Emulsion spraying method and emulsion spraying system for producing steel types with yield strength higher than 400MPa

A yield strength, 400mpa technology, applied in the field of pickling and rolling, can solve problems such as affecting production stability and product quality, high production costs, rolling mill vibration, etc., to improve production efficiency and yield level, and eliminate the phenomenon of rack vibration. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

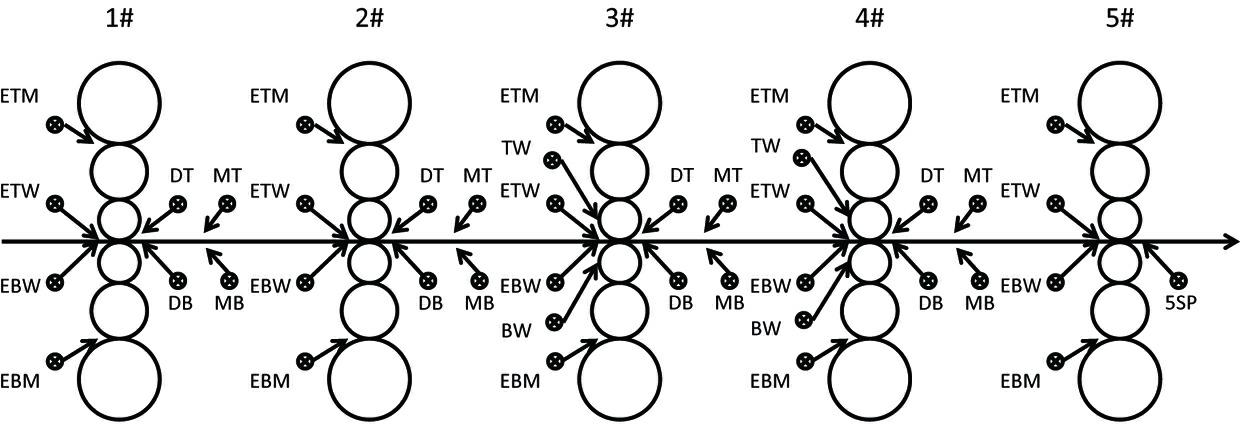

[0035] The spray beams ETW and EBW of each frame spray the emulsion on the entrance side roll gap area of the upper and lower work rolls respectively. The distance between each nozzle on the spray beam is 30mm, and the emulsion is sprayed at a low pressure of 0.45MPa.

[0036] The spray beams ETM and EBM of each frame spray the emulsion on the roll gap area of the upper and lower back-up rolls respectively. The distance between each nozzle on the spray beam is 30mm, and the emulsion is sprayed at a high pressure of 0.8MPa.

[0037] The spray beams DT and DB of each frame spray the emulsion on the exit side roll gap area of the upper and lower work rolls respectively. The distance between each nozzle on the spray beam is 30mm, and the emulsion is sprayed at a high pressure of 0.8MPa.

[0038] On the entrance side of #3 and 4# of the 3rd and 4th racks, spray beams TW and BW on the surface of the work rolls are additionally arranged. The distance between each nozzle on the s...

Embodiment 2

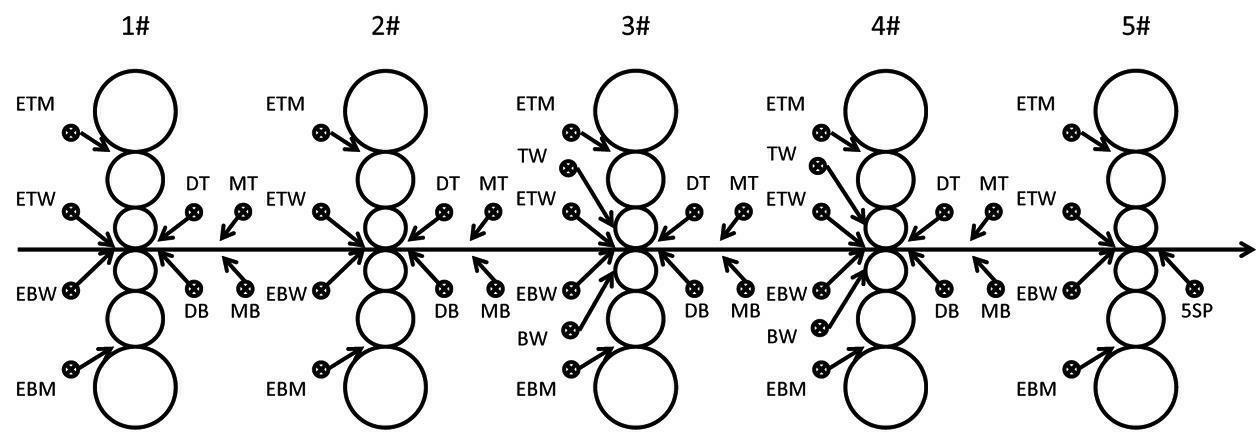

[0041] The spray beams ETW and EBW of each frame spray the emulsion on the entrance side roll gap area of the upper and lower work rolls respectively. The distance between each nozzle on the spray beam is 40mm, and the emulsion is sprayed at a low pressure of 0.5MPa.

[0042] The spray beams ETM and EBM of each frame spray the emulsion on the roll gap area of the upper and lower back-up rolls respectively. The distance between each nozzle on the spray beam is 40mm, and the emulsion is sprayed at a high pressure of 0.85MPa.

[0043] The spray beams DT and DB of each frame spray the emulsion on the exit side roll gap area of the upper and lower work rolls respectively. The distance between each nozzle on the spray beam is 40mm, and the emulsion is sprayed at a high pressure of 0.85MPa.

[0044]On the entrance side of 3# and 4# of the 3rd and 4th racks, spray beams TW and BW on the work roll surface are also arranged. The distance between each nozzle on the spray beam is 40m...

Embodiment 3

[0047] The spray beams ETW and EBW of each frame spray the emulsion on the entrance side roll gap area of the upper and lower work rolls respectively. The distance between each nozzle on the spray beam is 45mm, and the emulsion is sprayed at a low pressure of 0.55MPa.

[0048] The spray beams ETM and EBM of each frame spray the emulsion on the roll gap area of the upper and lower back-up rolls respectively. The distance between each nozzle on the spray beam is 45mm, and the emulsion is sprayed at a high pressure of 0.9MPa.

[0049] The spray beams DT and DB of each frame spray the emulsion on the exit side roll gap area of the upper and lower work rolls respectively. The distance between each nozzle on the spray beam is 45mm, and the emulsion is sprayed at a high pressure of 0.9MPa.

[0050] On the entrance side of 3# and 4# of the 3rd and 4th racks, spray beams TW and BW on the surface of the work rolls are also arranged. The distance between each nozzle on the spray bea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com