High magnetic induction grain-oriented silicon steel stripe nitriding treatment method

A technology of high magnetic induction orientation and nitriding treatment, applied in coating, metal material coating process, solid-state diffusion coating, etc., can solve the problems of low nitriding efficiency, instability, affecting the stability of secondary recrystallization, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

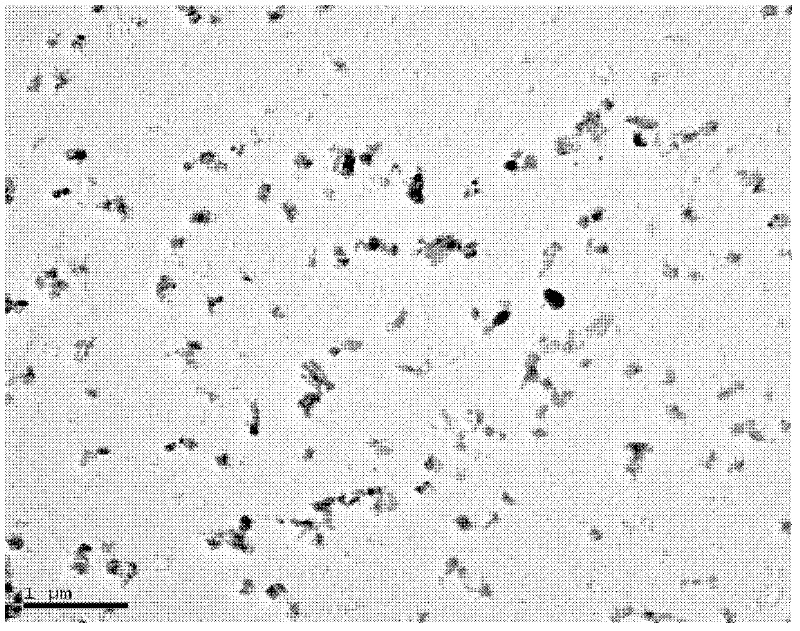

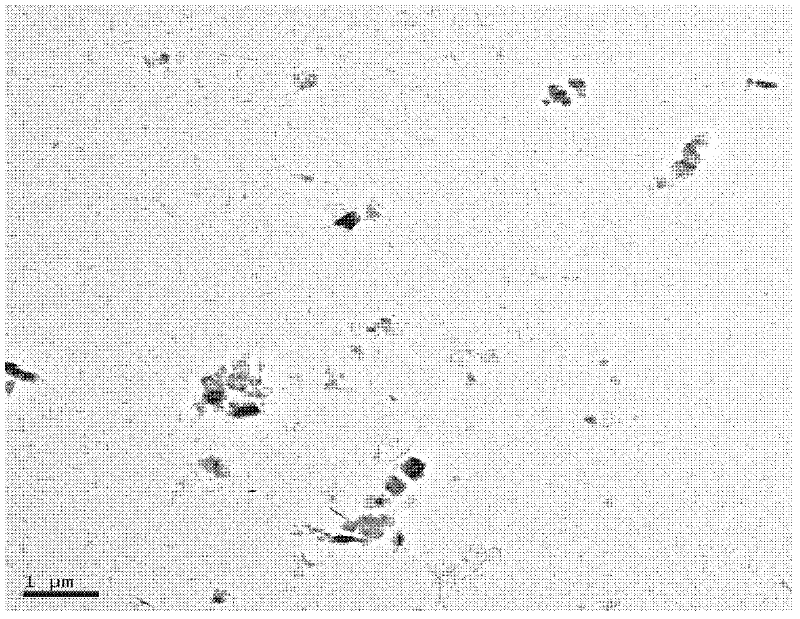

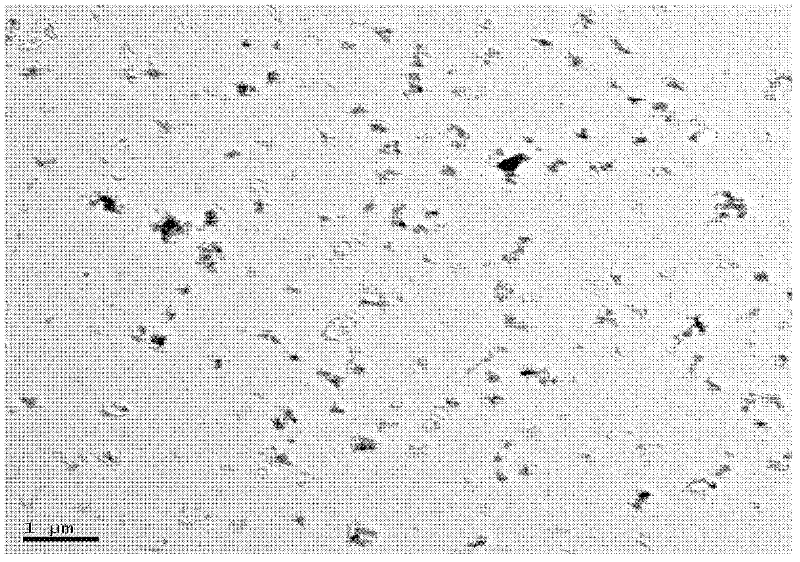

Image

Examples

Embodiment 1

[0038] A nitriding treatment method for high magnetic induction oriented silicon steel strip, the experimental conditions: the thickness of the cast slab is 230mm, the chemical composition and weight percentage of the cast slab are: Si: 3.15%, C: 0.058%; Mn: 0.10%; S: 0.010%; Als: 0.030%; N: 0.0080%; Cu: 0.080%; Sn: 0.053%; Cr: 0.020%; The board thickness is 2.2mm, and the product thickness is 0.23mm.

[0039] Its steps:

[0040] 1) After smelting and continuous casting, the cast slab is heated to 1175-1185°C, hot-rolled to 2.2mm, normalized and cold-rolled, in H 2 and N 2 Carry out decarburization annealing in a dry mixed atmosphere, the decarburization annealing temperature is 825-835°C, the annealing time is 150 seconds, and the final C content in the steel strip is controlled to 19ppm;

[0041] 2) One-time nitriding: in H 2 and N 2 Nitriding is carried out under a dry mixed atmosphere, the nitriding temperature is 840-850 ° C, according to 2.5m 3 / ton of steel into ...

Embodiment 2

[0047] A nitriding treatment method for high magnetic induction oriented silicon steel strip, the experimental conditions: the thickness of the cast slab is 210mm, the chemical composition and weight percentage of the cast slab are: Si: 3.25%, C: 0.055%; Mn: 0.10%; S: 0.009%; Als: 0.032%; N: 0.0050%; Cu: 0.080%; Sn: 0.043%; Cr: 0.040%; The board thickness is 2.3mm, and the product thickness is 0.23mm.

