Measurement calibration method of falling number tester

A calibration method and measuring instrument technology, applied in food testing, starch contamination testing, material inspection products, etc., can solve the problems of no calibration method and reduced measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The method for measuring and calibrating the falling number measuring instrument of the present invention first places the calibrated measuring instrument in an environment with a room temperature of 10-30°C, the temperature change during the calibration process does not exceed 5°C, and the room temperature and humidity are controlled at 20°C. %~85%RH, there is no magnetic field or mechanical vibration around; then follow the steps below:

[0039] The first step, the calibration of the falling number meter timer

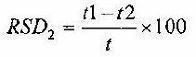

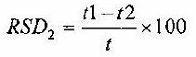

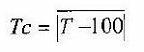

[0040] Simultaneously press the timing switch of the falling number measuring instrument and the stopwatch for calibrating the timing, time 100s, 200s, 300s, and 400s twice each; the accuracy of the timing stopwatch is: the division value is not greater than 0.1s; The time error of the timer t c :

[0041]

[0042] In the formula, t1—the time value measured by the stopwatch; t2—the time value displayed by the falling number measuring instrument;

[0043]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com