Priming-finishing integrated rust protection paint

A technology of anti-rust paint and bottom surface, applied in the field of coatings, can solve the problems of unreachable anti-rust paint and thick coating layer, and achieve the effect of good anti-rust performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

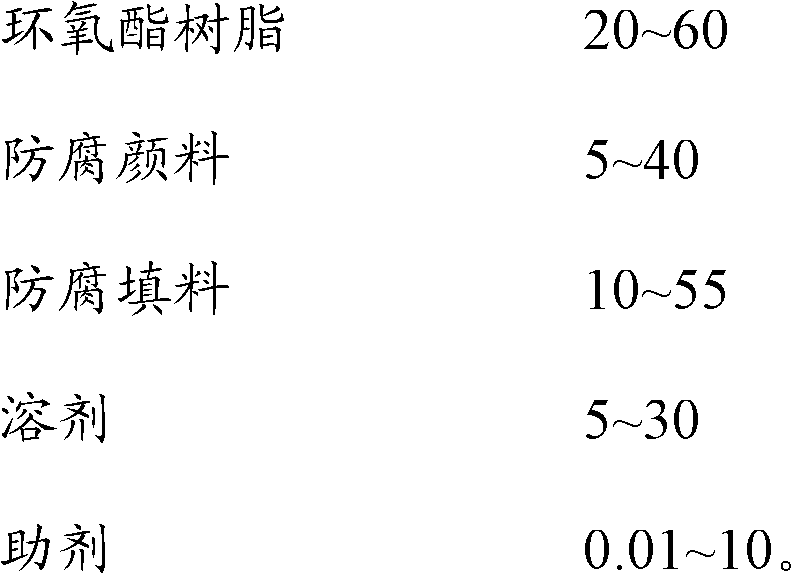

[0045] According to the following composition proportions, the antirust paint combined with bottom and surface is prepared, and its composition is according to parts by weight:

[0046]

[0047]

Embodiment 2

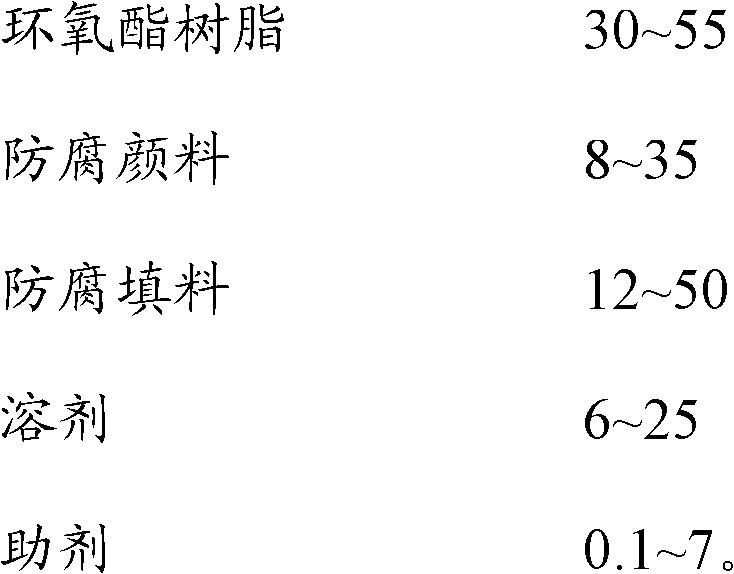

[0049] According to the following composition proportions, the antirust paint combined with bottom and surface is prepared, and its composition is according to parts by weight:

[0050]

Embodiment 3

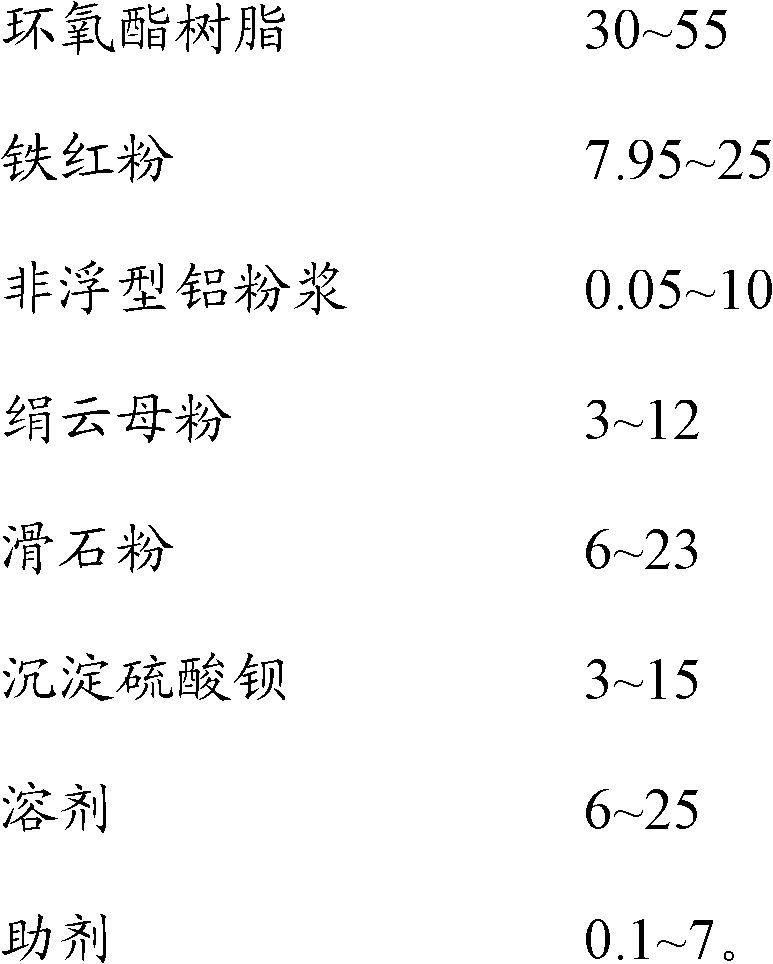

[0052] According to the following composition proportions, the antirust paint combined with bottom and surface is prepared, and its composition is according to parts by weight:

[0053]

[0054]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com