Large-power mulberry shoot reaper

A cutting machine and high-power technology, applied in the field of mulberry cutting machines, can solve the problems of high stubble injury rate, no high-powered cutting machine, and inability to operate for a long time, reducing labor intensity, smoothing the incision, and facilitating recovery. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

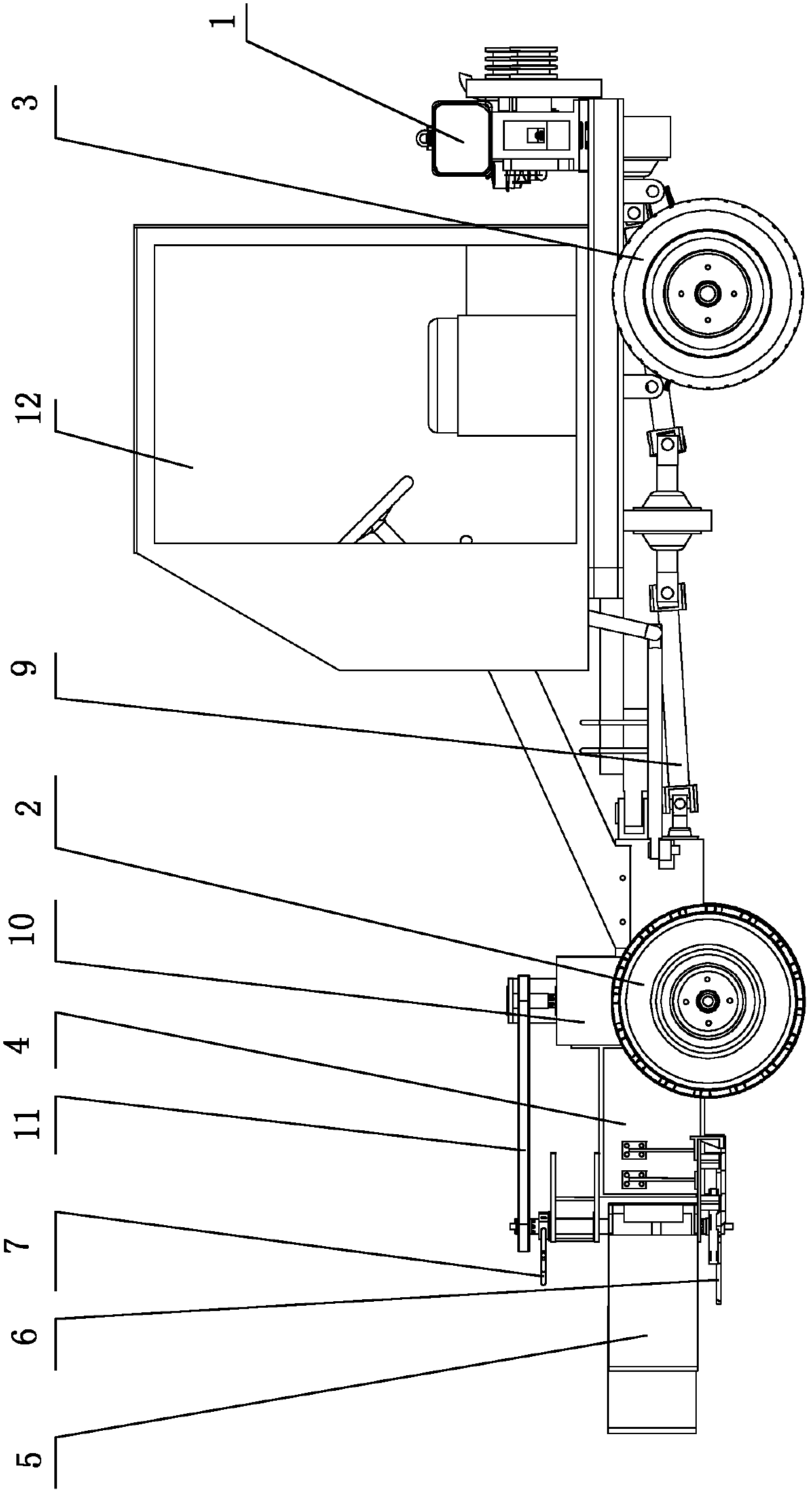

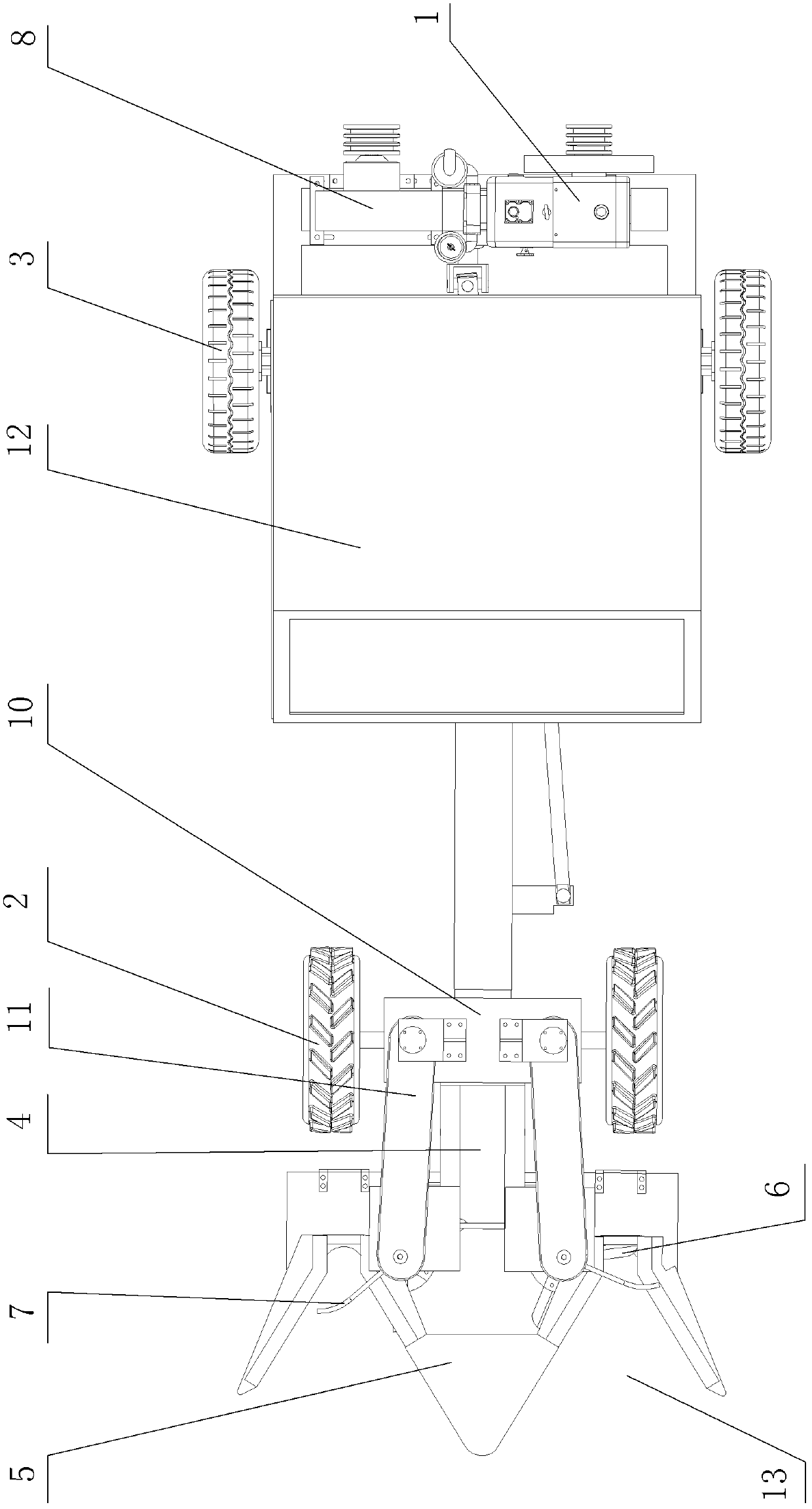

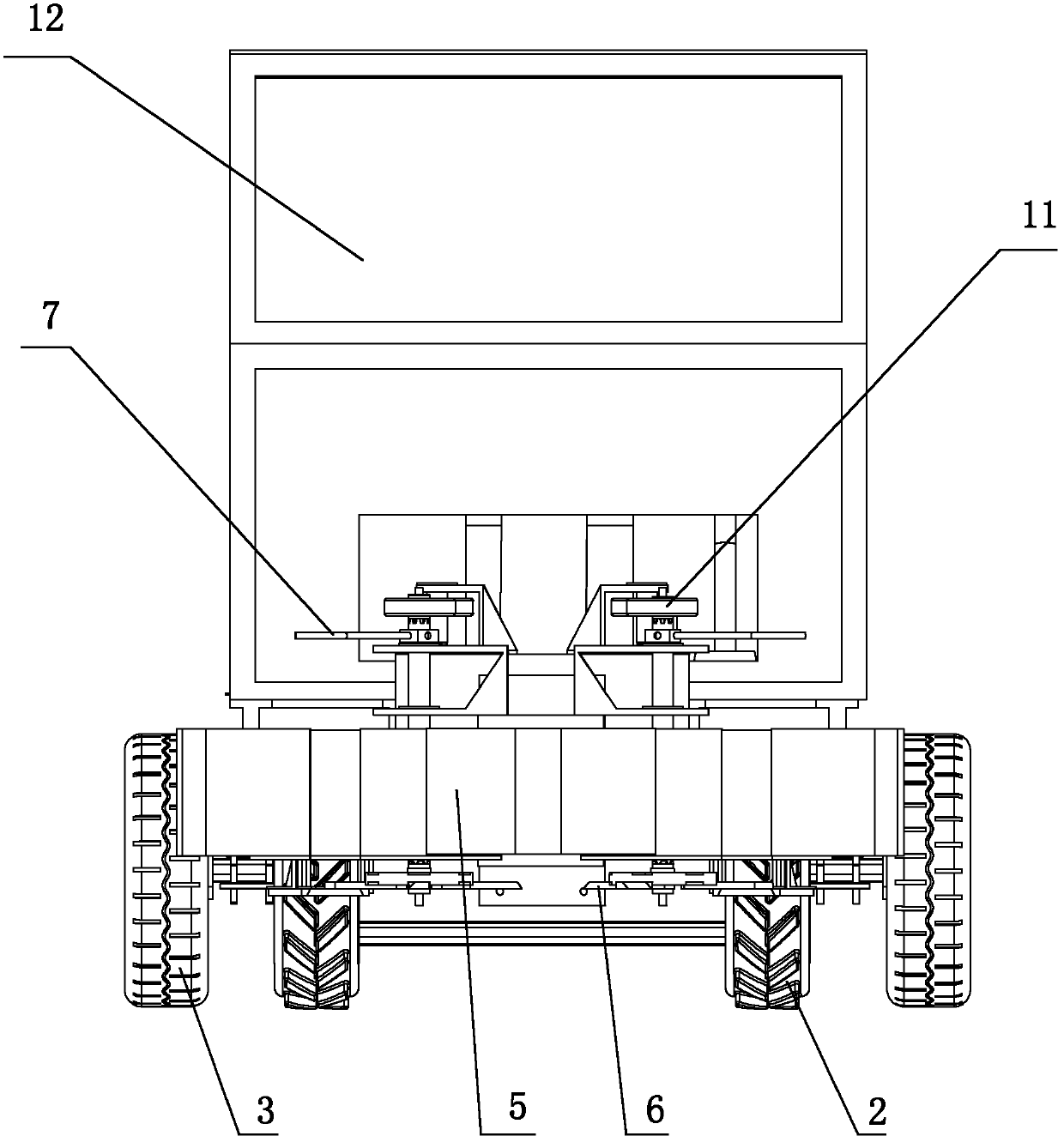

[0021] Now in conjunction with accompanying drawing technical scheme of the present invention is described further:

[0022] The large-power mulberry cutting machine of the present invention comprises a traveling mechanism, a power mechanism and a shearing mechanism.

[0023] The traveling mechanism adopts a common four-wheel tractor structure with two front wheels 2 and two rear wheels 3, and the power mechanism adopts a diesel engine 1 as a power source, and the diesel engine 1 is arranged behind the driver's cab 12, and transmits power through the main transmission device. The main transmission device includes a reduction box 8, a delivery shaft 9 and a gearbox 10. After the power of the diesel engine 1 is decelerated by the reduction box 8, it is output to the gearbox 10 on the headstock 4 through the delivery shaft 9, and the left and right sides of the gearbox 10 output The shaft distributes a part of the power to the two front wheels 2 to realize the walking of the four...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com