Apparatus for making a fibrous article having a three dimensional profile

A fiber product, three-dimensional contour technology, applied in applications, apparel, underwear, etc., can solve problems such as increasing manufacturing complexity, affecting product liquid handling characteristics, and increasing final product cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0118] Specific inventive examples and comparative examples of the present invention are described below.

[0119] Invention Example #1

[0120] An example of a sanitary napkin according to the present invention is constructed as follows. The body-facing cover was prepared with a hot-air (HTA) bonded nonwoven material having a basis weight of 27 gsm and consisting of 100% conjugated fibers (PE / PET) available from Shalag Industries A.C.S.Ltd. ( Kibbutz Shamir, Upper Galilee, Israel) was commercially available.

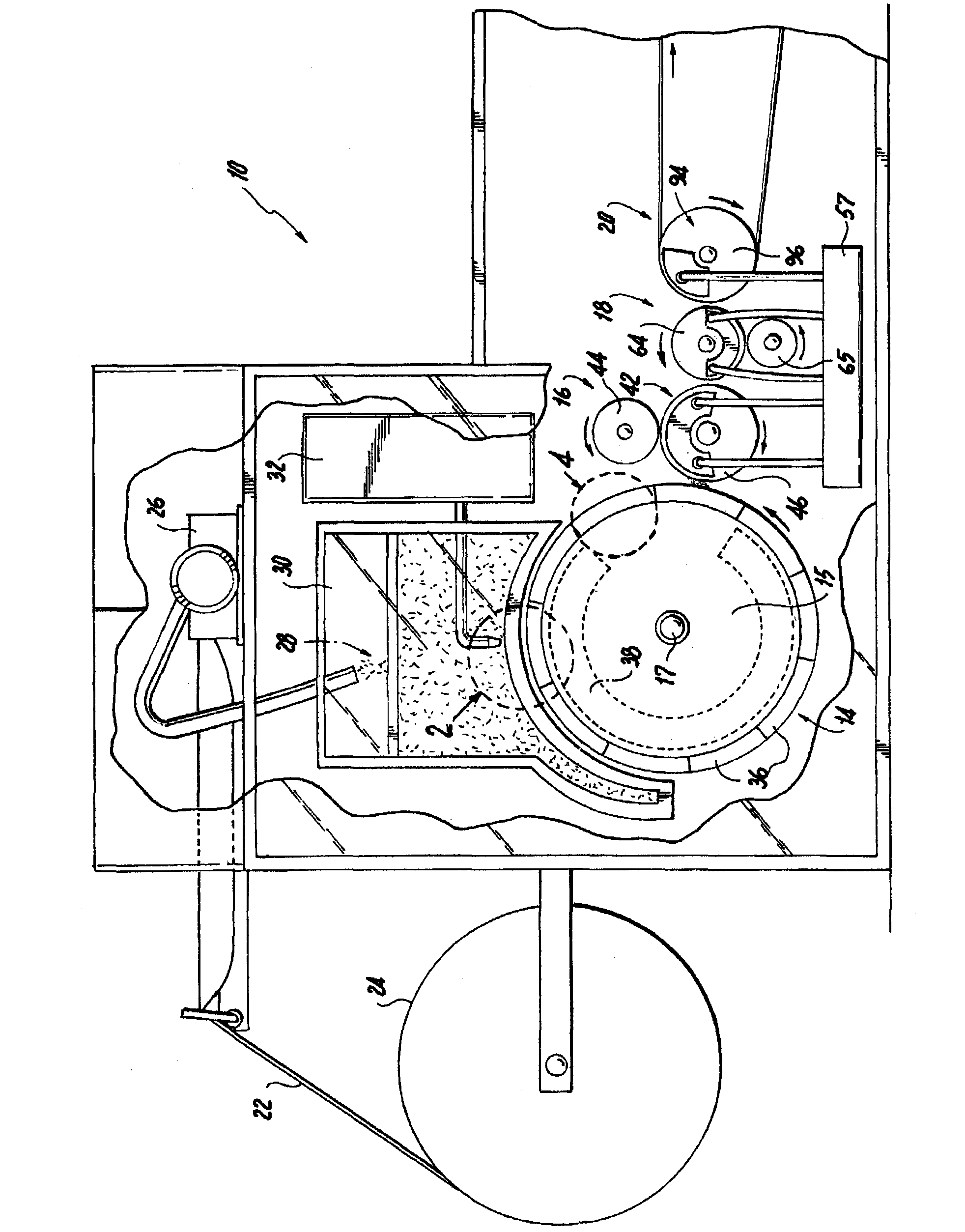

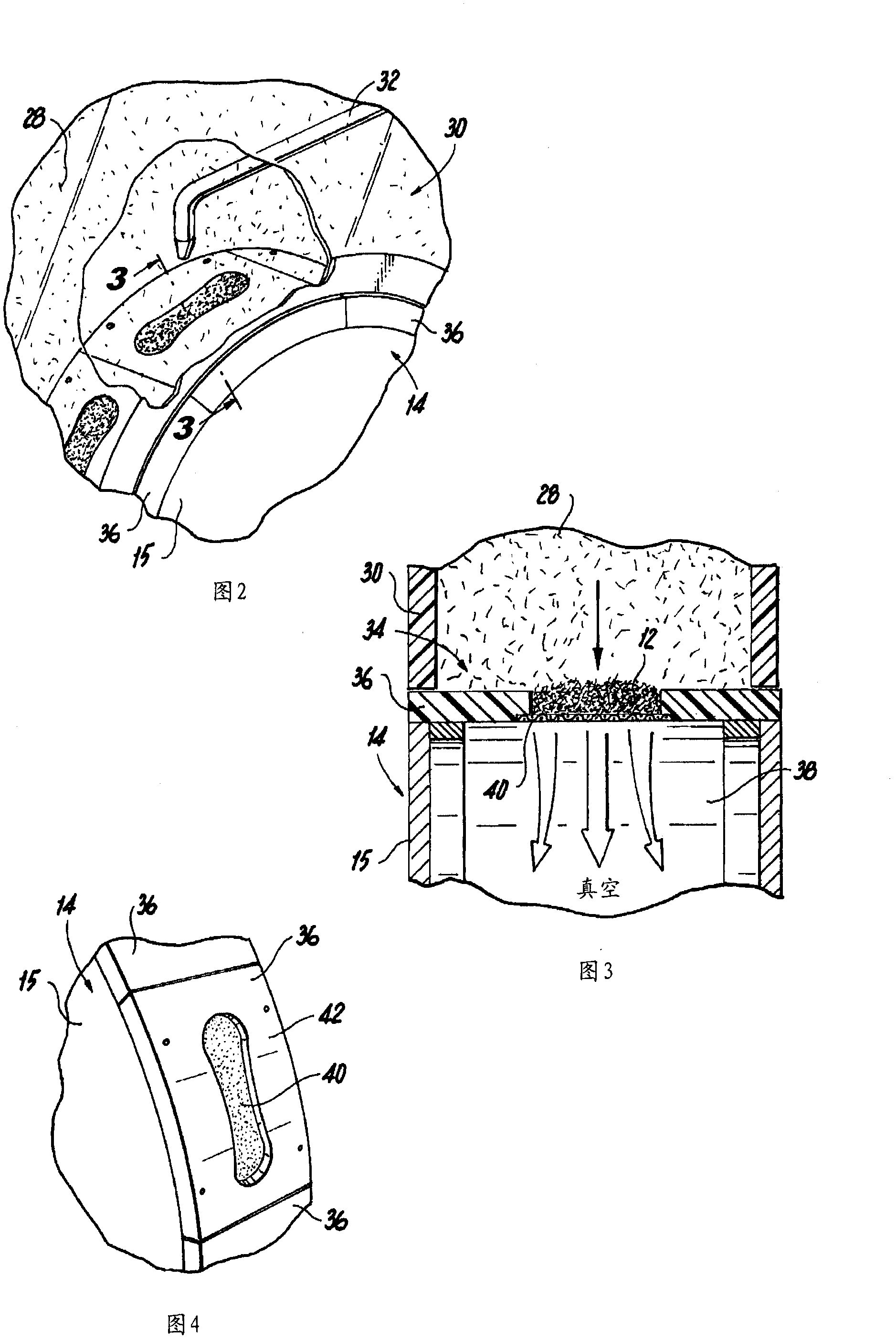

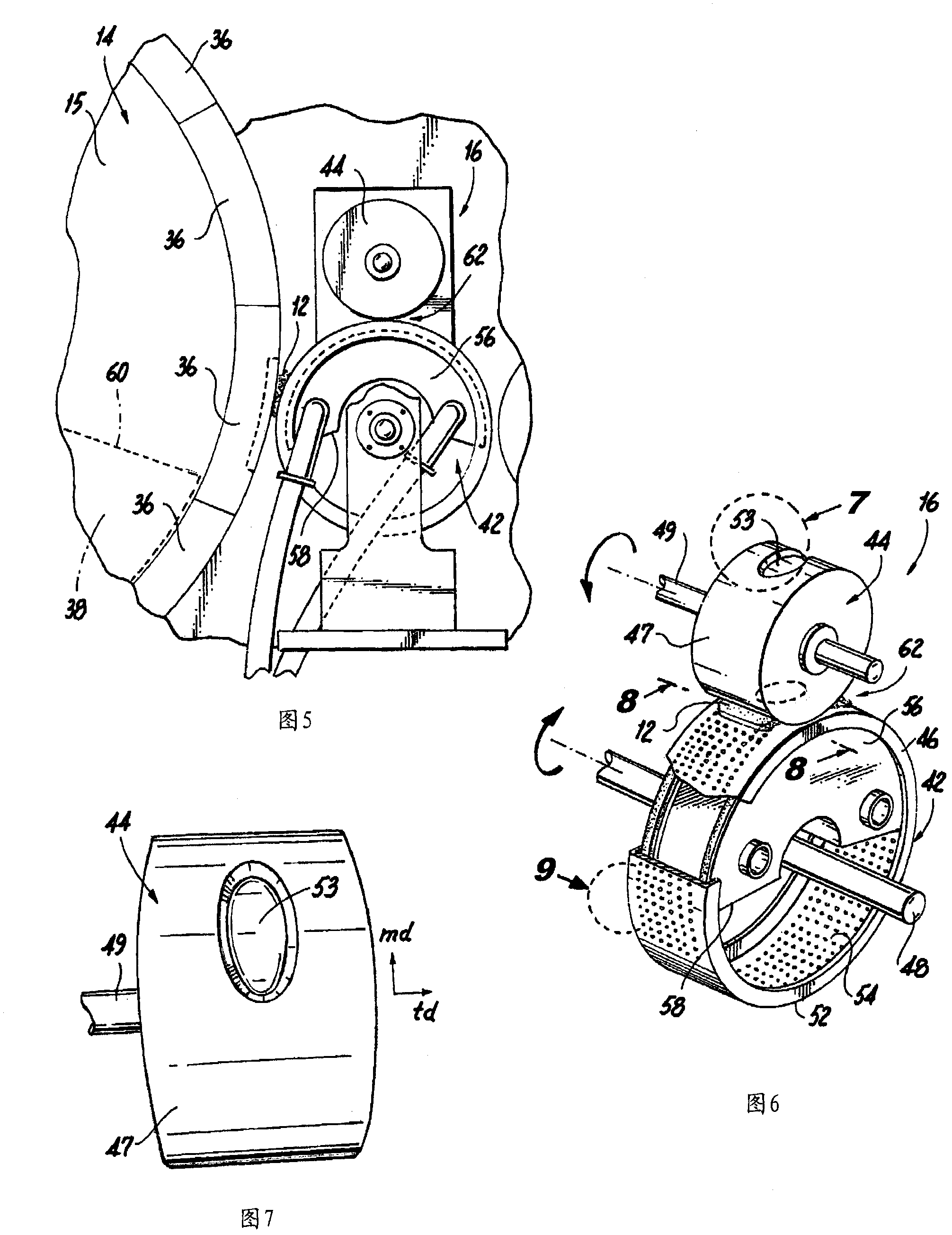

[0121] A 305 gsm shaped fiber absorbent core is placed under the cover layer, the shaped fiber absorbent core combined as above Figure 1-21 The method is formed.

[0122] The absorbent core consisted of 89% by weight pulp and 11% by weight superabsorbent polymer. The pulp was Golden Isles fluff pulp 420 #HD (moisture 7%) commercially available from GP Cellulose (Brunswick, Georgia, USA). The superabsorbent polymer was Aqua Keep SA70N commercially available from ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com