[0048] Its steps:

[0049] 1) After smelting and continuous casting, the billet is heated to 1115-1125°C, hot-rolled to 2.3mm, normalized and cold-rolled. 2 and N 2 Carry out decarburization annealing in a dry mixed atmosphere, the decarburization annealing temperature is 830-840°C, the annealing time is 50 seconds, and the final C content in the steel strip is controlled to 20ppm;

[0050] 2) One-time nitriding: in H 2 and N 2 Nitriding is carried out under dry mixed atmosphere, the nitriding temperature is 790-800°C, according to 2m 3 / ton of steel into NH 3 , and con...

Embodiment 3

[0056] A nitriding treatment method for high magnetic induction oriented silicon steel strip, the experimental conditions: the thickness of the cast slab is 210mm, the chemical composition and weight percentage of the cast slab are: Si: 3.25%, C: 0.065%; Mn: 0.15%; S: 0.009%; Als: 0.032%; N: 0.0040%; Cu: 0.020%; Sn: 0.060%; Cr: 0.020%; The board thickness is 2.3mm, and the product thickness is 0.23mm.

[0057] Its steps:

[0058] 1) After smelting and continuous casting, the cast slab is heated to 1150-1160°C, hot-rolled to 2.3mm, normalized and cold-rolled, in H 2 and N 2 Carry out decarburization annealing in a dry mixed atmosphere, the decarburization annealing temperature is 800-810°C, the annealing time is 180 seconds, and the final C content in the steel strip is controlled to 15ppm;

[0059] 2) One-time nitriding: in H 2 and N 2 Nitriding is carried out under a dry mixed atmosphere, the nitriding temperature is 820-830°C, according to 3.0m 3 / ton of steel into NH...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com