Production method for fine denier bright triangular profiled fiber

A special-shaped fiber, production method technology, applied in fiber processing, textile and papermaking, filament/thread forming, etc., can solve the problems of not very bright fabric flash effect, triangular special-shaped fiber is not very high, etc., to optimize spinning Process parameters, enhancing market competitiveness, and reducing power consumption per ton of wire

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

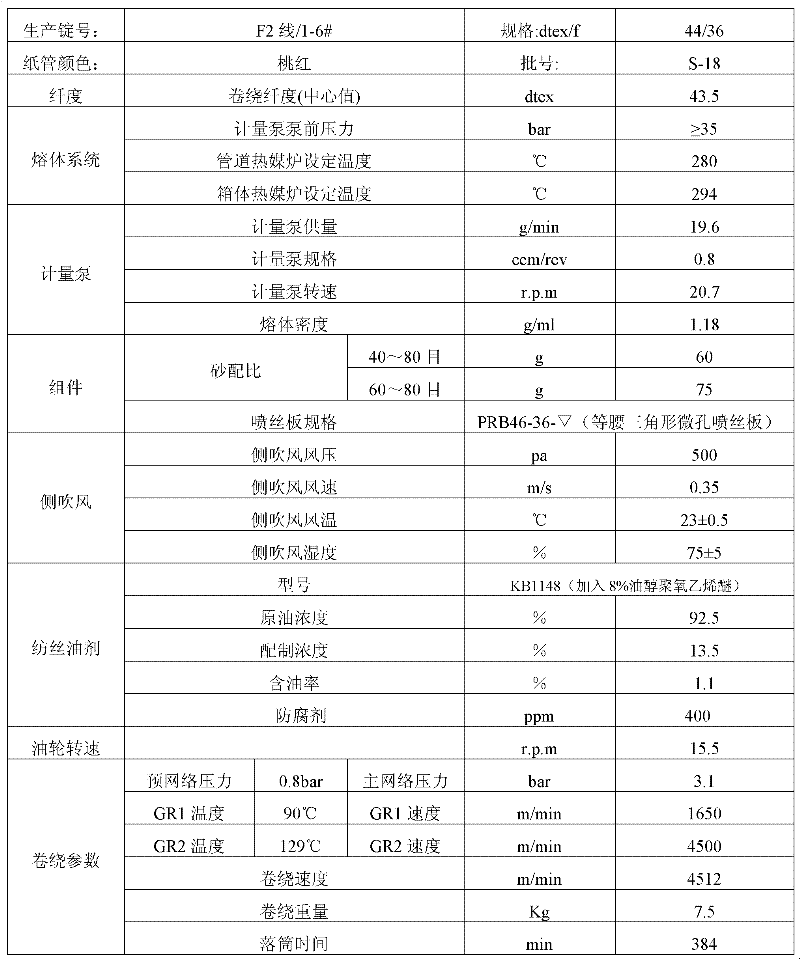

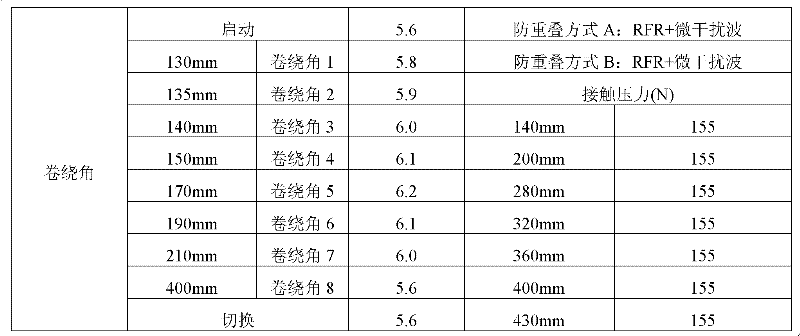

[0020] Example 1 The production specification is 44dtex / 36F glossy triangular special-shaped polyester FDY yarn

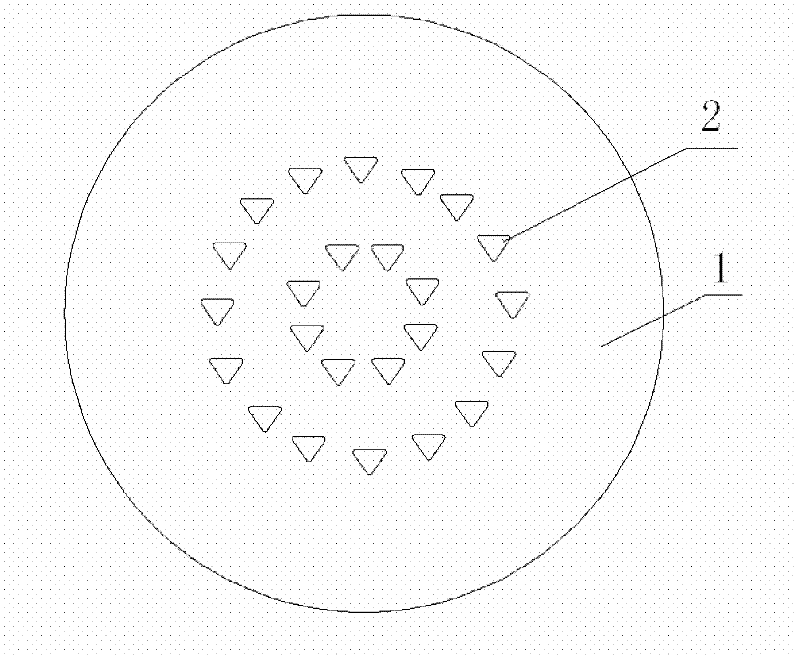

[0021] This product adopts the one-step production route of melt direct spinning. The polyester melt (PET) obtained by PTA+EG polymerization passes through the melt filter, then is boosted and transported by the gear booster pump, cooled by the cooler, and then distributed to each spinning machine. Each spinning position sends the melt quantitatively to each spinning assembly by a metering pump. After the melt is filtered and uniformly pressurized through the filter layer in the spinning assembly, it passes through the capillary-shaped spinneret (the spinneret is in the spinning In the module, isosceles triangular micropores with a vertex angle of 60-80°. The length of the bottom side of the micropore is 0.3mm) is sprayed out in a thin stream, and the melt stream is cooled by side blowing at constant temperature and humidity, and then solidified After forming silk ...

Embodiment 2

[0040] Example 2 The production specification is 47dtex / 24F glossy triangular special-shaped polyester FDY yarn

[0041]This product adopts the one-step production route of melt direct spinning. The polyester melt (PET) obtained by PTA+EG polymerization passes through the melt filter, then is boosted and transported by the gear booster pump, cooled by the cooler, and then distributed to each spinning machine. Each spinning position sends the melt quantitatively to each spinning assembly by a metering pump. After the melt is filtered and uniformly pressurized through the filter layer in the spinning assembly, it passes through the capillary-shaped spinneret (the spinneret is in the spinning In the component, isosceles triangular micropores with an included angle of 60-80°. The length of the bottom side of the micropore is 0.3mm) is sprayed out in a thin stream, and the melt stream is cooled by side blowing at constant temperature and humidity, and then solidified After forming ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com