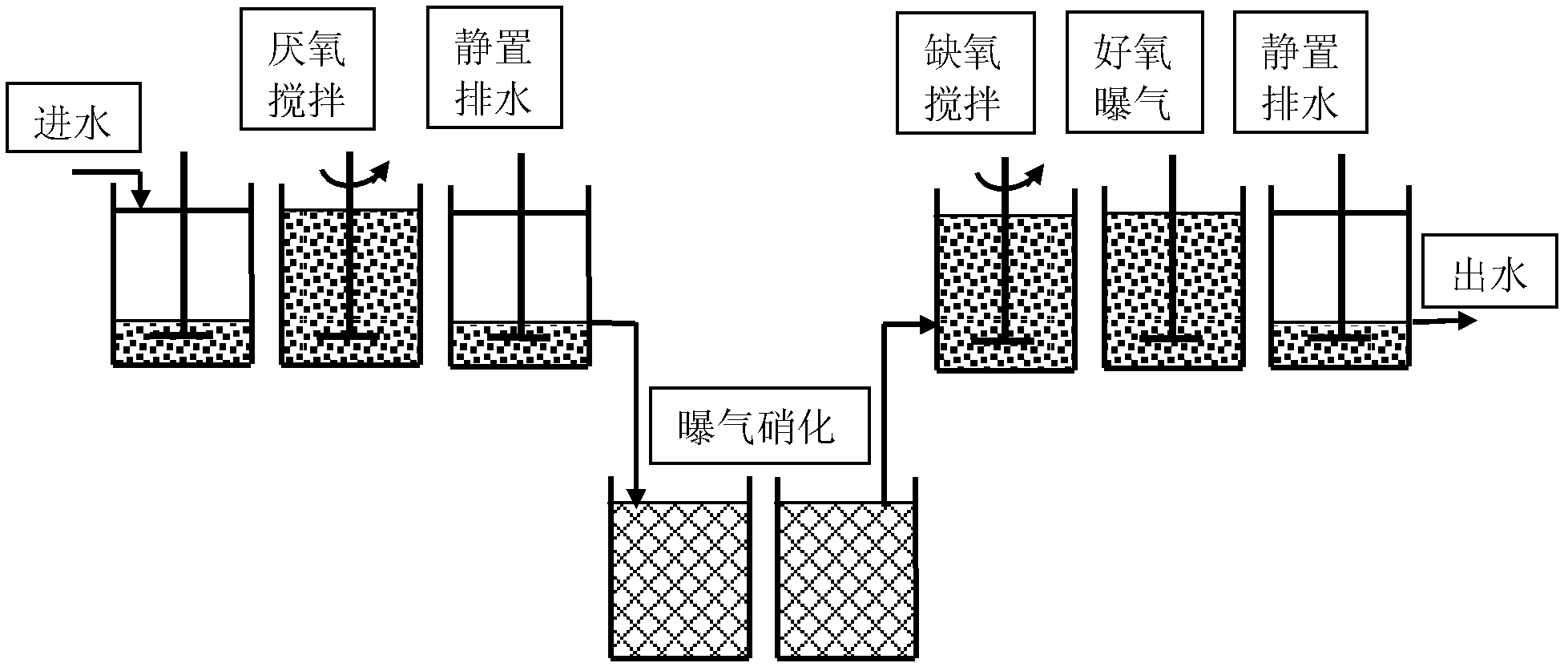

[0038] The operation procedure of double sludge denitrification phosphorus removal process is as follows: figure 1 As shown, the entire system is controlled by a real-time control system, and the twelve processes of water intake, anaerobic stirring, sedimentation, drainage, nitrification aeration, sedimentation, reflux, anoxic stirring, post-aeration, sedimentation, drainage, and idleness are repeated in sequence. . Firstly, water enters the anaerobic / anoxic reaction tank, and the activated sludge undergoes anaerobic phosphorus release reaction. After sedimentation, the supernatant is drained to the aerobic biofilm nitrification reaction tank by gravity flow. After a period of aerobic nitrification aeration reaction and rapid precipitation, the digestive liquid is returned to the anaerobic / anoxic reaction tank through the reflux pump, and enters the stage of anoxic and subsequent aerobic aeration. Before the end of each cycle, the remaining activated sludge is discharged from...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com