Measuring and controlling device for roasting quality of self-baking electrode of calcium carbide furnace and method

A technology of self-baking electrodes and measurement control, which is applied in measuring devices, using electrical devices, measuring heat, etc., can solve problems such as unpredictable electrode baking temperature and quality, soft breakage of electrodes, and over-baked iron sheets of electrodes, so as to prevent over-baking Iron sheet burning accidents, preventing electrode soft breakage, and improving operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

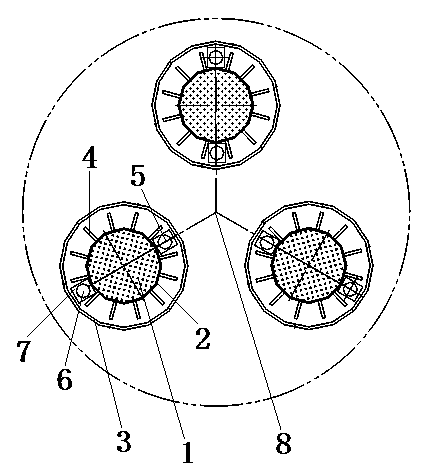

[0017] A measurement and control device for the baking quality of self-baking electrodes of calcium carbide furnaces, such as figure 1 As shown, it includes an electrode 1, an electrode shell 2, an electrode shield 3, a conductive rib 4, an inner thermocouple 5, an outer thermocouple 6, and a high-temperature insulating support 7, etc. in:

[0018] Between the two conductive ribs closest to the high temperature zone 8 in the center of the electric furnace, two inner thermocouples (i.e. temperature sensors) 5 are arranged, which are respectively arranged near the horizontal position of the upper end and the horizontal position of the lower end of the ribs, respectively called Inner upper thermocouple, inner lower thermocouple.

[0019] Between the two conductive ribs farthest from the high temperature zone 8 in the center of the electric furnace, there are two outer thermocouples (i.e. temperature sensors) 6, which are respectively arranged near the horizontal position of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com