Transmission device of roll brush shaft for sweeper truck

A shaft transmission device and road sweeper technology, which is applied in road cleaning, construction, cleaning methods, etc., can solve the problems of reduced use stability, increased difficulty, and increased failure risk, so as to reduce processing difficulty, improve assembly work efficiency, Avoid rigging complex effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

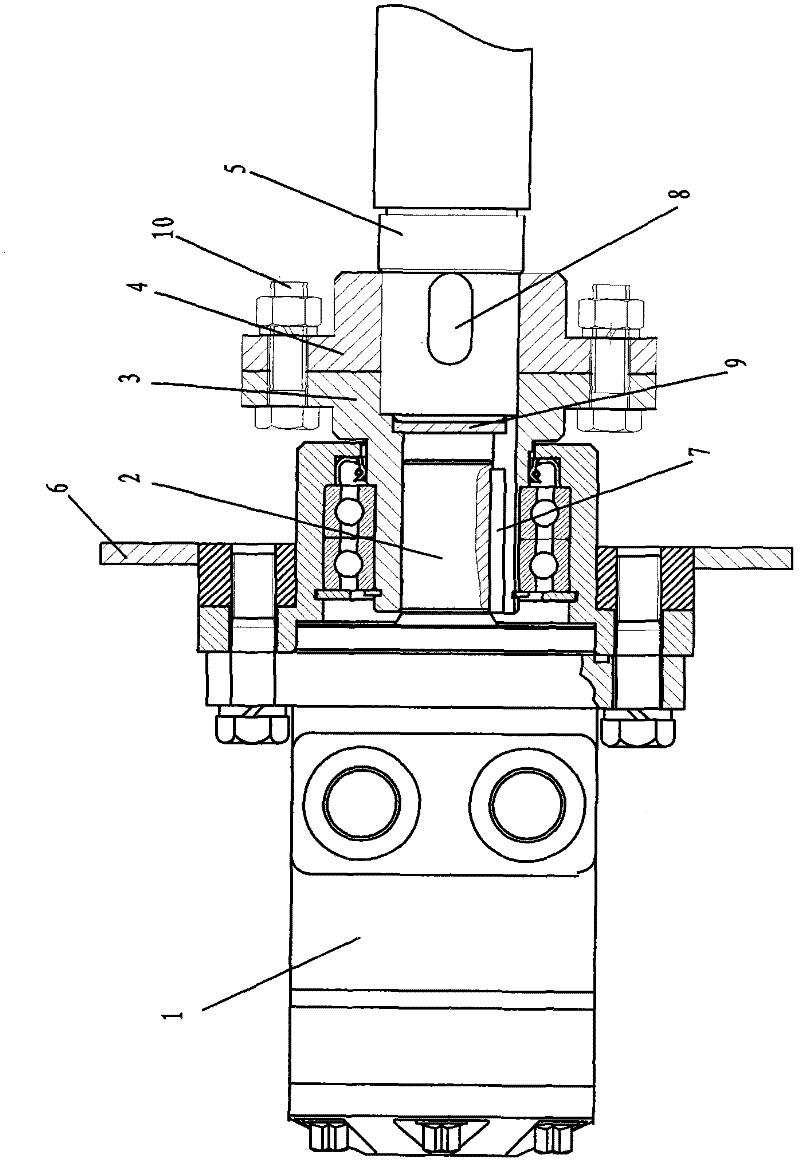

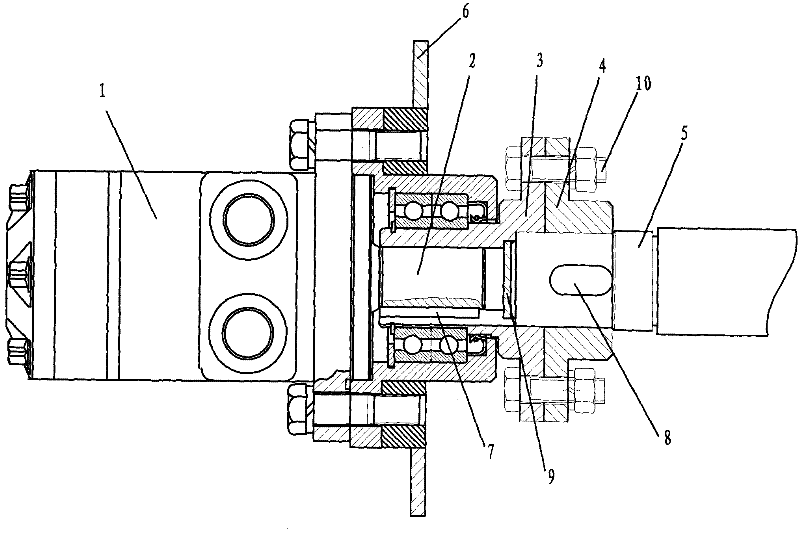

[0013] Such as figure 1 As shown, the present invention is a roller brush shaft transmission device for a road sweeper, including a housing 6, characterized in that: the housing 6 is provided with a hydraulic motor 1, and the hydraulic motor 1 is connected to the motor shaft 2 and the motor shaft 2. The flange plate I 3 is connected to the flange plate I 3 through the key I 7; the flange plate I 3 and the flange plate II 4 are fixedly connected; the flange plate II 4 is connected to the roller brush shaft 5 through the key II 8. The flange I 3 is fixedly connected to the flange II 4 by bolts 10. The flange I 3 is welded with a partition 9 for separating the two cavities. When working, the motor shaft is the drive shaft. The flanges I and II are respectively connected to the motor shaft and the roller brush shaft by keys; the roller brush shaft is inserted between the flanges I and II to play the role of flange connection stop, and bolts are used The connection is fixed to rea...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap