Environment-friendly polyether antisludging agent and preparation method thereof

An antiscalant and environmentally friendly technology, applied in the field of industrial circulating cooling water systems, can solve problems such as poor CaCO3 resistance, increased industrial application costs, and difficulty in handling inorganic waste salts, achieving good biodegradability and low production costs , the effect of high inhibitory effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

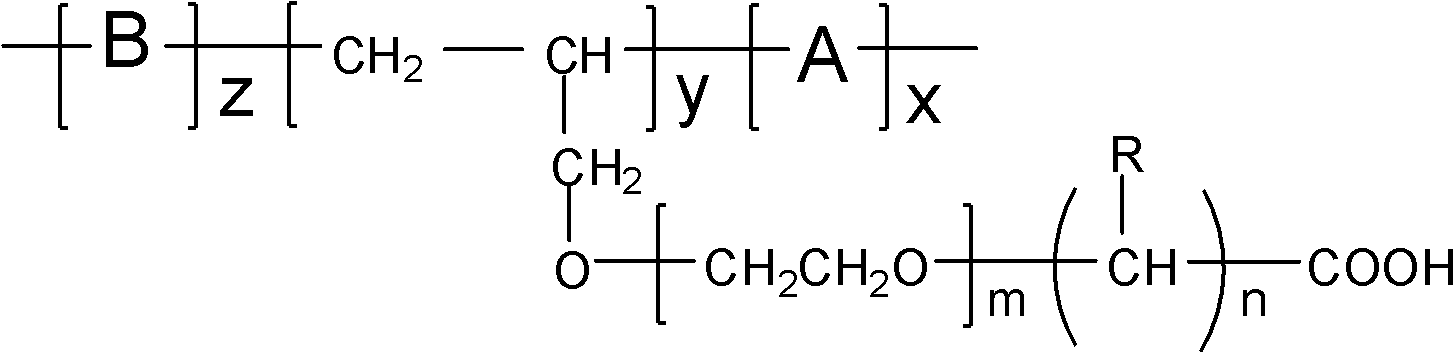

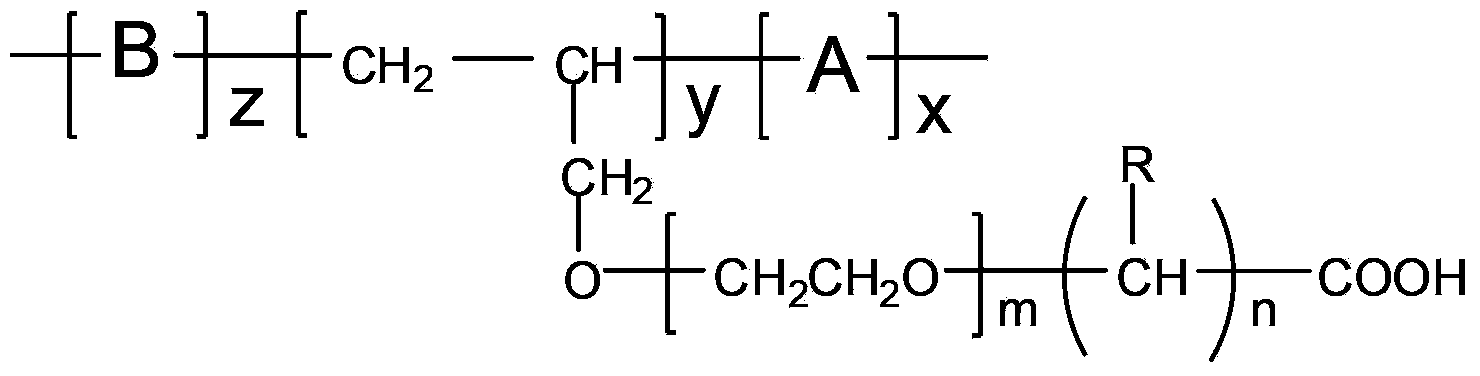

Method used

Image

Examples

example 1

[0022] Example 1: at N 2 Add 100g of allyl polyethylene glycol monoether to the protected reactor, add 80g of γ-butyrolactone and react at 80°C for 2 hours to obtain a polyether carboxylic acid reaction monomer, add 80g of acrylic acid and 100g of hydroxyethyl acrylate at 80°C ester, then add 300g of water, mix well and dropwise add 12g of sodium persulfate (dissolved in 50g of water), dropwise

[0023] After completion, the reaction was continued at 80°C for 3 hours, and after cooling down to room temperature, an environmentally friendly polyether scale inhibitor (APEQ) was obtained. Gained APEQ antiscalant is when dosage is 8mg / L, to Ca 3 (PO 4 ) 2 Scale inhibition rate can reach 99.68%, for CaCO 3 The scale inhibition rate is 93.87%.

example 2

[0024] Example 2: at N 2 Add 100g of allyl polyethylene glycol monoether and 80g of γ-nonanolide to the protected reactor for 3 hours at 60°C to obtain a polyether carboxylic acid reaction monomer, add 60g of acrylic acid and 120g of methacrylic acid at 60°C Hydroxypropyl ester, then add 250g of water, mix well and dropwise add 10g of potassium persulfate (dissolved in 50g of water), after the dropwise addition, raise the temperature to 85°C, continue the reaction for 5h, and after cooling down to room temperature, an environmentally friendly Type polyether antiscalant (APEQ).

[0025] Gained APEQ antiscalant is when dosage is 8mg / L, to Ca 3 (PO 4 ) 2 Scale inhibition rate can reach 99.52%, for CaCO 3 The scale inhibition rate is 94.75%.

example 3

[0026] Example 3: at N 2 Add 120g of allyl polyethylene glycol monoether and 60g of ε-caprolactone to the protected reaction kettle and react at 100°C for 5 hours to obtain a polyether carboxylic acid reaction monomer. After the temperature drops to 75°C, add 100g of maleic acid and 120g of dihydroxypropyl fumarate, then add 300g of water, mix well and dropwise add 15g of sodium persulfate (dissolved in 60g of water), after the dropwise addition, the temperature is raised to 90°C, continue the reaction for 2h, and drop to After room temperature, the environment-friendly polyether scale inhibitor (APEQ) was prepared.

[0027] Gained APEQ antiscalant is when dosage is 8mg / L, to Ca 3 (PO 4 ) 2 Scale inhibition rate can reach 96.54%, for CaCO 3 The scale inhibition rate is 91.17%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| scale inhibition rate | aaaaa | aaaaa |

| scale inhibition rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com