Ball valve with low-wear seal surface

A technology for ball valves and balls, which is applied to valve devices, cocks including cut-off devices, engine components, etc. It can solve the problem of affecting the service life of ball valves, increasing the wear time of valve seats and ball sealing surfaces, and increasing the sealing surface of valve seats and balls Wear and other problems, achieve the effect of light weight, simple structure and prolong service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

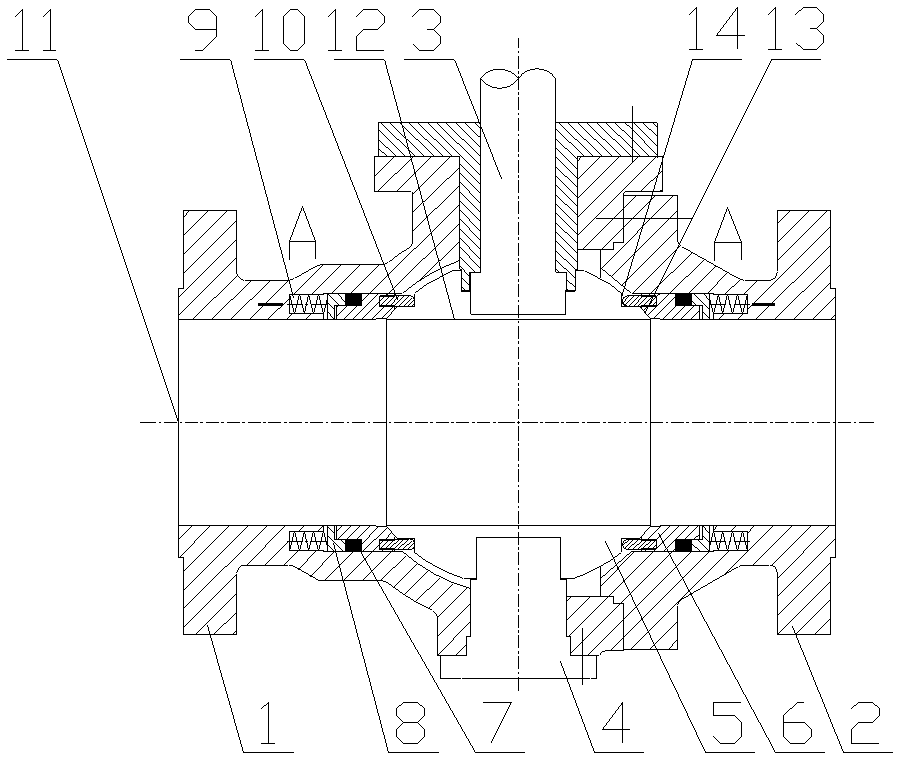

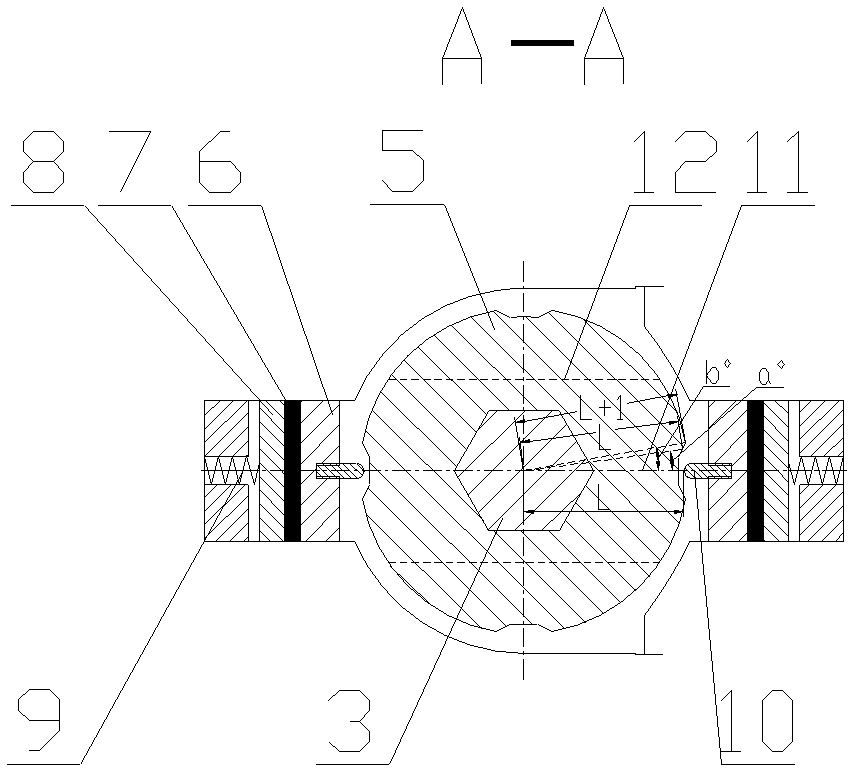

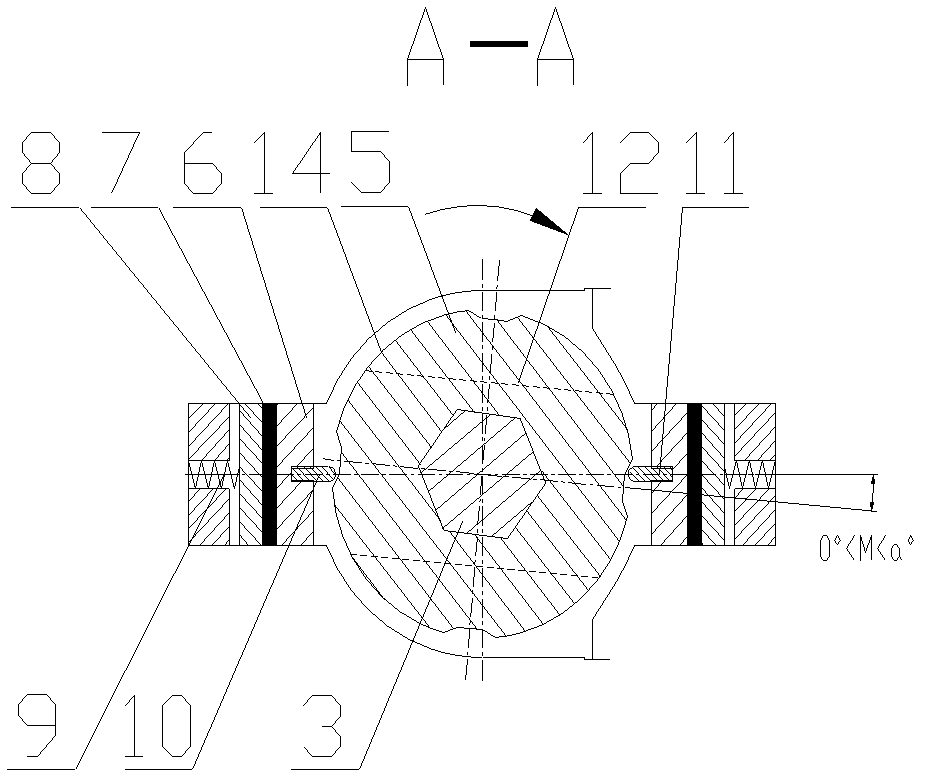

[0017] The present invention will be described in detail below according to the accompanying drawings

[0018] The present invention includes a valve body (in this embodiment, the valve body includes a first valve body part 1 and a second valve body part 2, which are combined with each other to form a complete valve body, but those skilled in the art can obviously know that The valve body structure can also be realized in other ways), valve stem 3, fixed shaft 4, ball 5, valve seat 6, sealing ring 7, pressure ring 8, spring 9, positioning pin 10, such as figure 1 shown. The valve seat 6 has two positioning pins 10 on the upper and lower sides, the positioning pins 10 are fixed on the valve seat 6 in the form of threads, and the upper and lower non-sealing surfaces of the ball 5 are processed into cam shapes. The closing of the ball valve is accomplished by rotating the stem 3 and the ball 5 90° clockwise, through Figure 2-Figure 8 , explains in detail the relative positions...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com