Paraffin-based rubber softening oil and preparation method thereof

A rubber softening oil, paraffin-based technology, applied in the chemical industry, can solve the problems of not meeting environmental protection requirements, poor compatibility, high volatility, etc., and achieve excellent compatibility, low volatility, and good oxidation resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

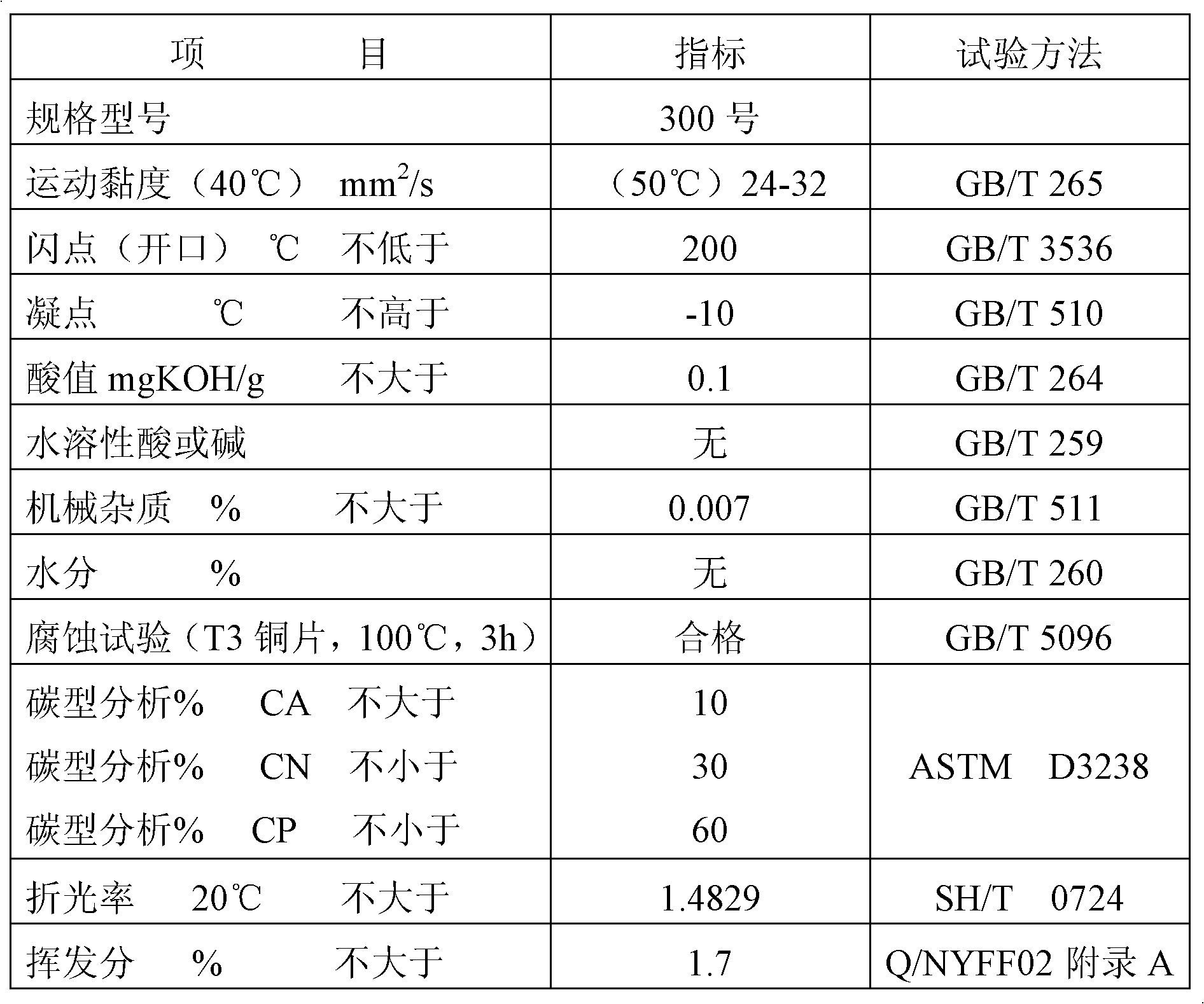

Method used

Image

Examples

Embodiment 1

[0058] Use paraffin base oil as the base oil. During the production process, first add 65kg of paraffin base oil into the reaction kettle, heat to 65±5°C and stir, then add 33kg of liquid paraffin wax and 2kg of anti-aging complexing agent in turn, and stir each After 25-35 minutes a paraffin-based rubber softening oil is obtained.

Embodiment 2

[0060] Using paraffinic base oil as the base oil, in the production process, first add 72kg of paraffinic base oil into the reaction kettle, add 27kg of liquid paraffin paraffin and 1kg of anti-aging complexing agent in turn after heating, and stir for 25-35 minutes to obtain Paraffin-based rubber softening oil.

Embodiment 3

[0062] Using paraffinic base oil as the base oil, in the production process, first add 68kg of paraffinic base oil into the reaction kettle, add 28kg of liquid paraffin and 4kg of anti-aging complexing agent in turn after heating, and stir for 25-35 minutes to obtain paraffin Base rubber softening oil.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com