Single-fiber bidirectional component and packaging method thereof

A single-fiber bidirectional, component technology, applied to the coupling of optical waveguides and other directions, can solve the problem of low yield and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

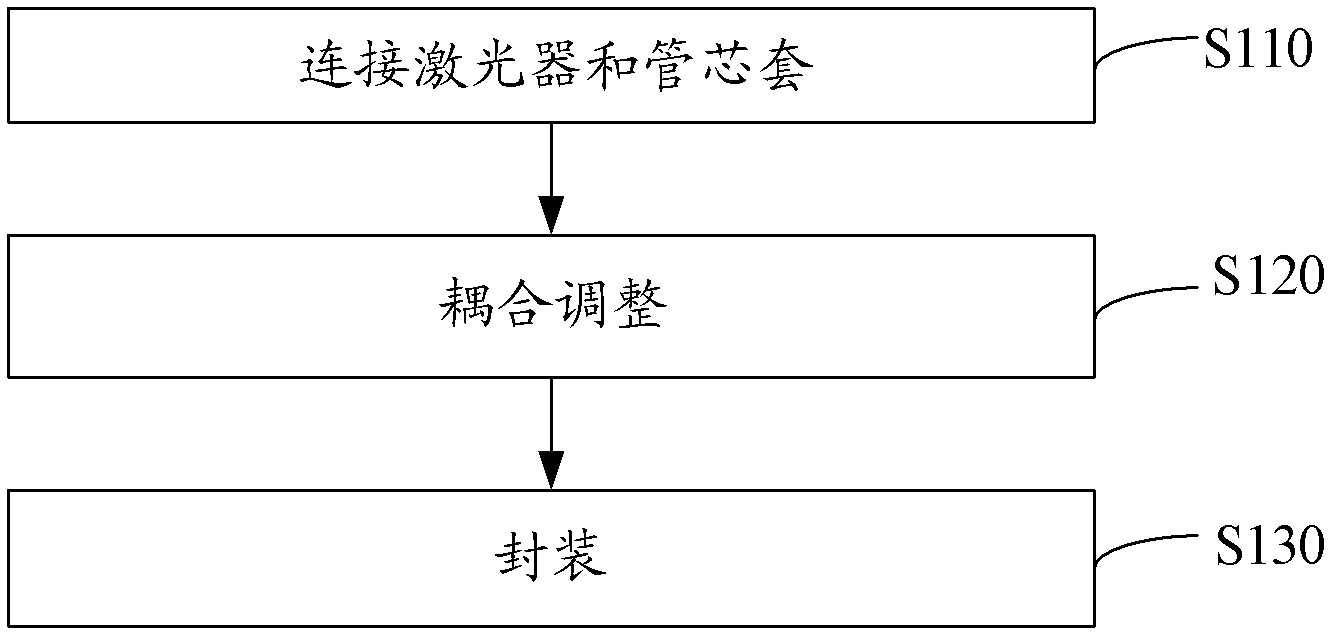

[0021] In order to solve the problem of low yield rate existing in the existing single-fiber bidirectional component packaging method, a single-fiber bidirectional component with high packaging yield and a packaging method thereof are proposed. The above-mentioned single-fiber bidirectional component and its packaging method will be further elaborated below through specific implementation methods.

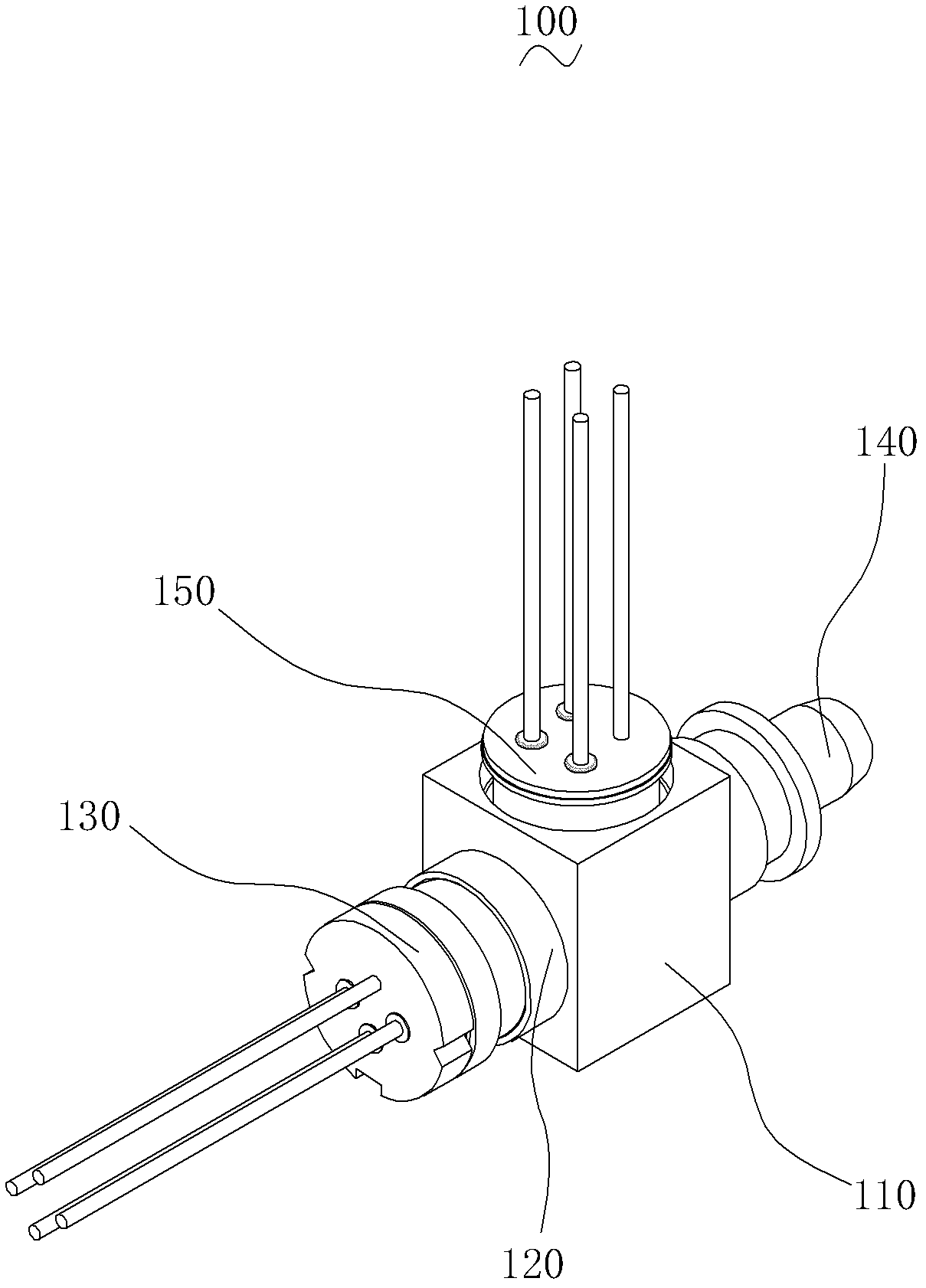

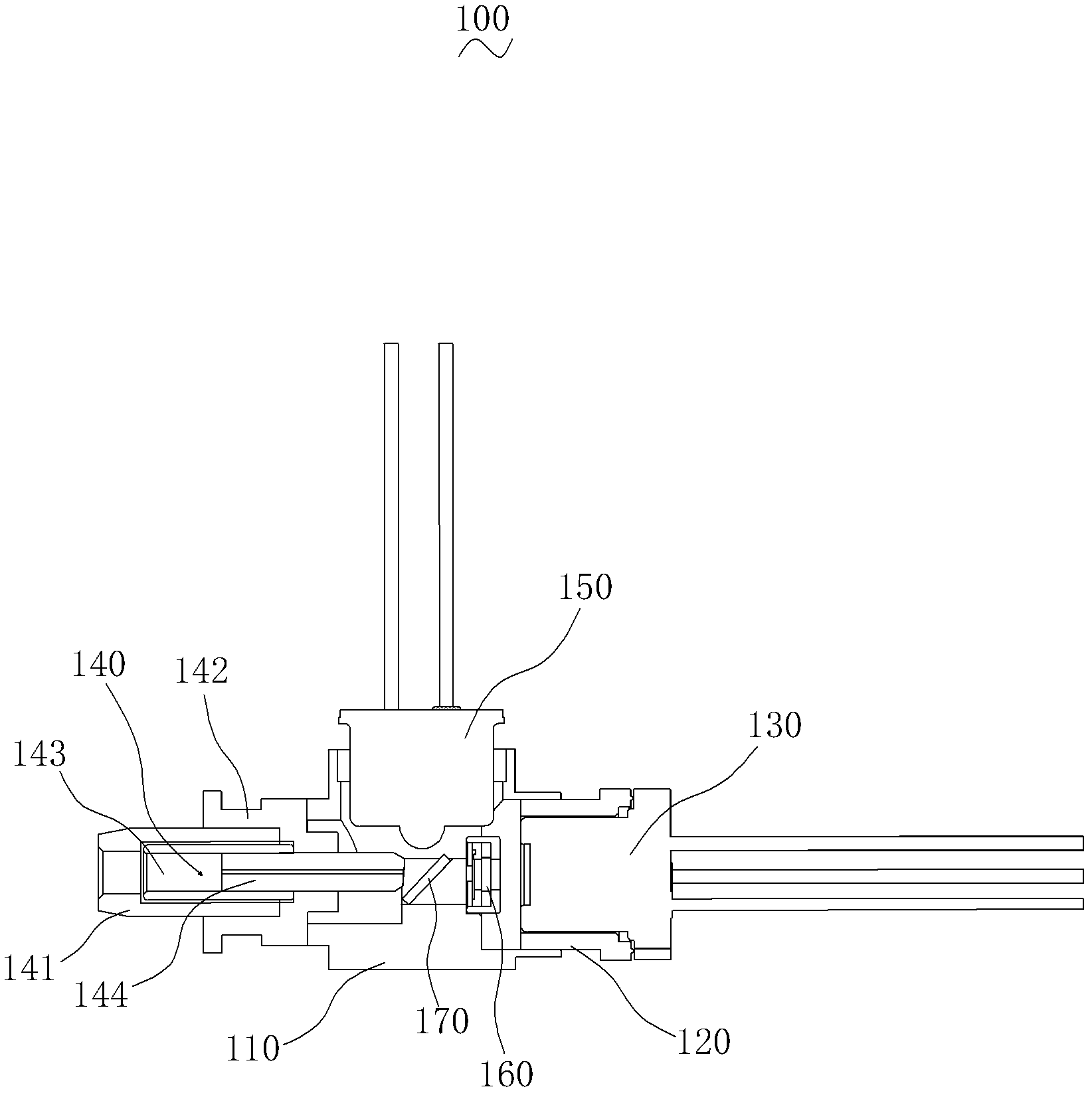

[0022] see figure 1 and figure 2 , a single-fiber bidirectional assembly 100 according to an embodiment, including a base 110 , a die sleeve 120 , a laser 130 , an adapter 140 , a receiver 150 , an isolator 160 and an optical filter 170 .

[0023] The die sleeve 120 is fixed on the base 110 . One end of the laser 130 is inserted into the die sleeve 120 . The adapter 140 and the receiver 150 are respectively arranged on the base 110 , and the receiver 150 is arranged perpendicular to the optical axis of the laser 130 , and the adapter 140 is arranged on the side of the base 110 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com