Low-energy-consumption no-motor-drive type transmission device used for stenter

A tenter setting machine and conveying device technology, applied in the direction of fabric elongation, textile processing machine accessories, textile material processing, etc., to achieve the effects of reducing energy consumption, eliminating friction, and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

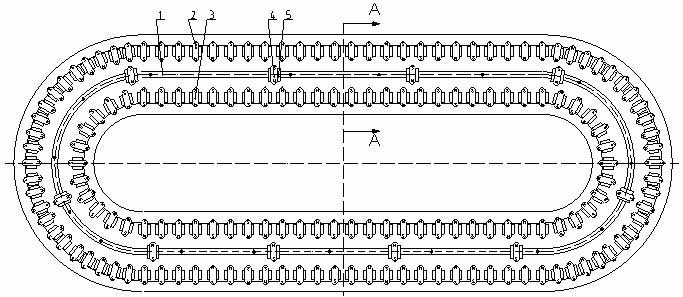

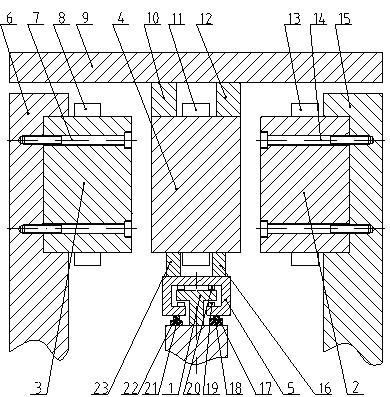

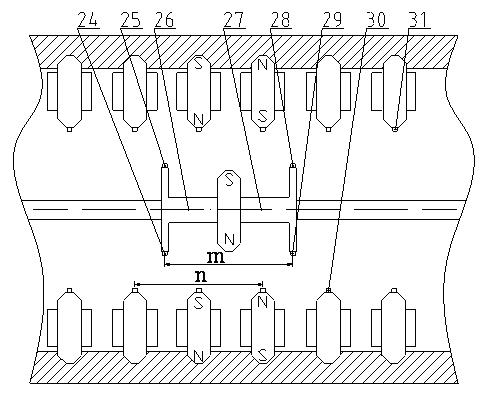

[0023] See attached figure 1 , 2 , 3, 4, 5, 6, 7, a low energy consumption non-motor-driven transmission device used in a stenter setting machine, including brackets 6, 15, and the uniform installation on the brackets 6, 15 is made of soft magnetic materials The static magnets 2 and 3 of the two brackets are equipped with a guide rail support at the central position of the two brackets. The magnetic suspension static guide rail 1 and the auxiliary support static guide rails 17 and 21 are installed on the guide rail support. The magnetic suspension dynamic guide rail 5 is set on the magnetic suspension static guide rail 1, and the magnetic suspension dynamic guide rail The inner side of 5 is equipped with bearing electromagnet 19,20, and the auxiliary support moving guide rail 18,22 is installed at the position relative to the auxiliary supporting static guide rail 17,21 at the bottom of the magnetic levitation moving guide rail 5 outside, and the lower support block 16,23 is i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com