Controllable filling method for vacuum filling

A vacuum filling and filling technology, applied in capacitor manufacturing, electrical components, liquid filling, etc., can solve the problems of shortened service life, physical health threat, and reduced vacuum degree, and achieves easy operation, low equipment manufacturing cost, and reduced wasteful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

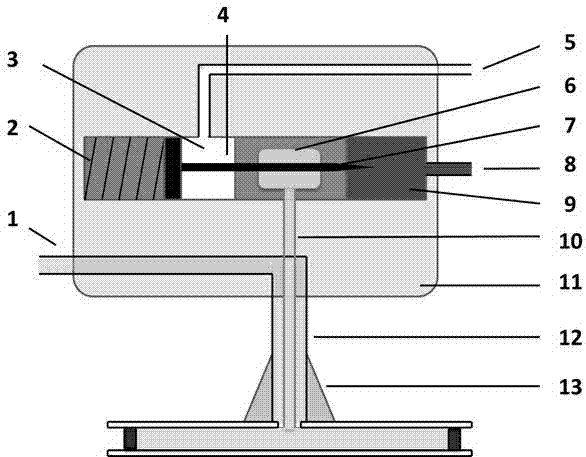

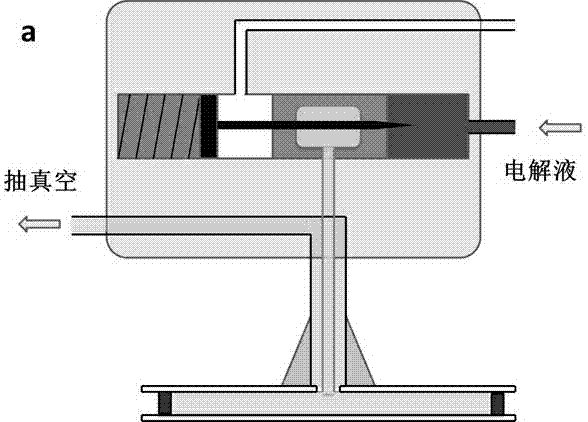

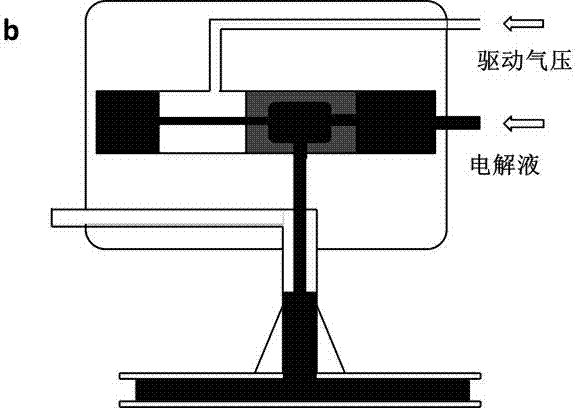

[0024] In order to understand the present invention better, below in conjunction with appendix figure 1 , 2 further describe the present invention.

[0025] like figure 1 As shown, the vacuum filling connection device of the present invention to prevent liquid material from being sucked into the vacuum pump includes a vacuum access pipe (1), a spring piston (2), an external air pressure control chamber (3), a control needle (4), and an external control Air pressure access pipe (5), main control room (6), needle valve (7), liquid material interface to be filled (8), liquid material storage room (9), inner needle (10), controller shell ( 11), outer needle (12), sealing ring (13).

[0026] One end of the external air pressure control chamber (3) is a retainer wall and the other end is a spring piston (2), and there is an opening connected to the external control air pressure access pipe (5), the air pressure control chamber (3) is controlled by the needle (4) Pass through, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com