Process for hydrolyzing alpha-olefin sulfonate and system for hydrolyzing alpha-olefin sulfonate

An alkenyl sulfonate and process technology, which is applied in the preparation of sulfonate, sulfonic acid, chemical industry, etc., can solve the problems of affecting product quality and heat exchange effect, low energy utilization rate, and product color deepening, etc., to achieve The effect of saving process water consumption, low cost and improving heat transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

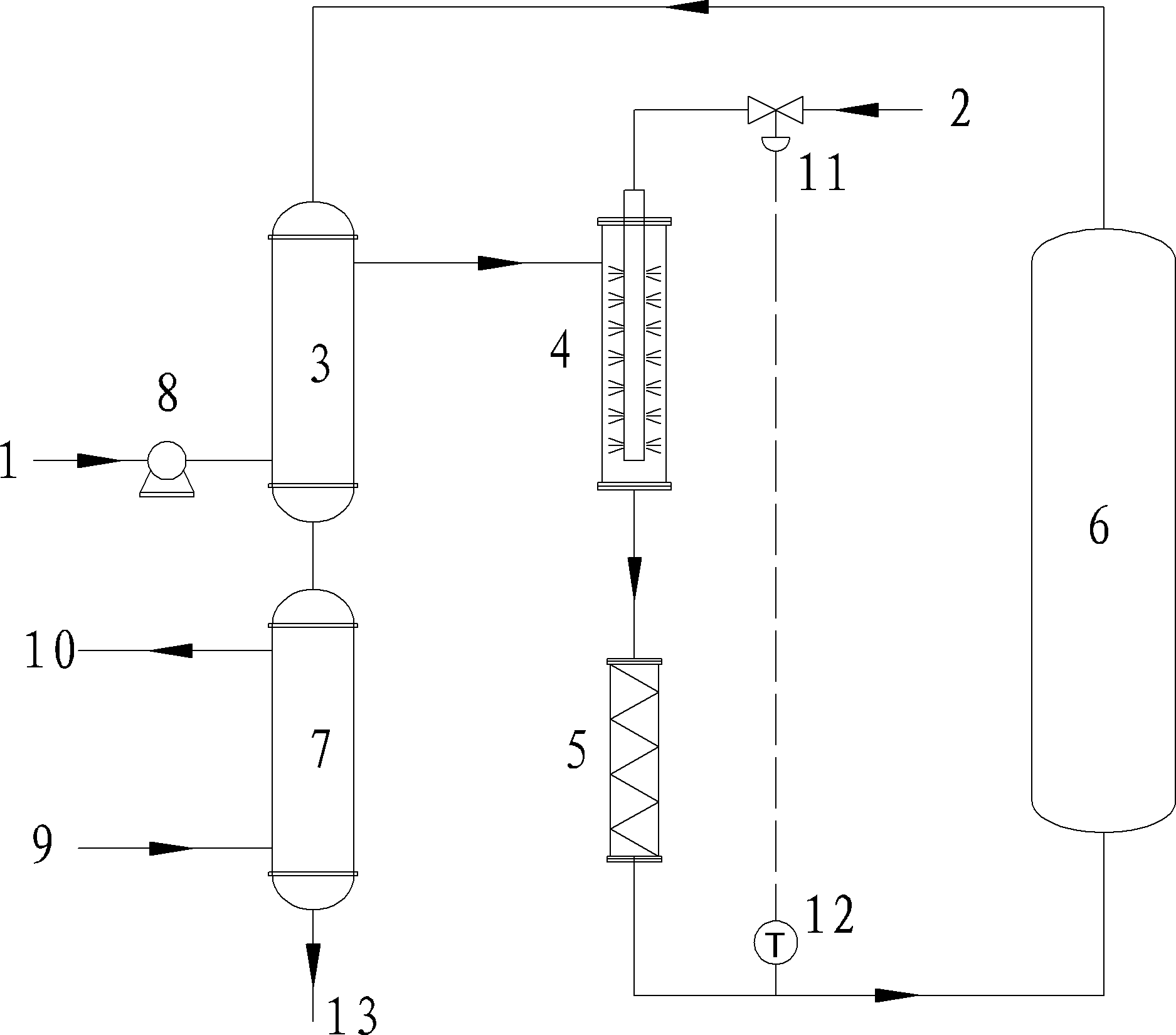

[0040] After sulfonation, aging, and neutralization of α-alkenyl in the 3.8t / h sulfonator, the flow rate is 6750kg / h, the temperature of the neutralization material is 75°C, the pressure of the neutralization discharge is 0.32MPa, and the product is free The alkali content is 2.3%, and the sultone is 51%. The material is pressurized to 0.42 MPa through the booster pump 8, and flows countercurrently with the hydrolyzed alkenyl sulfonate material from the hydrolyzer to exchange heat. ) is directly contacted with steam and heated to 150°C, then enters the hydrolyzer through the static mixer 5, the residence time is 30min, then cools to the outlet at 55°C through the cooler 7, and enters the finished product tank by adding a decolorizing agent to obtain a finished AOS with an active substance content of 35.0 %, free alkali 0.2%, color 50 Hazen, sultone <0.2mg / kg.

Embodiment 2

[0042] After sulfonation, aging, and neutralization of α-alkenyl in a 1.6t / h sulfonator, the flow rate is 2840kg / h, the temperature of the neutralization material is 80°C, and the pressure of the neutralization discharge is 0.35MPa. The alkali content is 2.2%, and the sultone is 49%. The material is pressurized to 0.47 MPa through the booster pump 8, and flows countercurrently with the hydrolyzed alkenyl sulfonate material from the hydrolyzer 6 to exchange heat, and the temperature of the material is raised to 115 ° C; ) in direct contact with steam and heated to 155°C, then enters the hydrolyzer 6 for a residence time of 20 minutes; then passes through the cooler 7 to cool to 55°C for output, adds a decolorizer and enters the finished product tank to obtain a finished AOS with an active substance content of 35.2%, free alkali 0.2%, color 55 Hazen, sultone <0.2mg / kg.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com