Noodle maker

A noodle rolling machine and frame technology, applied in the field of noodle rolling machines, can solve the problems of difficulty in satisfying commercial hand-rolled noodles, poor noodle taste, high labor intensity, etc., achieve convenient and quick maintenance and replacement of blades, novel structure, and reduce The effect of labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

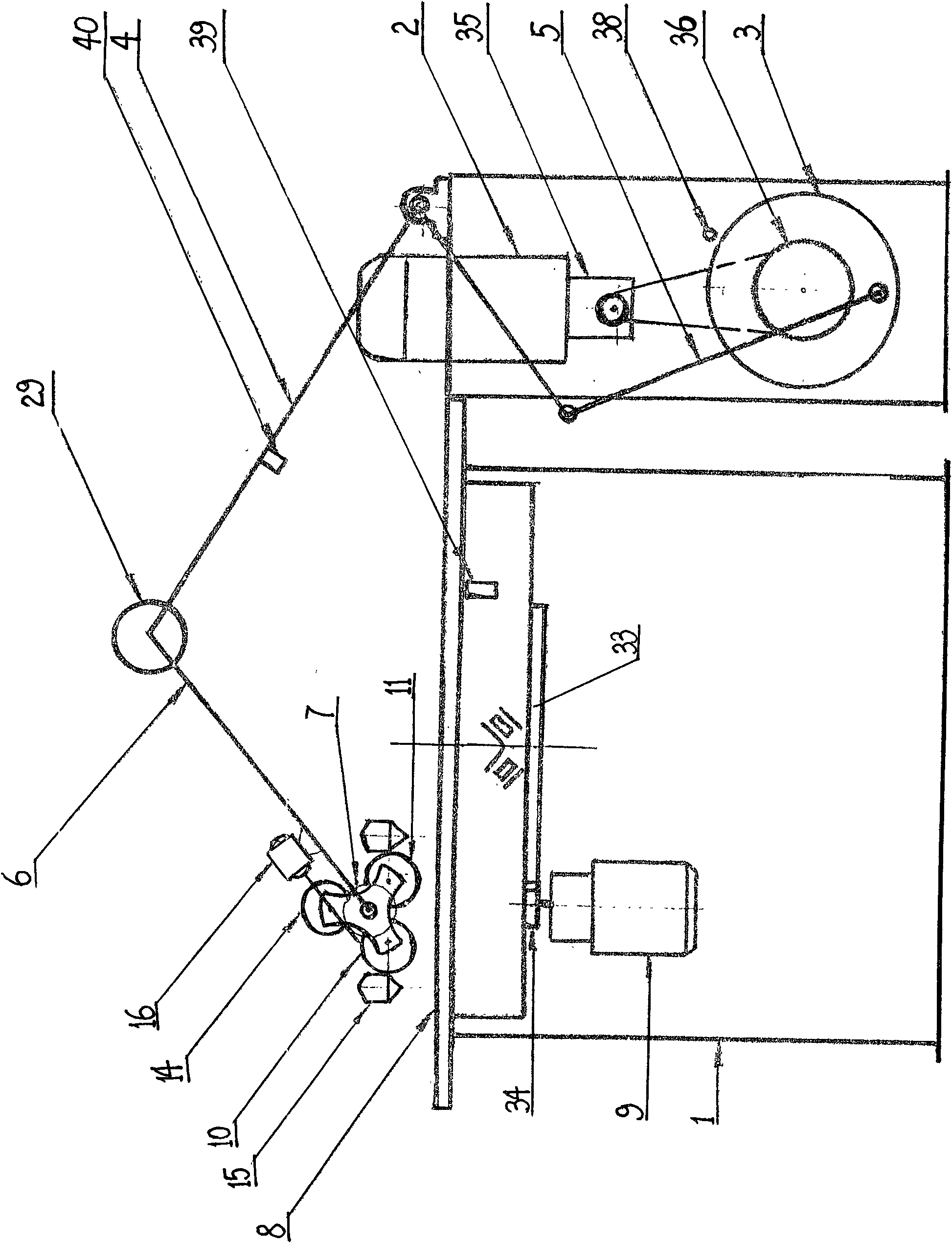

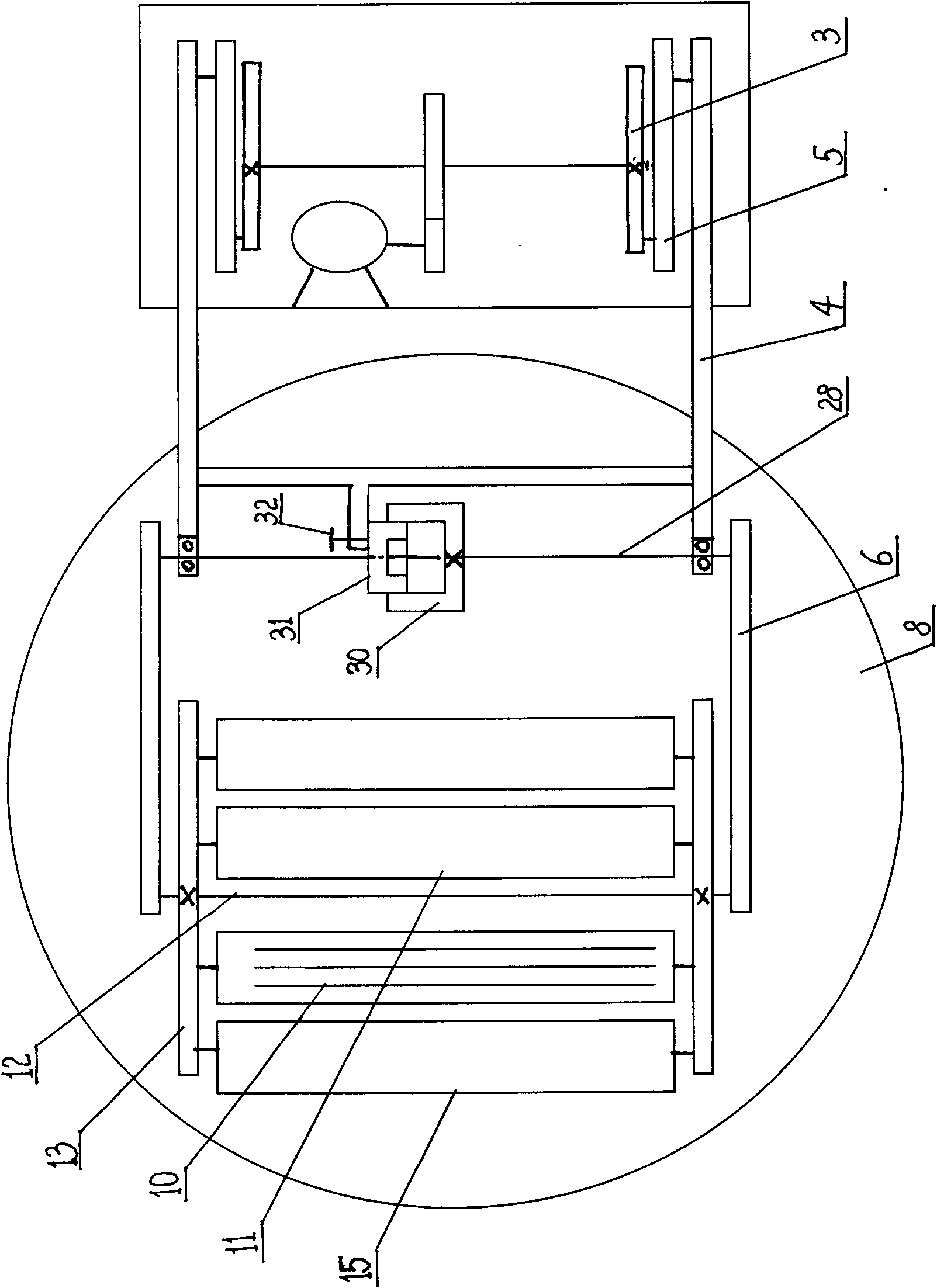

[0025] Attached below figure 1 , 2 , 3, 4, 5, 6 describe the first embodiment of the present invention.

