Stereoscopic combined material rack

A material rack, three-dimensional technology, applied in the field of material racks, can solve the problems of wasting storage space and floor space, unusable forming and stamping materials, and material surface crushing, etc., to reduce labor intensity, fast processing cycle, and safety performance. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

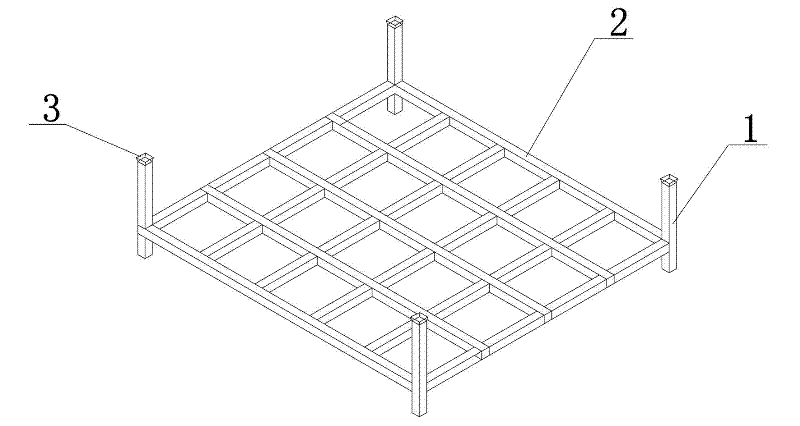

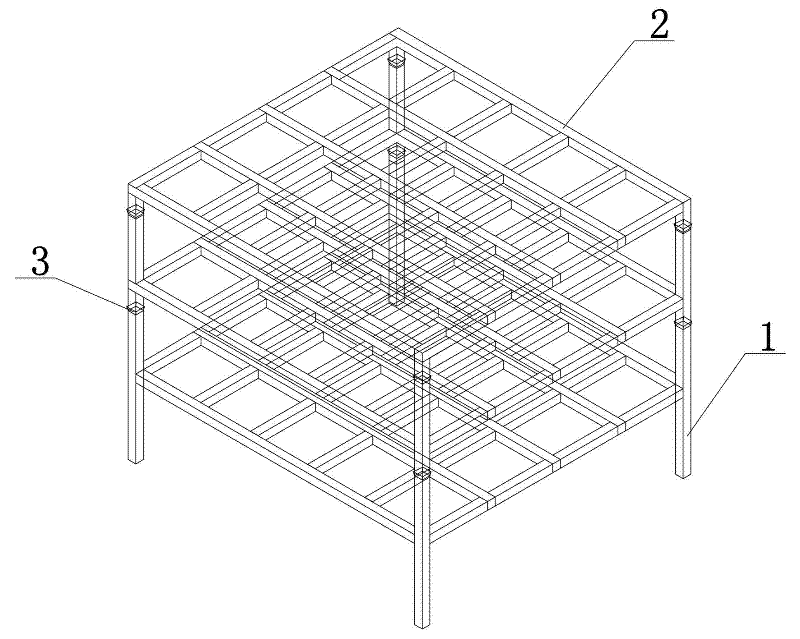

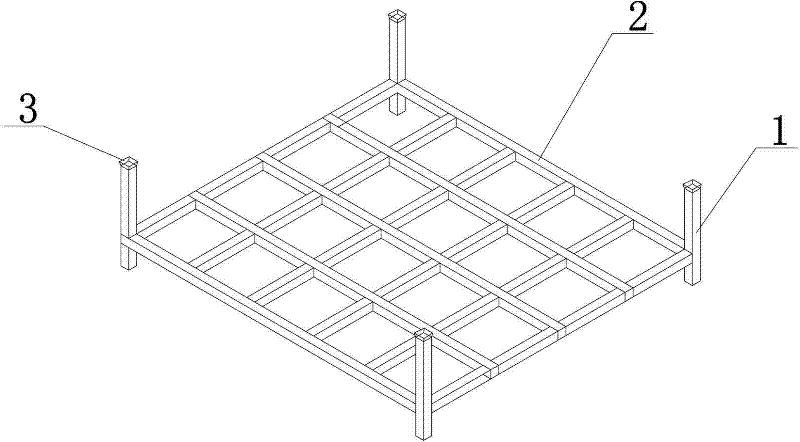

[0014] Such as figure 1 , figure 2 As shown, a three-dimensional composite material rack is characterized in that: it includes a column 1, a support frame 2, and a column spout 3, and the column 1 is connected to four end points of the support frame 2; the column shell Port 3 is connected to the top of the column.

[0015] The support frame 2 is rectangular, and its interior is grid-like.

[0016] The described column pot spout 3 is a cavity structure with a wide top and a narrow bottom.

[0017] The present invention can be moved individually, and multiple supporting frames 2 can be supported by the spout 3 of the column, and can be stacked up to four layers, effectively utilizing storage space, facilitating forklift operation, improving shipping efficiency, and reducing space waste caused by single-layer flat stacking And to avoid the phenomenon of surface crushing caused by material stacking.

[0018] When the present invention is in use, a forklift is used for multi-l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com