Frame for supporting a filter membrane

A filter and frame technology, which is applied in the field of frame system to manufacture the filter element, can solve the problems of damage, blockage, and insufficient purification flow strength, etc., and achieve high permeation flux, fast filtration process, and improved life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

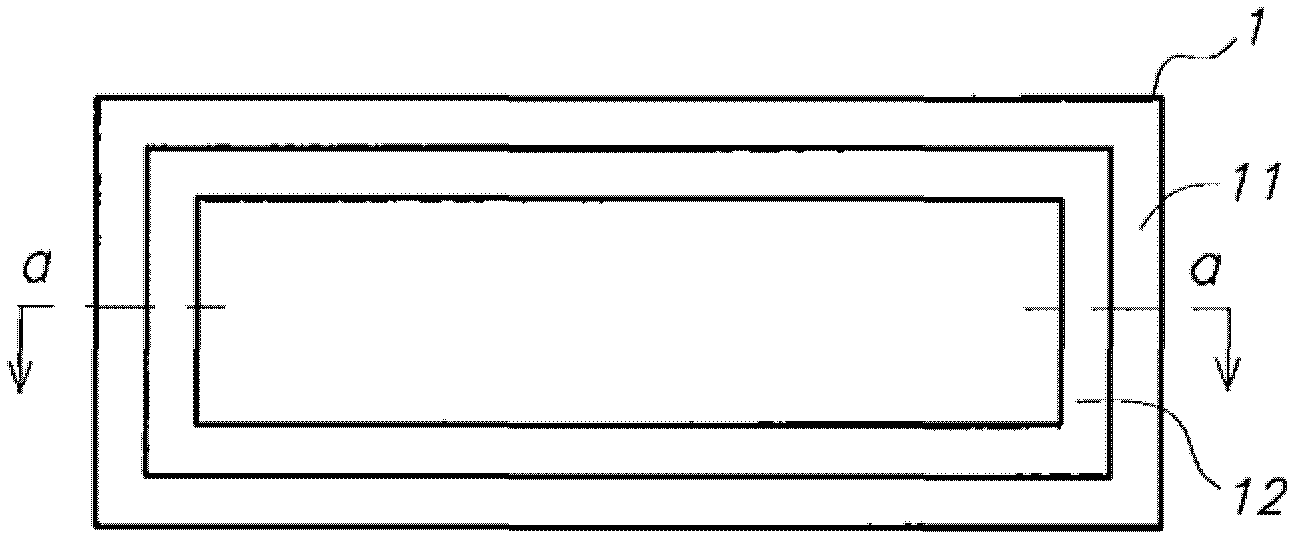

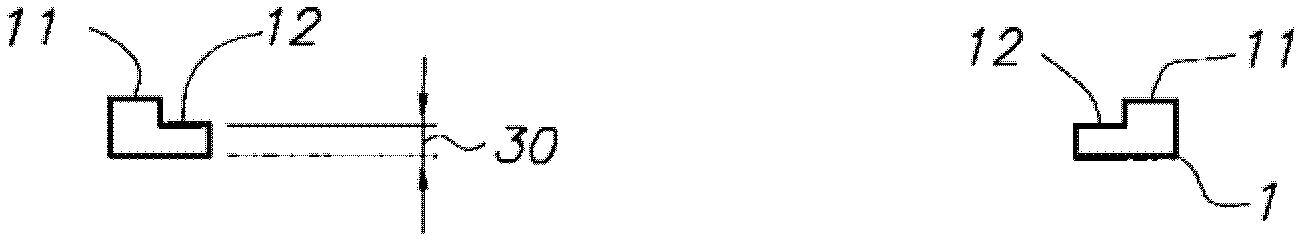

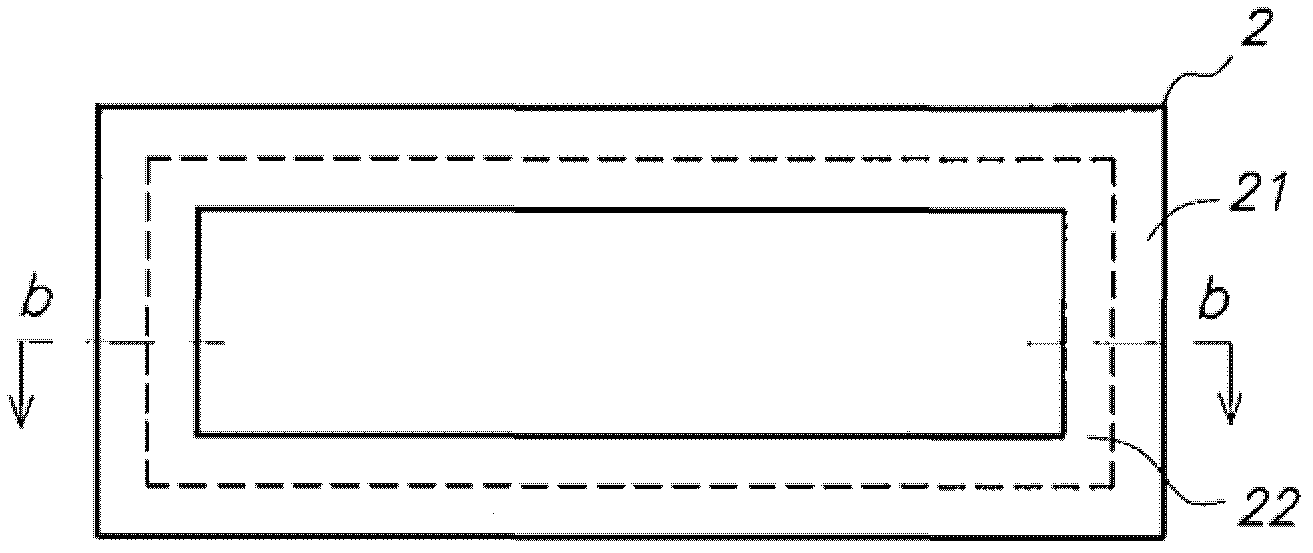

[0045] The present invention provides a filter element comprising: (i) a one-piece permeate channel membrane (4) having a flexible structure and comprising an upper membrane layer and a lower membrane layer and a support for supporting the membrane layers A base material, wherein the base is a 3D spacer fabric having an upper fabric surface and a lower fabric surface joined together by monofilament threads and spaced apart by a predetermined distance, wherein the upper and lower fabric surfaces each of which is provided with at least one membrane layer forming said upper and lower membrane layers, and wherein a permeate channel is interposed between said upper and lower membrane layers and is connected to an output opening for discharging said integral permeate channel and (ii) a frame system that supports the membrane and seals the one-piece permeate channels at the edges of the membrane, the frame system comprising a first frame profile (1 or 5) and a second frame profile ( ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com