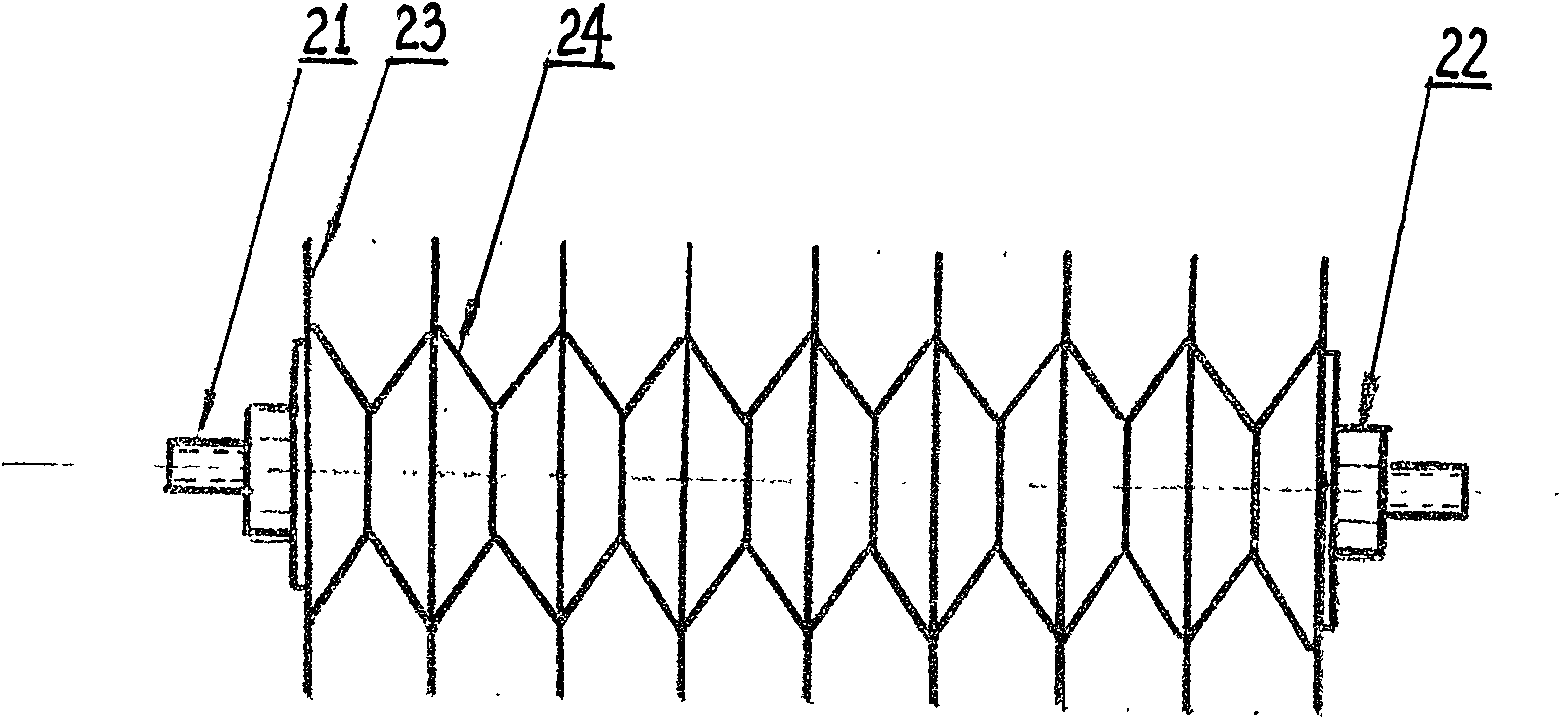

[0026] A kind of noodle rolling machine, comprising a frame 1, a motor I2, two coaxial eccentric wheels 3 are installed on one side of the frame 1, and a large swing arm 4 is hinged, and the eccentric wheel 3 is located under the motor I2 The eccentric wheel 3 is connected with a link mechanism 5, and the upper ends of the two link mechanisms 5 are coaxially fixedly connected with the lower end of the large swing arm 4 respectively, and the upper end of the small swing arm 6 is hinged on the upper end of the large swing arm 4 , the lower end of the small swing arm 6 is horizontally equipped with a rolling cylinder assembly 7; Above, the lower end surface of the circular horizontal workbench 8 is fixed with a large gear 33, and the main shaft of the reduction motor II9 is fixed with a pinion 34, and the reduction motor II9 drives the horizontal workbench 8 to rotate thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com