Energy-saving testing device for high-temperature high-pressure performance of down-hole packer

A high temperature and high pressure, test device technology, which is applied in the direction of using liquid/vacuum for liquid tightness measurement and measuring the acceleration and deceleration rate of fluid, etc., can solve problems such as large throttling loss, and achieve small pressure fluctuation and accurate pressure control. , good energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

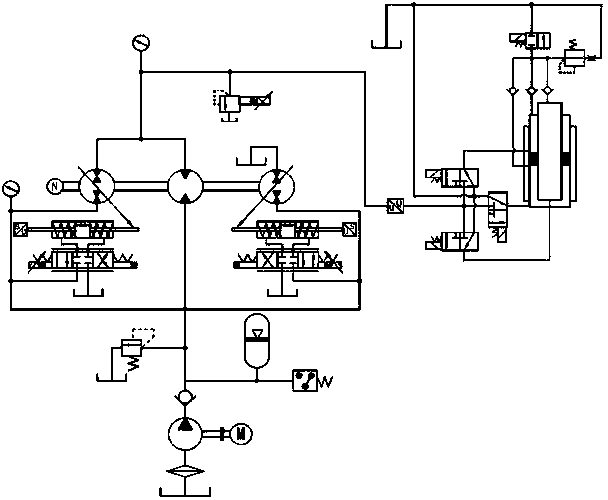

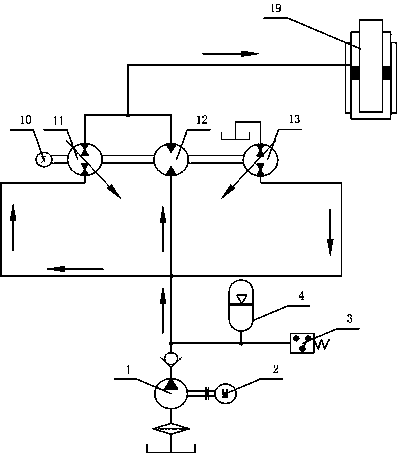

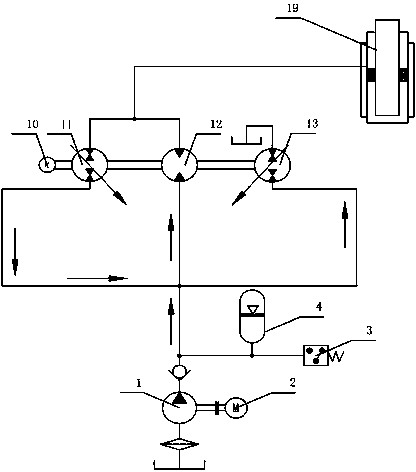

[0022] see figure 1 , the high temperature and high pressure performance test device of the energy-saving downhole packer mainly includes a voltage stabilizing circuit I, a pressurizing circuit II, and a high temperature and high pressure test oil well reversing circuit III; Oil well reversing circuit III is connected sequentially by tubing. The pressure sensor 14 and the pilot-operated high-pressure electro-hydraulic proportional relief valve 15 are respectively connected in parallel on the oil pipe between the pressurization circuit II and the reversing circuit III of the high-temperature and high-pressure test oil well; the flow sensor 16 is connected in series to the pressurization circuit II On the tubing between the high temperature and high pressure test oil well reversing circuit III.

Embodiment 2

[0023] Embodiment 2: This embodiment is basically the same as Embodiment 1, and the special features are:

[0024] see figure 1 The pressure stabilizing circuit I in the energy-saving downhole packer high temperature and high pressure performance test device consists of a pressure relay 3, an accumulator 4 and a direct-acting overflow valve 5 respectively connected in parallel to the oil outlet pipe of the quantitative gear pump 1. It is constructed on the road, and the quantitative gear pump 1 is driven by the motor 2 as the oil source of the system. When the pressure of the oil source is lower than the minimum pressure set by the pressure switch 3, the pressure switch 3 will act to rotate the motor 2 and drive the quantitative gear pump 1 to supply oil to the accumulator 4. When the pressure of the oil source reaches the maximum set by the pressure switch 3 When the pressure is high, the pressure switch 3 acts again to stop the motor from rotating and stop supplying oil to ...

Embodiment 3

[0025] Embodiment 3: This embodiment is basically the same as Embodiment 1, and the special features are:

[0026] see figure 1, the structure of the pressurization circuit II in the energy-saving downhole packer high temperature and high pressure performance test device is a high pressure bidirectional variable pump 11, a high pressure quantitative pump 12 and a low pressure bidirectional variable pump 13 connected coaxially, wherein the high pressure quantitative The pump 12 is located in the middle of the coaxial shaft, and the other two variable variable pumps 11 and 13 are located at both ends of the shaft. One end of the high-pressure bidirectional variable variable pump 11 and the high-pressure quantitative pump 12 is connected to the oil outlet of the pressure stabilizing circuit I, and the other end is connected to the high temperature and high pressure test pump. The oil well reversing circuit III is connected, one end of the low-pressure bidirectional variable pump ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com