Multi-tube pass inorganic separating membrane module

A separation membrane, multi-tube technology, applied in semi-permeable membrane separation, membrane technology, chemical instruments and methods, etc., can solve the problems of uneven material distribution, reduced membrane separation efficiency, increased energy consumption, etc., to achieve mechanical strength adaptation. Good performance, stable heat transfer, uniform heat transfer and excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

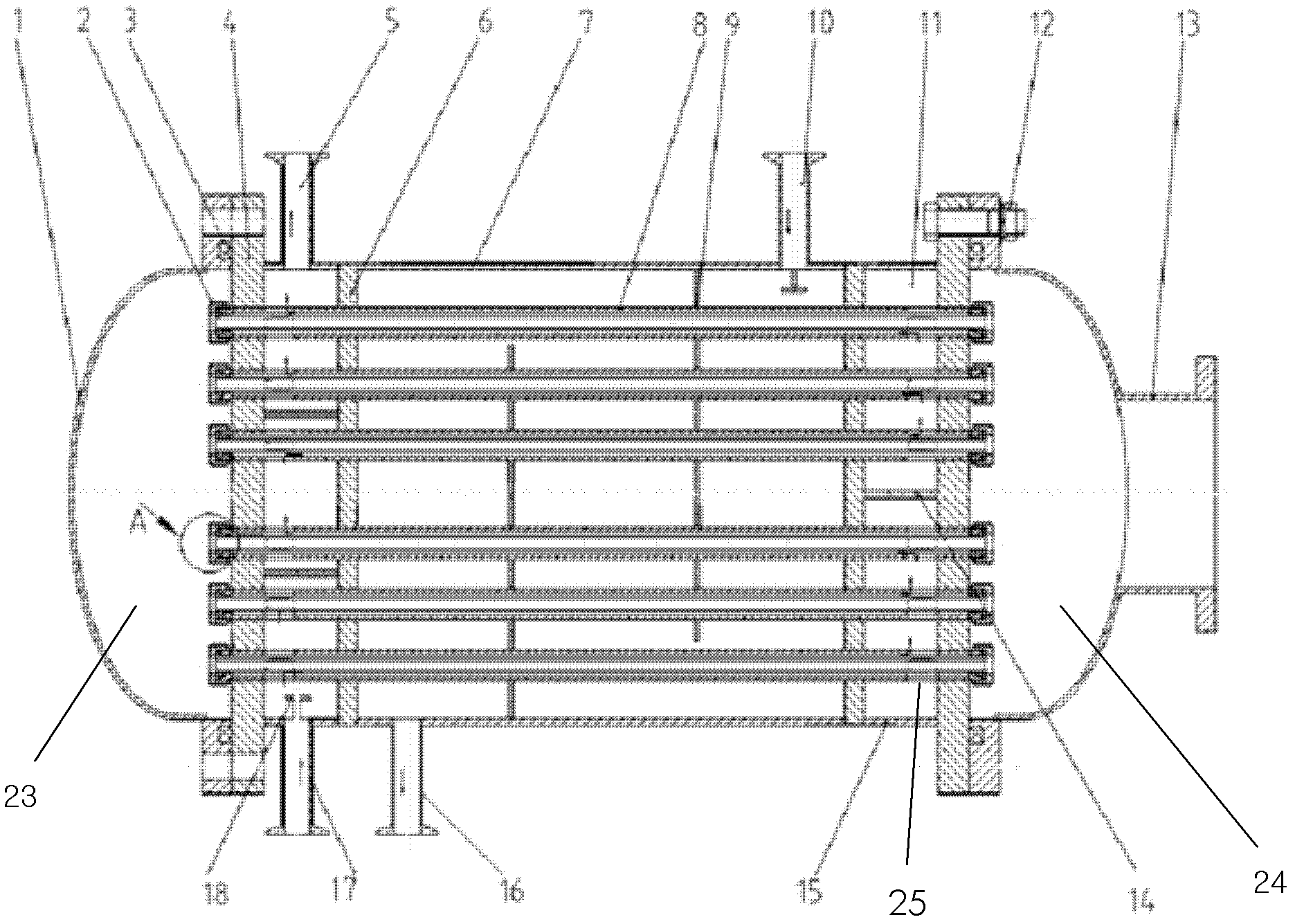

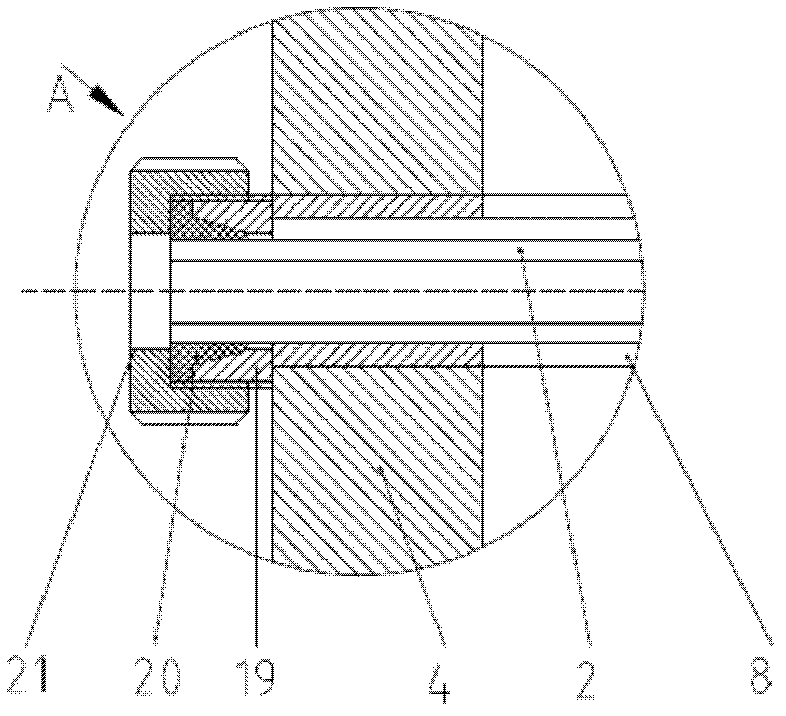

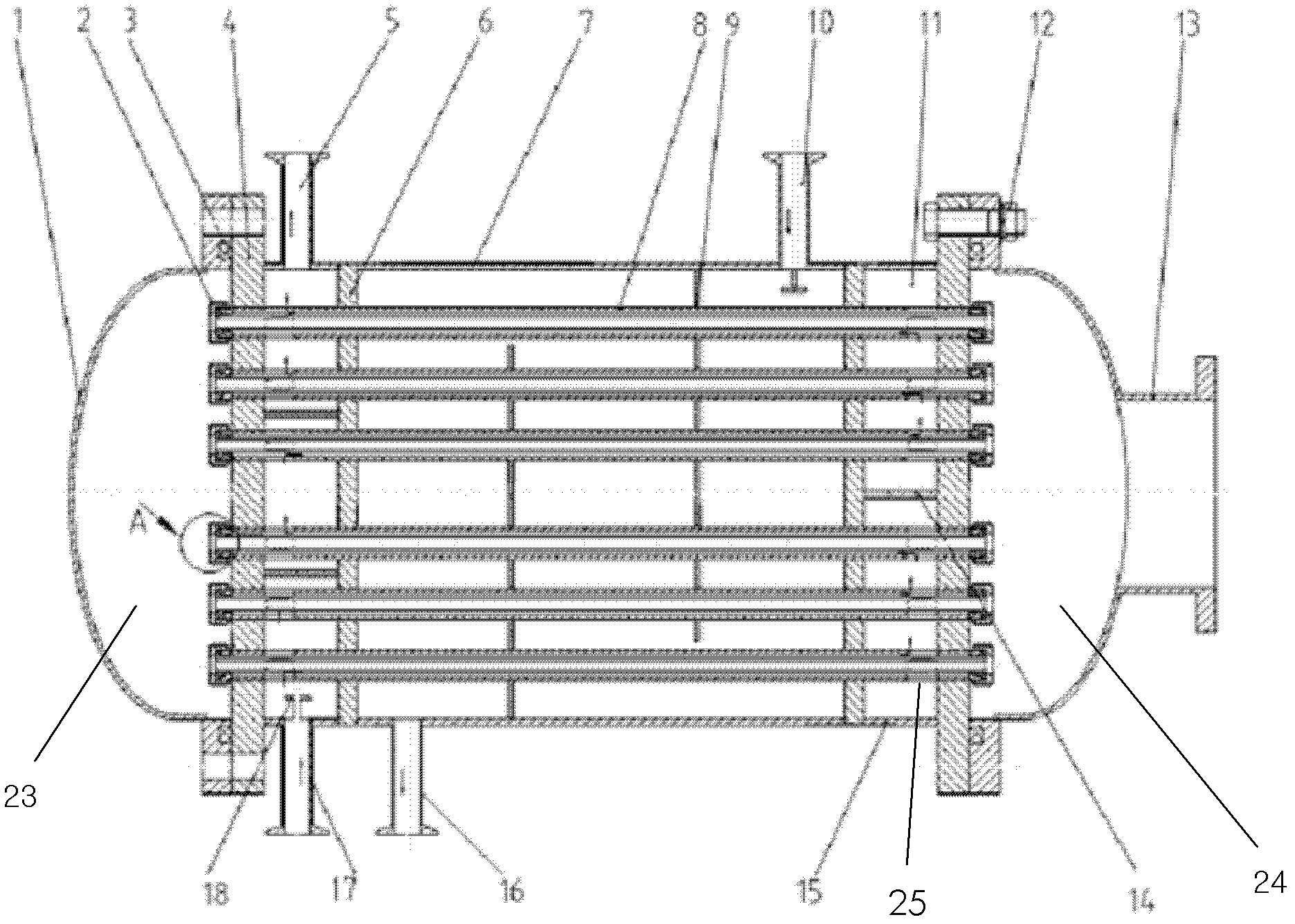

[0016] like figure 1 As shown in the figure, a multi-tube inorganic separation membrane module is composed of a tubular membrane tube 2, a faceplate plate 6, a tube plate 4, an outer casing 7 and a cover 1. The outer casing 7 is a horizontal hollow cylindrical body, and the left and right sides of the outer casing 7 are The two ends are respectively provided with tube sheets 4 , and the edges of the tube sheets 4 seal the two outlets of the casing 7 . On the inner side of the tube sheets at both ends, at a short distance, there are respectively face plates 6 that are parallel to the tube sheets. The outer edge of the face plate 6 is connected with the shell 7 as a whole. The tube sheet 4 and the face plate 7 are respectively provided with a number of corresponding One or more tubular membrane tubes 2 pass through the holes on the two faceplate plates 6 and the tube plates 4, and rest on the two faceplate plates 6 and the tube plates 4. The ends protrude out of the two tube sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com