Heavy-duty sliding bearing

A technology for sliding bearings and bearings, which is applied in the direction of bearing components, shafts and bearings, bearing cooling, etc., and can solve problems such as increasing the risk of rotating machinery operation, poor cooling effect, and affecting the service life of bearings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

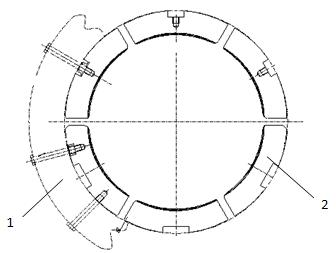

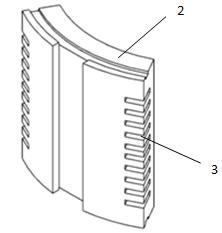

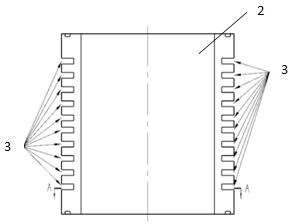

[0011] see Figure 1 to Figure 4 , the heavy-duty sliding bearing includes a bearing seat 1 and a bearing body. The bearing body is composed of a plurality of arc-shaped pads 2 to form a ring and assembled in the bearing seat; the front of the arc-shaped pads 2 is matched with the supported shaft. The back of the arc-shaped tile 2 is matched with the bearing seat 1, and the two sides of the arc-shaped tile are the mating surfaces of adjacent tiles. The bearing has a forced circulation lubricating oil circuit, and the oil path passes through the front and back of the tile; It is characterized in that a number of radial cooling grooves 3 are respectively provided at the corners between the back of the arc tile and the two side surfaces, and the cooling grooves 3 are connected in series in the forced circulation lubricating oil circuit of the bearing.

[0012] For occasions requiring high rotor stability, the arc-shaped pad 2 can also be a tilting pad.

[0013] This structure ne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com