Straight rubber hose with hot melt adhesive sheath and preparation method for straight rubber hose

A technology of rubber hose and hot melt adhesive, applied in the direction of electrical components, etc., can solve problems such as sheath loosening, displacement, and sheath protection failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

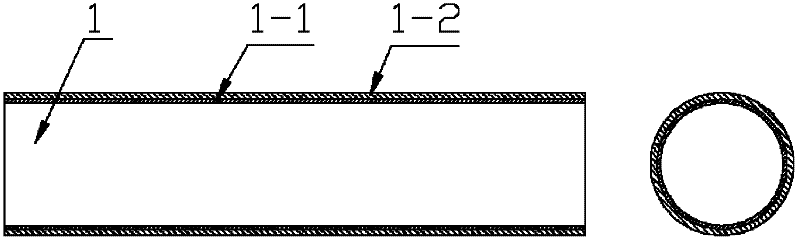

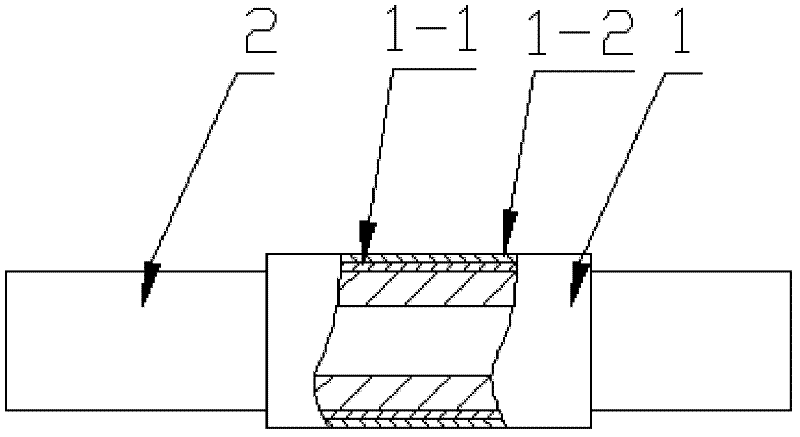

[0013] Such as figure 2 Shown: a straight rubber hose assembly with a hot-melt adhesive sheath, the hot-melt adhesive sheath 1 is fastened on the surface of the rubber tube 2, so that the rubber tube 2 has good wear resistance, and the sheath Not prone to loosening or shifting

[0014] 1. Choose a straight rubber tube with an outer diameter of 8mm 2, and the length to be protected on the tube body is 50mm;

[0015] 2. Select the hot-melt adhesive sheath 1 with an inner diameter of 10mm and a length of 50mm produced by Shanghai Changyuan Electronic Materials Co., Ltd., and put it on the position where the rubber tube 2 needs to be protected;

[0016] 3. Raise the temperature of the high-temperature heating equipment to 140°C, and put the rubber tube 2 covered with the hot-melt adhesive sheath 1 into the equipment for heat-shrinking processing;

[0017] 4. Under high temperature conditions, the molecular structure of the outer radiation cross-linked polyolefin heat shrinkable...

Embodiment 2

[0020] Such as figure 2 Shown: a rubber hose assembly with a hot-melt adhesive sheath, the hot-melt adhesive sheath 1 is fastened on the surface of the rubber tube 2, so that the rubber tube 2 has good wear resistance, and the sheath is not easy to appear loosening or displacement

[0021] 1. Select a straight rubber tube with an outer diameter of 15mm 2, and the length to be protected on the tube body is 100mm;

[0022] 2. Select the hot melt adhesive sheath 1 with an inner diameter of 25mm and a length of 100mm produced by Shanghai Changyuan Electronic Materials Co., Ltd., and put it on the position where the rubber tube 2 needs to be protected;

[0023] 3. Raise the temperature of the high-temperature heating equipment to 160°C, and put the rubber tube 2 covered with the hot-melt adhesive sheath 1 into the equipment for heat-shrinking processing;

[0024] 4. Under high temperature conditions, the molecular structure of the outer radiation cross-linked polyolefin heat shr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com