Object linking and embedding for process control (OPC)-based general interface system and its control method

A common interface and control method technology, applied in the field of automation and process control, can solve problems such as low efficiency, influence of quality, poor adaptability of process control system, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

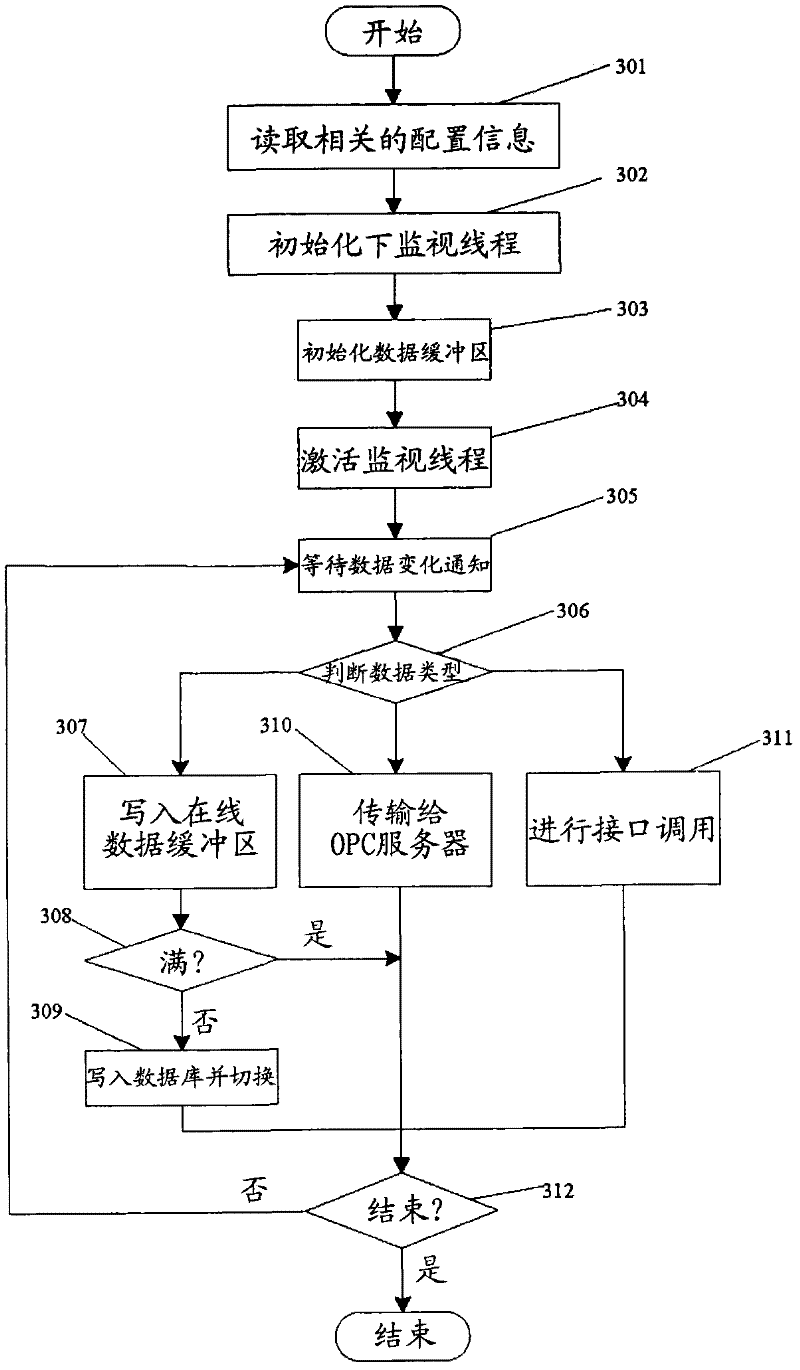

[0027] Embodiments of the invention will now be described in detail, examples of which are illustrated in the accompanying drawings, wherein like reference numerals refer to like parts throughout. The embodiments are described below in order to explain the present invention by referring to the figures.

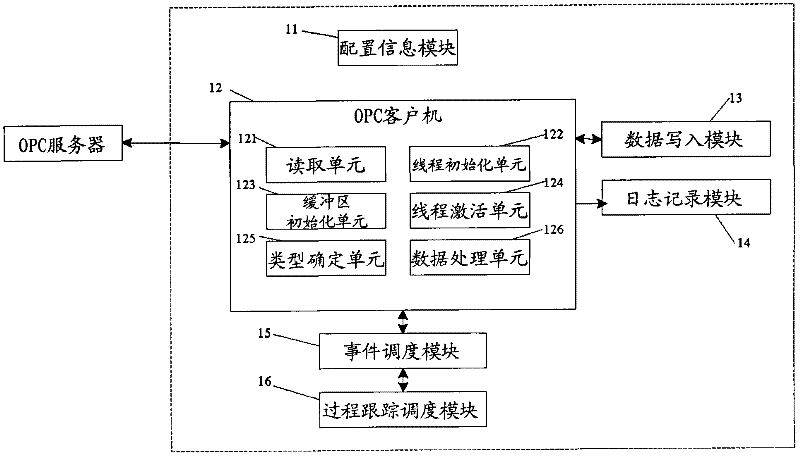

[0028] Below, combine figure 1 and figure 2 The composition of the OPC-based general interface system according to the exemplary embodiment of the present invention will be described in detail.

[0029] refer to figure 1 , the OPC-based general interface system may include a configuration information module 11 , an OPC client 12 , a data writing module 13 , a logging module 14 , an event scheduling module 15 and a process tracking scheduling module 16 .

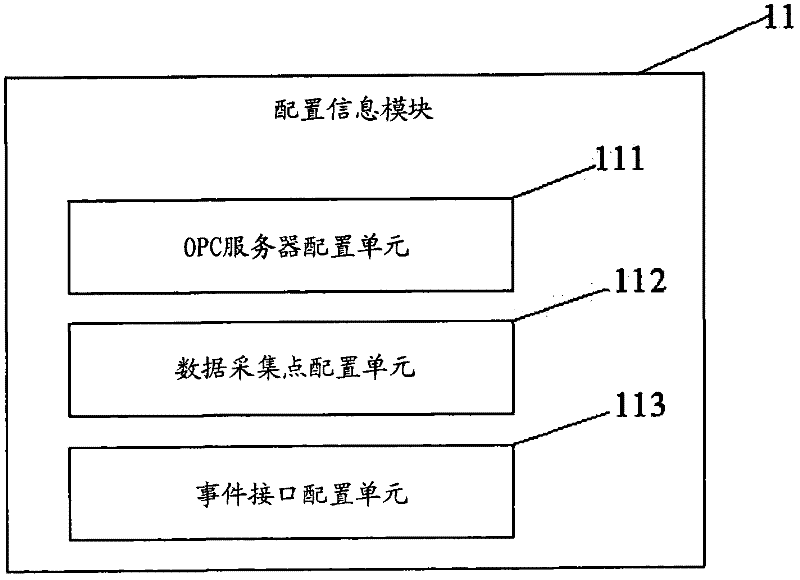

[0030] The configuration information module 11 can be used to store configuration information related to the OPC-based general interface system into a database. According to the present invention, the relevant configurat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com