Bonding process for reflecting mirror unit of solar condenser

A solar concentrator and reflector technology, applied in the direction of condensing mirrors, optical components, optics, etc., can solve the problems of large bonding positioning error, large area and long curing time, achieve fast bonding and reduce construction costs , the effect of shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0017] 1 Bonding process of silver-plated glass mirror placed horizontally:

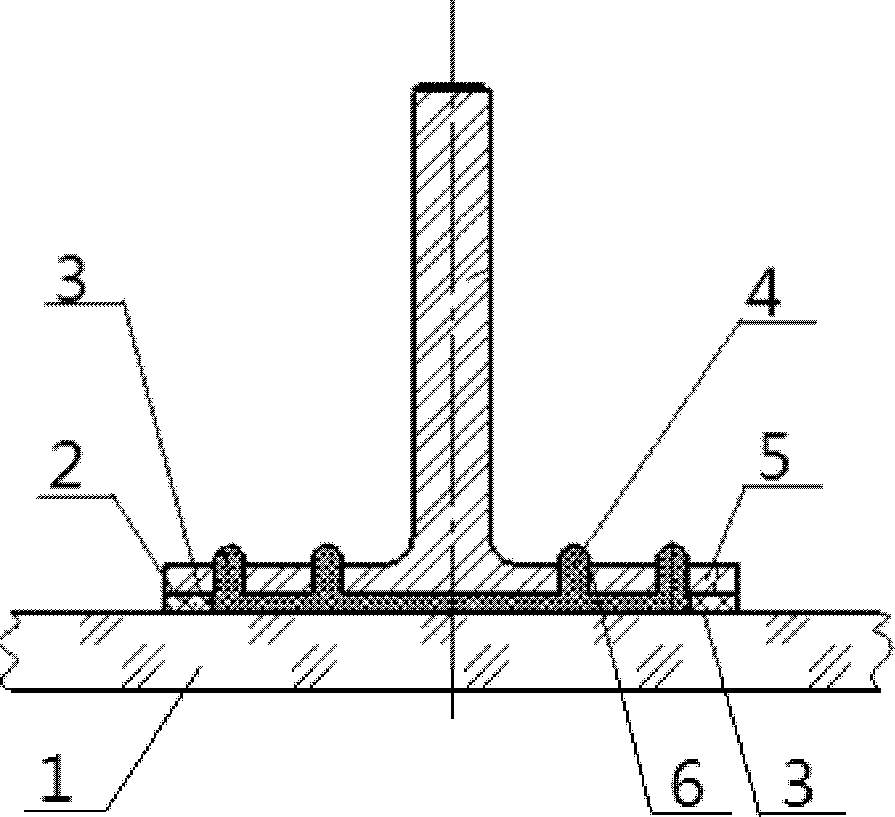

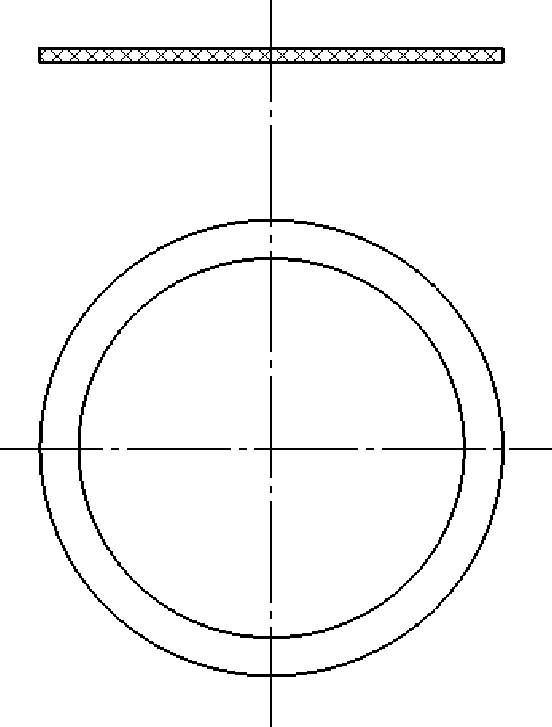

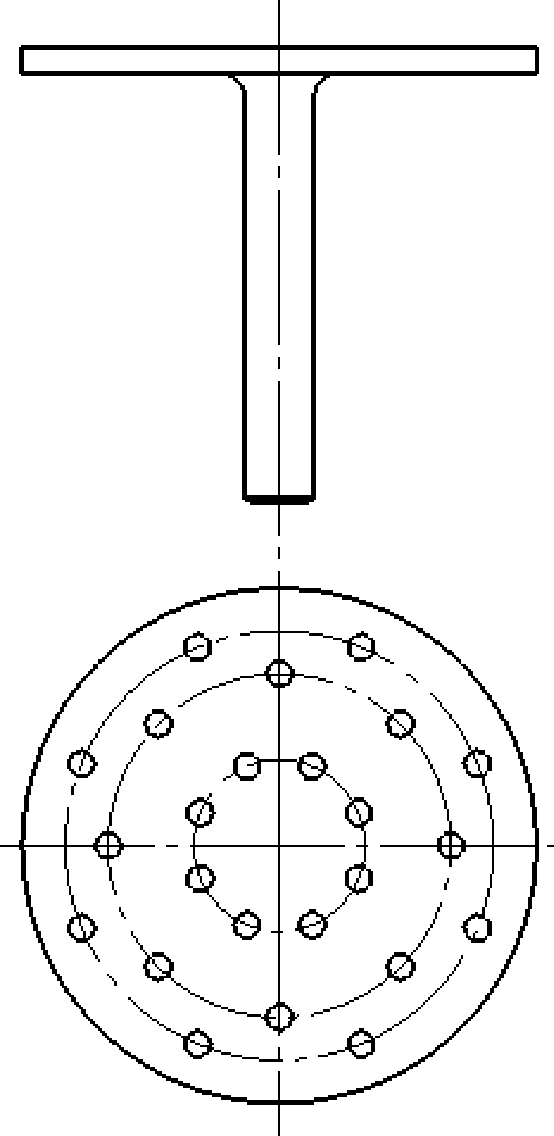

[0018] figure 1 It is a schematic diagram of bonding when the reflector unit of the solar concentrator of the present invention is placed horizontally. The bonding process is as follows: the first step is to place the silver-coated glass mirror 1 horizontally; the second step is to evenly apply instant adhesive 3 on the lower surface of the rubber ring 2, and align the rubber ring 2 with the installation position of the silver-coated glass mirror 1 The bonding is firm; the third step is to inject an appropriate amount of silicone adhesive 4 into the inner ring area of the rubber ring 2 on the silver-plated glass mirror 1; the fourth step is to apply the instant adhesive 3 evenly on the upper surface of the rubber ring 2 and the connector 5 bonding area, connect th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com