Method and device for measuring liquid level of absorption tower

A liquid level measurement device and liquid level measurement technology, applied in the direction of measuring devices, liquid/fluid solid measurement, lubrication indicating devices, etc., can solve the problems of high cost of measuring instruments, inaccurate liquid level measurement of absorption towers, etc., and reduce production Operating cost, low cost, solve the effect of inaccurate measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

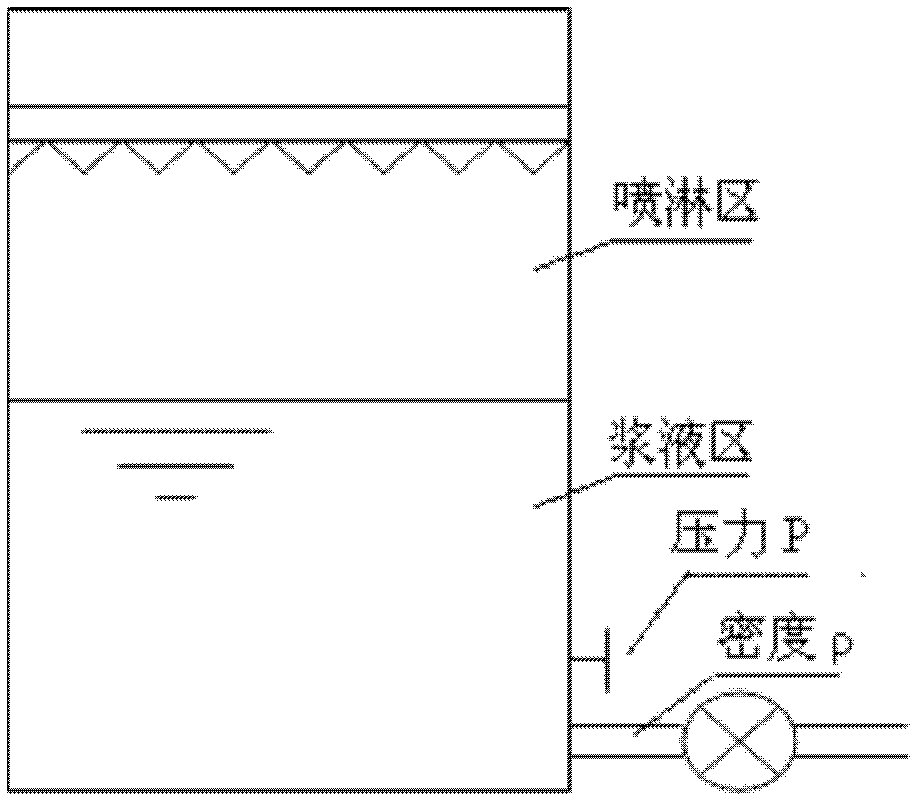

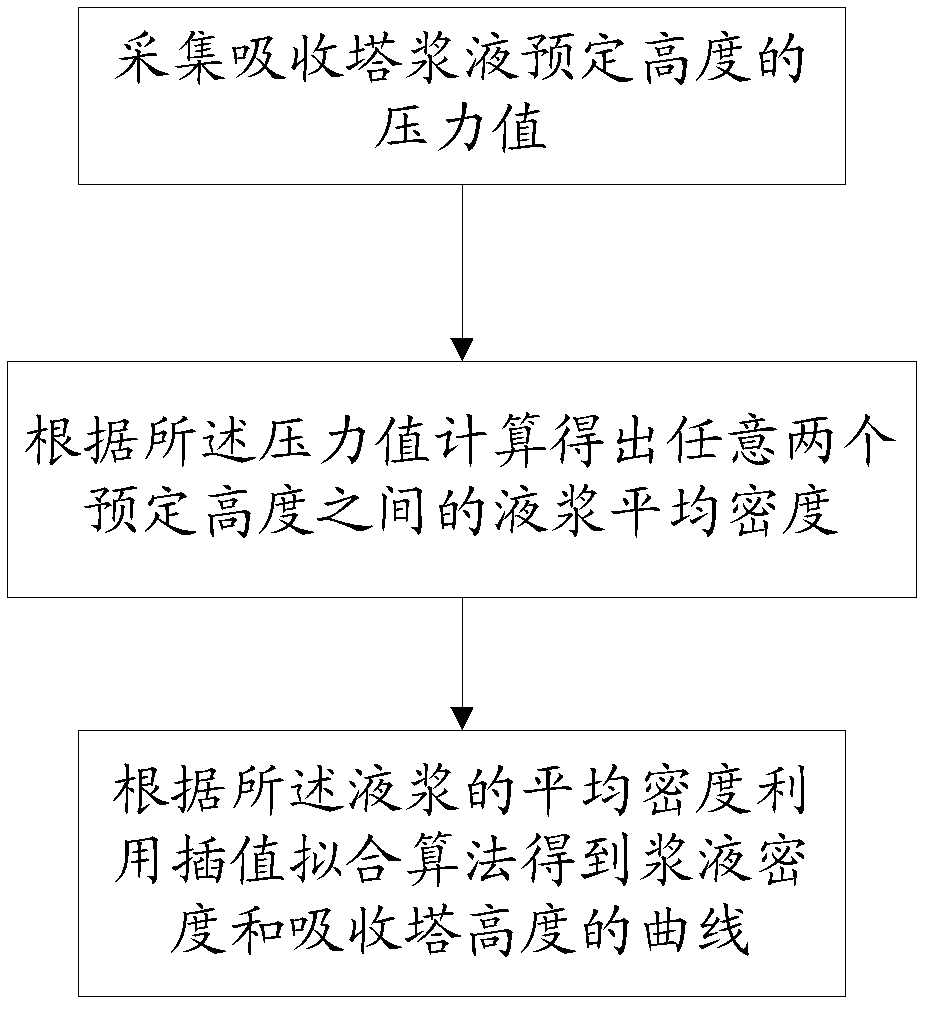

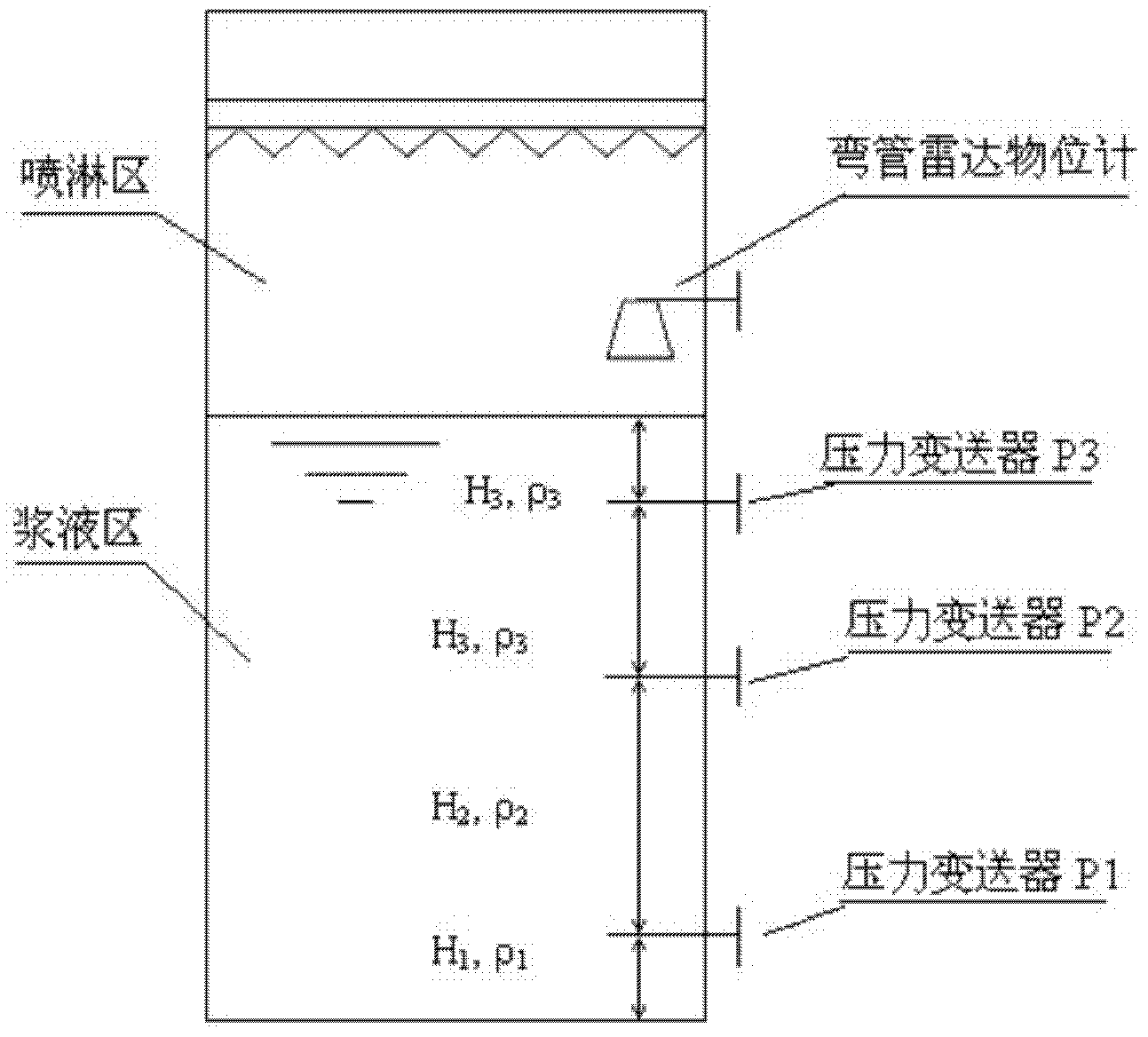

[0027] Please refer to the attached figure 2 And attached image 3 ,in, figure 2 The block diagram of the method for measuring the liquid level of the absorption tower provided by the embodiment of the present invention, image 3 The instrument installation diagram of the liquid level measurement method of the absorption tower provided in the embodiment of the present invention is now taken as an example of collecting the pressure values at the predetermined heights of the slurry in the absorption tower to collect the pressure values at three predetermined heights.

[0028] Use the differential pressure between pressure transmitter 1 and 2 to measure the slurry density ρ2 in section H2;

[0029] ρ 2 = P 1 - P 2 g H 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com