Automobile damper with variable damp of capillary tubes in serial connection

A capillary tube and shock absorber technology, which is applied to shock absorbers, liquid shock absorbers, shock absorbers, etc., can solve the problems of non-adjustable damping characteristics and small adjustable range, and achieves simple and easy technical means and low cost. , the effect of improving the quality of damping characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

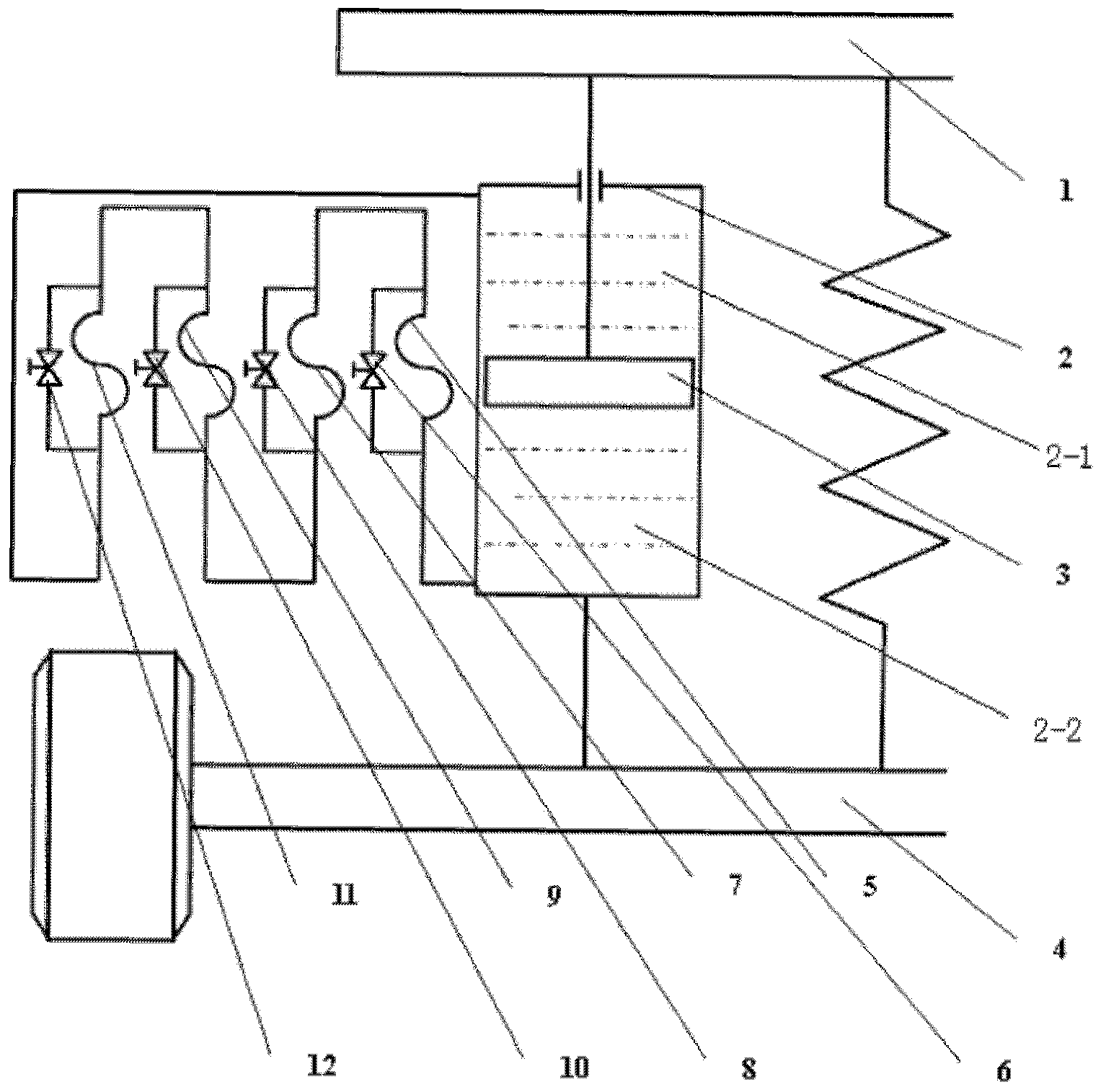

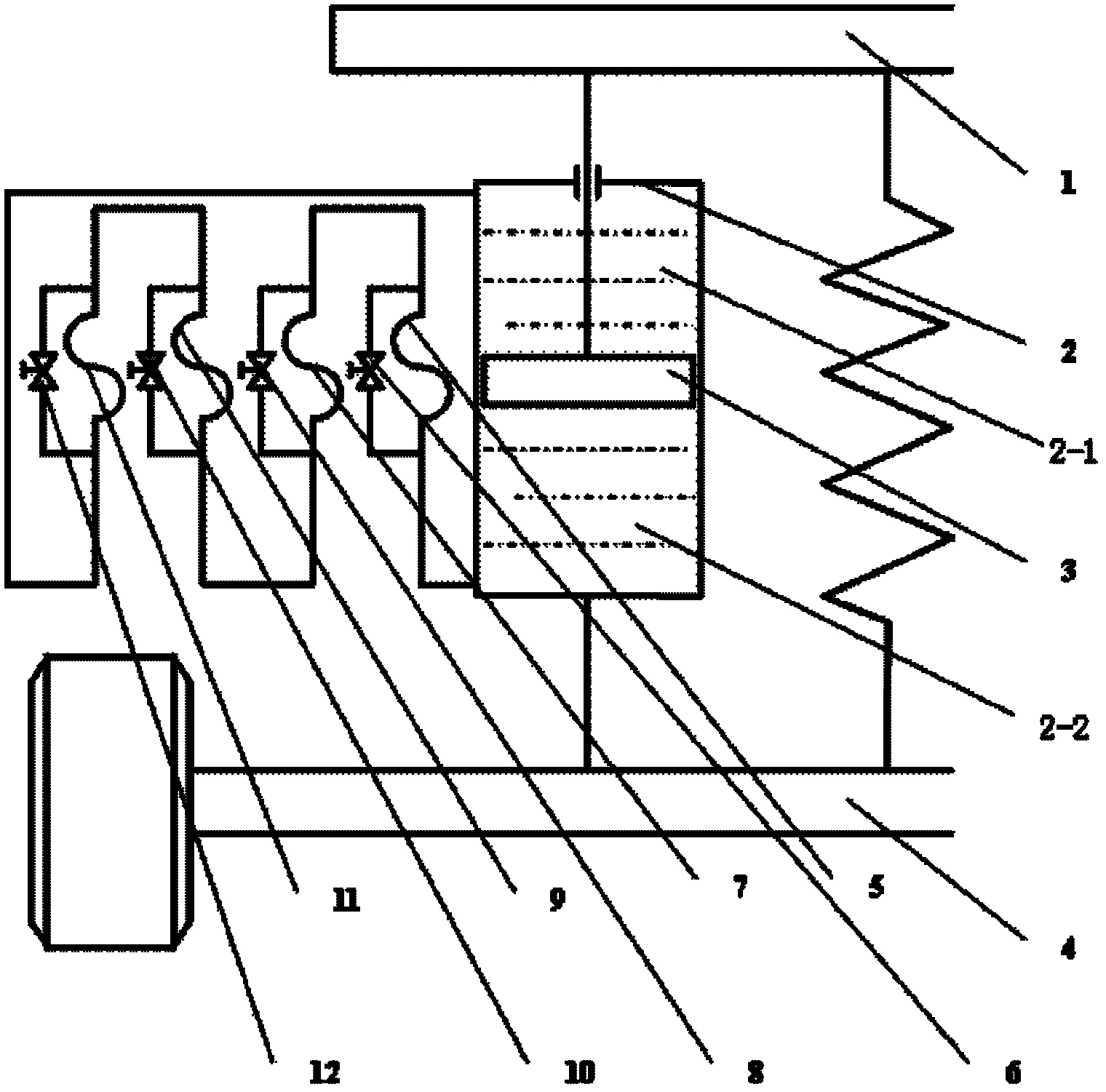

[0023] Such as figure 1 As shown, the automotive shock absorber with capillary variable damping in series in the present invention includes a cylinder body 2 and a piston 3 placed in the cylinder body 2. The inside of the cylinder body 2 is bounded by the piston 3 and is divided into an upper oil tank 2-1 And lower oil tank 2-2, also comprises the capillary tube group that is formed by many capillary tubes 5,7,9,11 connected in series, is all connected in parallel with the electromagnetic valve 6,8,10 that plays by-pass effect at the both ends of every capillary tube 12. The capillary tubes connected in series form two general ports, one of which communicates with the upper oil chamber of the cylinder body, and the other general port communicates with the lower oil chamber of the cylinder body.

[0024] The capillary includes a No. 1 capillary 5, a No. 2 capillary 7, a No. 3 capillary 9 and a No. 4 capillary 11; the solenoid valve includes a No. 1 solenoid valve 6 connected in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com