Gear rack type inertial container with variable inertial coefficient

A technology of inertia coefficient and rack and pinion is applied in the field of inertial container devices, which can solve the problems of large self-weight and instantaneous large impedance, and achieve the effect of reducing self-weight and having a simple and easy structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

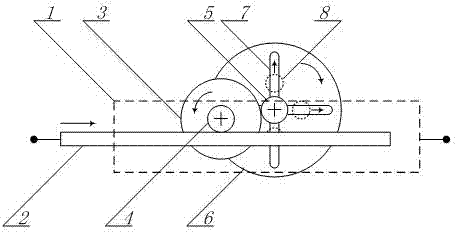

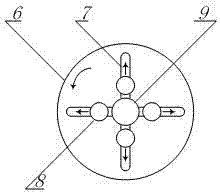

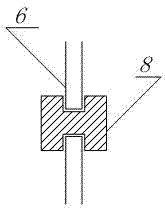

[0019] exist figure 1 Among them, the rack 2 is placed in the guide rail of the box 1 and can move in translation. The rack 2 and the box 1 are two opposite free ends of the inerter. The rack 2 meshes with the pinion shaft B4, the pinion shaft B4 and the bull gear 3 are coaxially connected and fixed on the box body 1, the pinion shaft A5 meshes with the bull gear 3, and the flywheel 6 and the pinion shaft A5 are coaxially connected It is fixed on the box body 1, and four guide grooves 7 are opened on the flywheel 6. The length of the guide groove 7 is less than the radius of the flywheel 6. The mass block 8 is placed in the guide groove 7 and is nested so that the mass block 8 can move along the The guide groove 7 slides radially.

[0020] exist figure 2 Among them, a magnetic ferrule is placed at the axis of the flywheel 6 to ensure that the mass 8 can be adsorbed near the axis of the flywheel when it is still.

[0021] Let the gear radius of the pinion shaft B4 be r 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com